Inoculating agent for improving machinability of high-strength gray cast iron and preparation method of gray cast iron

A gray cast iron, high-strength technology, applied in the field of metal casting, can solve the problems of increased tool wear and cutting resistance, and achieve the effects of improving cutting life, improving deformation, reducing friction force and wear area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

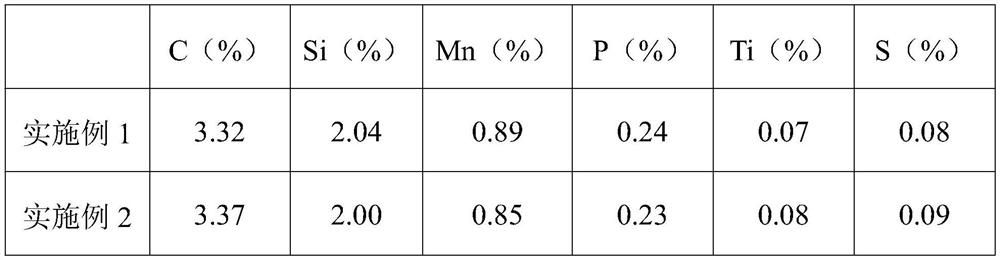

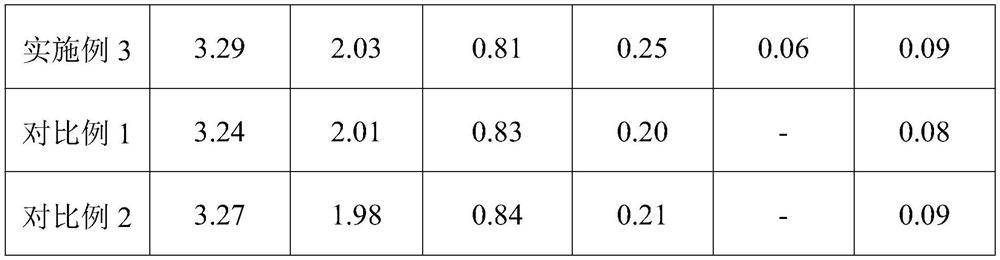

Examples

Embodiment 1

[0024] An inoculant for improving the machinability of high-strength gray cast iron, its chemical composition includes: Si60.5%, Zr7.8%, Ca4.4%, Al2.2%, Ti6.7%, and the rest is Fe.

[0025] The preparation method of above-mentioned inoculant comprises:

[0026] The raw materials of ferrosilicon, silicon-calcium, silicon-zirconium, silicon-aluminum and titanium are calculated according to the chemical composition and the proportion and weight of each raw material, and put into an intermediate frequency induction furnace for melting. The melting temperature is 1340 ° C and the time is 20 minutes; melting After it is completely melted, pour the alloy liquid into a metal mold to cool, and the alloy solidifies in the mold to form a flake alloy; the flake alloy is broken into 2-6mm particles by crushing equipment, which is the improved high-strength gray cast iron Processing inoculants.

[0027] A kind of high-strength gray cast iron, its preparation method comprises the steps:

...

Embodiment 2

[0032] An inoculant for improving the machinability of high-strength gray cast iron, the chemical composition of which includes 55.4% Si, 9.7% Zr, 2.2% Ca, 2.9% Al, 5.3% Ti, and the rest is Fe.

[0033] The preparation method of above-mentioned inoculant comprises:

[0034] The raw materials of ferrosilicon, silicon-calcium, silicon-zirconium, silicon-aluminum and titanium are calculated according to the chemical composition and the proportion and weight of each raw material, and put into an intermediate frequency induction furnace for melting. The melting temperature is 1340 ° C and the time is 20 minutes; melting After it is completely melted, pour the alloy liquid into a metal mold to cool, and the alloy solidifies in the mold to form a flake alloy; the flake alloy is broken into 2-6mm particles by crushing equipment, which is the improved high-strength gray cast iron Processing inoculants.

[0035] A kind of high-strength gray cast iron, its preparation method comprises t...

Embodiment 3

[0040] An inoculant for improving the machinability of high-strength gray cast iron, its chemical composition includes: Si64.5%, Zr6.1%, Ca5.8%, Al1.3%, Ti7.9%, the rest is Fe.

[0041] The preparation method of above-mentioned inoculant comprises:

[0042] The raw materials of ferrosilicon, silicon-calcium, silicon-zirconium, silicon-aluminum and titanium are calculated according to the chemical composition and the proportion and weight of each raw material, and put into an intermediate frequency induction furnace for melting. The melting temperature is 1340 ° C and the time is 20 minutes; melting After it is completely melted, pour the alloy liquid into a metal mold to cool, and the alloy solidifies in the mold to form a flake alloy; the flake alloy is broken into 2-6mm particles by crushing equipment, which is the improved high-strength gray cast iron Processing inoculants.

[0043] A kind of high-strength gray cast iron, its preparation method comprises the steps:

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com