Deep sea natural gas hydrate strip partition mining method

A technology for zoned mining and natural gas, which is applied in the fields of mining fluid, earthwork drilling, climate sustainability, etc. It can solve the problems of low mining efficiency and achieve the effect of improving mining efficiency, clear design ideas, and stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

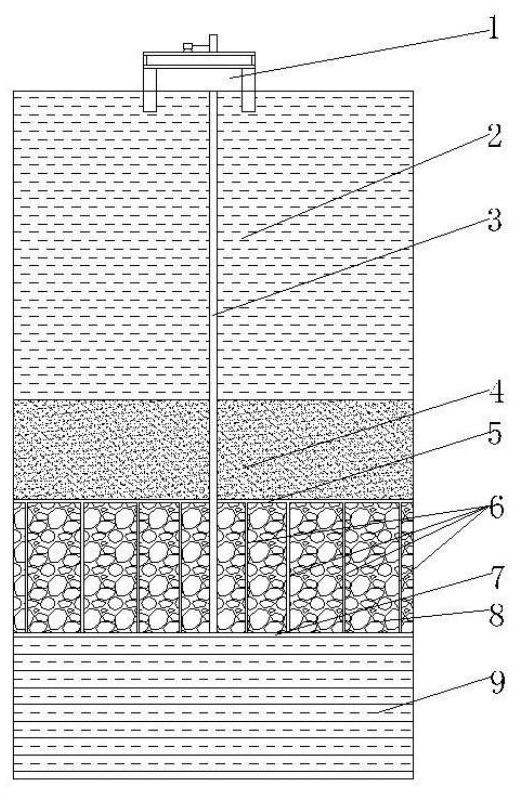

[0059] Analyze the formation permeability coefficient, formation temperature and particle gradation geological parameters in the area where the natural gas hydrate is located, determine the height of the seawater layer, the suitable position for the main vertical well 3, the thickness of the overburden layer 4, and the symmetrical length range of the strip mining area with respect to the main vertical well 3 ; The specific data is that the seawater depth is 800m, the overburden thickness is 200m, and the formation permeability coefficient is 1.5×10 -4 cm / s, formation pressure 12MPa, average particle size of formation particles 500μm;

[0060] Build the offshore production platform 1 and the main shaft 3 according to the above parameters; build the main shaft 3 through the overburden layer 4 to the height where the overburden layer 4 connects with the natural gas hydrate reservoir 8, and extend downward to the natural gas hydrate reservoir 8 ; According to the above parameters,...

Embodiment 2

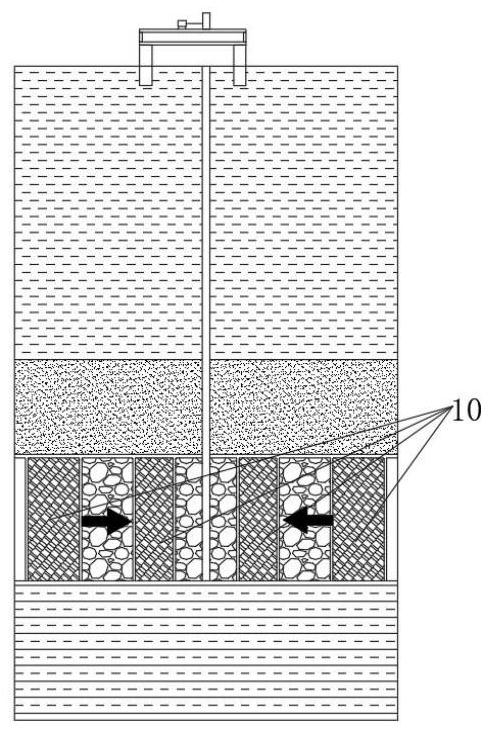

[0066] The only difference between this embodiment and the first embodiment is that, for example, image 3 , the mining method is a schematic diagram of advancing mining at intervals. First, the above-mentioned mining vertical well 6 is used to mine two mining strips on both sides of the main vertical well 3, and the horizontal well 7 for lowering the energy supplying strip is used to reduce the mining strip away from the main vertical well 3. The interior of the mining vertical well 6 side Fluid pressure, the natural gas generated by decomposition is transported to the offshore exploitation platform 1 through the upper recovery horizontal well 5 and the main vertical well 3 .

[0067] Further, when the productivity of the two mining strips on both sides of the main vertical shaft 3 is significantly reduced and cannot meet the commercial production requirements, the next operating mining strip is mined from the main vertical shaft 3 to the edge direction of the strip mining are...

Embodiment 3

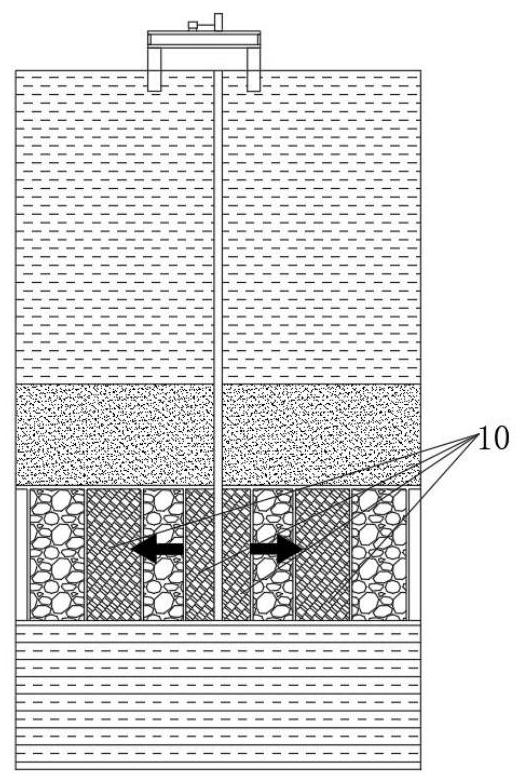

[0070] The only difference between this embodiment and the first embodiment is that, for example, Figure 4 , for the two sides to retreat in sequence at the same time; when the productivity of the two mining strips near the edge of the mining area is significantly reduced and cannot meet commercial mining, the mining strips are successively mined in the direction close to the vertical well 3 until the vertical well 3.

[0071] The difference between the effect of this embodiment and the first embodiment is that when the geological conditions of the mining area are good and the seabed stratum is relatively stable, the method of this example is used for mining. Relatively large, the economic benefits are obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com