Method for evaluating storage stability of adhesive

A technology of storage stability and evaluation method, applied in the field of evaluation of the storage stability of adhesives, can solve problems such as long time consumption, and achieve the effects of reducing test time, solving long time consumption, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

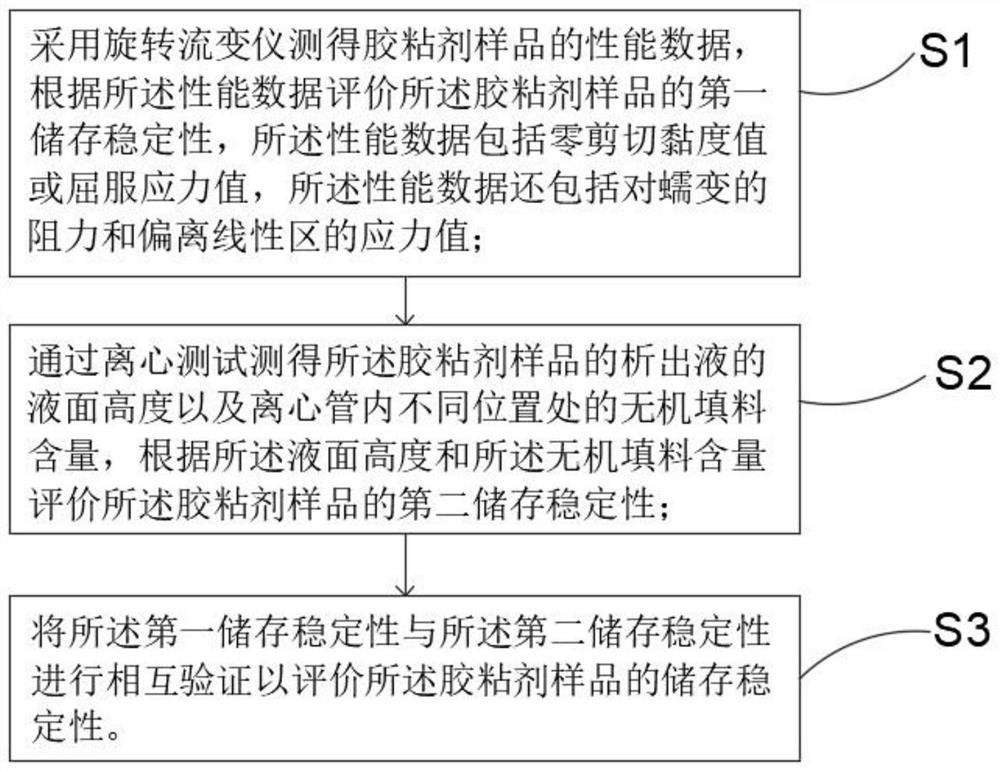

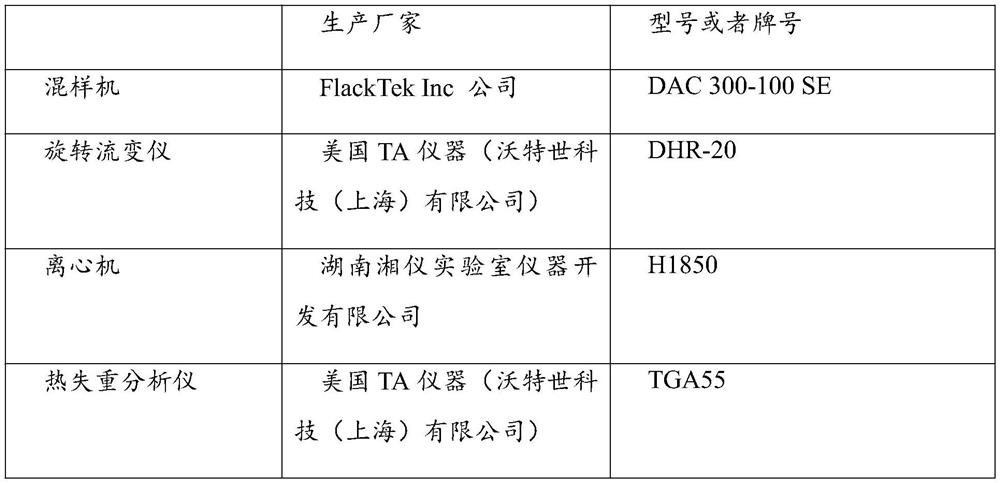

Method used

Image

Examples

Embodiment 1

[0052] Accurately measure sample 1, sample 2, and sample 3 respectively, put them into three sample cups, then put the three sample cups into the sample mixer, and mix them evenly by vacuuming to eliminate the influence of air bubbles on the later test , the mixing speed is 2000 rpm, and the time is 2 minutes. After mixing, take out sample 1 to be evaluated, sample 2 to be evaluated and sample 3 to be evaluated;

[0053] The rheological curve of the sample 1 to be evaluated, the rheological curve of the sample 2 to be evaluated and the rheological curve of the sample 3 to be evaluated are measured by a rotational rheometer, because the sample to be evaluated 1. The sample 2 to be evaluated and the sample 3 to be evaluated are both yield stress fluids, so the sample 1 to be evaluated, the sample 2 to be evaluated and the sample to be evaluated are obtained according to the steady state scanning test mode. The change curve of the shear stress of the sample 3 evaluated with the s...

Embodiment 2

[0058] Weigh the sample to be evaluated 1, the sample to be evaluated 2, the sample to be evaluated 3 and water of the same quality into a centrifuge tube, tighten the cap, and put the four centrifuge tubes into the centrifuge symmetrically. In the machine casing; set the centrifuge condition, the centrifuge speed in the centrifuge condition is 9000rpm, and the centrifugation time is 30min; start the centrifuge, after the separation is finished, open the centrifuge cover, take out the centrifuge to be evaluated The sample 1, the sample to be evaluated 2 and the sample to be evaluated 3;

[0059] Measure the minimum liquid level height and the maximum liquid level height of the eluate of the sample 1 to be evaluated, the sample 2 to be evaluated and the sample 3 to be evaluated, and the specific values are shown in Table 3;

[0060] The liquid level is equal to the maximum liquid level minus the minimum liquid level.

[0061] The centrifuge tube containing the sample 1 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com