Rotary knife rest for cutting aerated concrete

A technology of aerated concrete and rotating tool rest, applied in the field of tool rest, can solve the problems of consuming a large amount of time, reducing work efficiency, affecting production rhythm, etc., and achieving the effect of reducing the degree of damage and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

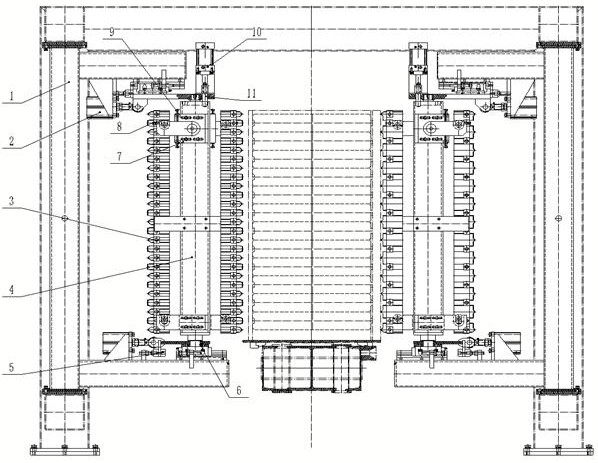

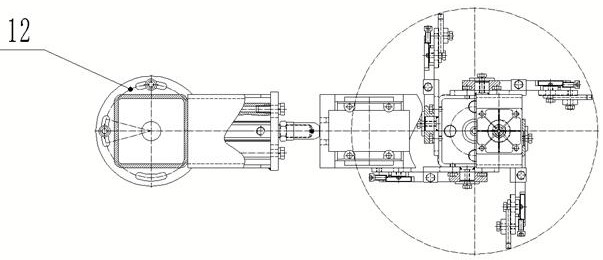

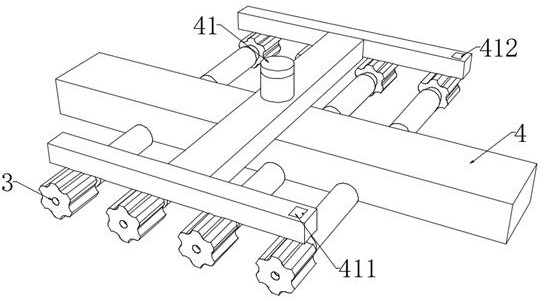

[0036] see Figure 1-6 , a rotary tool holder based on cutting aerated concrete, including a mounting frame 1, four mutually symmetrical cylinder pushing components 2 are installed on the inner wall of the mounting frame 1, and a rotary tool frame 4 is fixedly connected between the inner walls of the cylinder pushing components 2, The rotary tool rest 4 is provided with a cooling mechanism, the lower end of the rotary tool rest 4 is equipped with a cutter 3, the inner wall of the mounting frame 1 is equipped with a positioning cylinder assembly 10, and the positioning cylinder assembly 10 is rotationally connected with the rotary knife rest 4, and the cylinder pushes the assembly 2 One end close to the rotary knife rest 4 is fixedly connected with a buffer block 5, and two mutually symmetrical rotating copper sleeves 6 are installed at the inner bottom of the mounting frame 1, and the rotating copper sleeve 6 is connected to the rotary knife rest 4 in rotation, and the rotary k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com