Quality improver for river crab culture as well as preparation method and application of quality improver

A quality improver, the technology of river crab, applied in application, fish farming, food processing, etc., can solve the problem of poor quality of drug-resistant river crab, meet the requirements of nutrition and antibacterial properties, and reduce drug resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

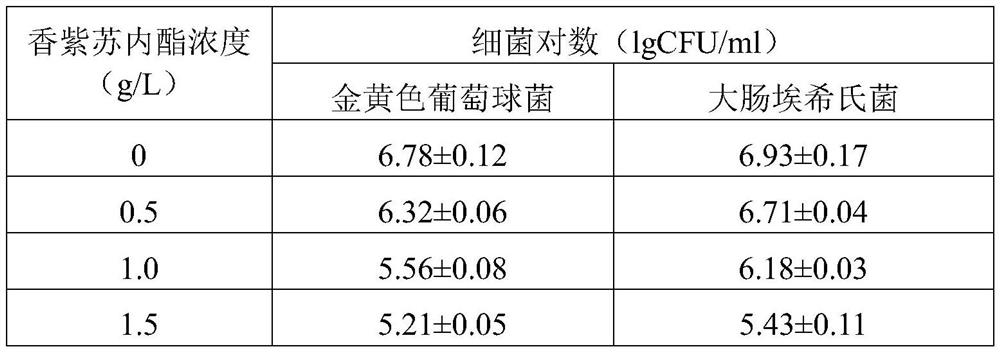

[0020] The quality improver for river crab culture described in this embodiment includes the following components by weight: 10 parts by weight of fish meal, 15 parts by weight of soybean meal, 5 parts by weight of peanut meal, 12 parts by weight of cotton meal, 10 parts by weight of rapeseed meal, 8 parts by weight of aquatic yeast powder, 3 parts by weight of citric acid residue, 30 parts by weight of corn flour, 1 part by weight of soybean lecithin, 3 parts by weight of squid paste, 2 parts by weight of bentonite, 3 parts by weight of calcium dihydrogen phosphate, sclareolide 3 parts by weight.

Embodiment 2

[0022] The quality improver for river crab culture described in this embodiment includes the following components by weight: 20 parts by weight of fish meal, 5 parts by weight of soybean meal, 12 parts by weight of peanut meal, 5 parts by weight of cotton meal, 15 parts by weight of rapeseed meal, 3 parts by weight of aquatic yeast powder, 8 parts by weight of citric acid residue, 20 parts by weight of corn flour, 3 parts by weight of soybean lecithin, 1 part by weight of squid paste, 5 parts by weight of bentonite, 1 part by weight of calcium dihydrogen phosphate, sclareolide 8 parts by weight.

Embodiment 3

[0024] The quality improver for river crab culture described in this embodiment includes the following components by weight: 15 parts by weight of fish meal, 10 parts by weight of soybean meal, 8 parts by weight of peanut meal, 8 parts by weight of cotton meal, 12 parts by weight of rapeseed meal, 5 parts by weight of aquatic yeast powder, 5 parts by weight of citric acid residue, 25 parts by weight of corn flour, 2 parts by weight of soybean lecithin, 2 parts by weight of squid paste, 3 parts by weight of bentonite, 2 parts by weight of calcium dihydrogen phosphate, sclareolide 5 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com