Glutinous rice food and preparation method thereof

A technology of glutinous rice and food, applied in the direction of food ingredients, food ingredients as thickeners, food science, etc., can solve the problems of loss of viscoelasticity, difficulty in chewing, and hardening, and achieve the effect of not aging easily and maintaining the taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

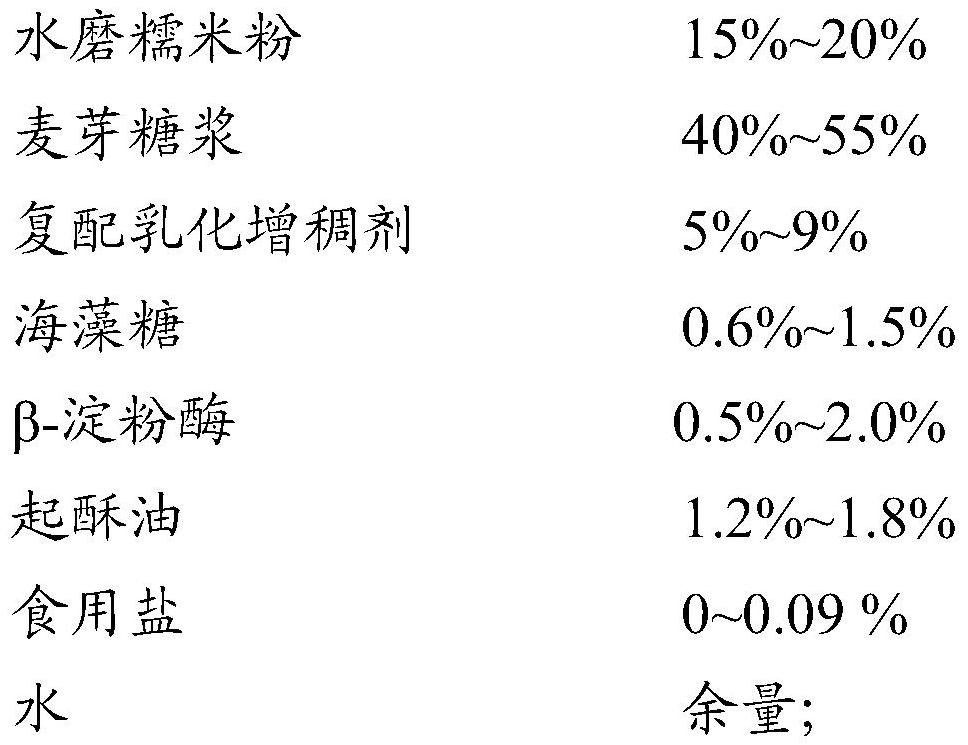

[0054] The present embodiment glutinous rice cake skin material (total weight 20kg):

[0055] Glutinous rice flour A (water mill, gelatinization temperature 59.92°C, aging degree 4.31) 3.50kg, maltose syrup (glucose equivalent value 70) 10.00kg, compound emulsification thickener 1.5kg, trehalose 0.25kg, β-amylase 0.20 kg, shortening 0.30kg, drinking water 4.25kg.

[0056] The preparation method of the glutinous rice cake skin layer of the present embodiment comprises:

[0057] Mix the weighed compound emulsion stabilizer with glutinous rice flour;

[0058] Dissolve the enzyme preparation in drinking water according to the quality of 1:5, add it to the drinking water of the steamer after mixing, stir and mix well, then add the mixed dry material, stir for 5 minutes and mix until there is no dry powder. , cover the top cover, open and stir through the steam (pressure 0.005MPa), steam for 5min, then adjust the pressure to 0.03Mpa, continue steaming for 15min. After steaming, t...

Embodiment 2

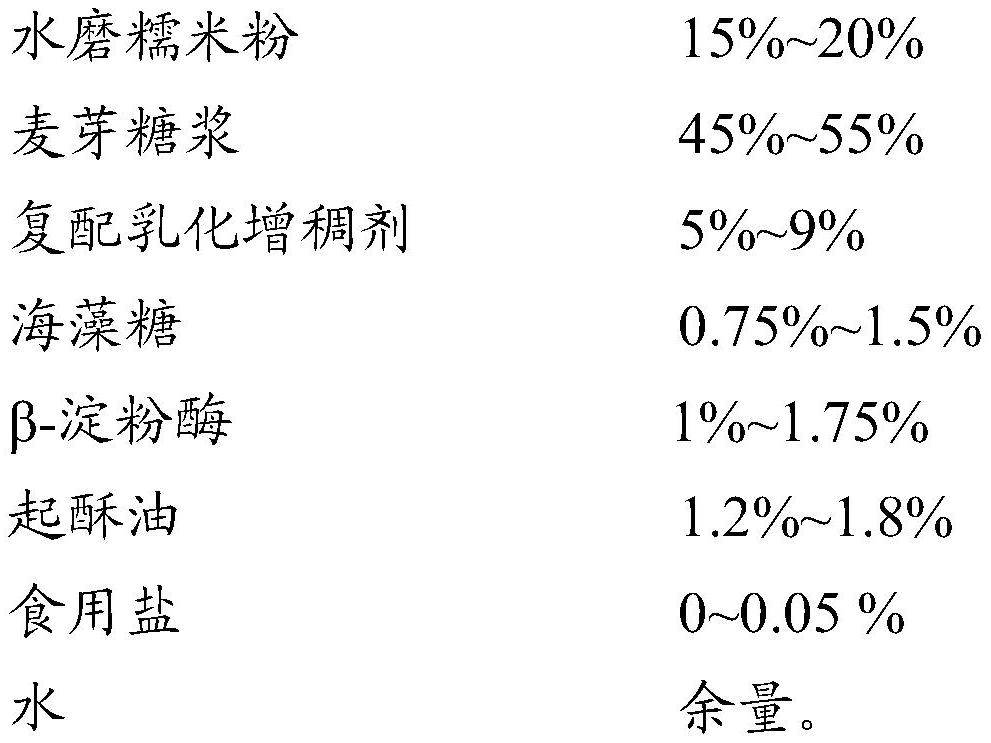

[0063] The present embodiment glutinous rice cake skin material (total weight 20kg):

[0064] Glutinous rice flour A (water mill, gelatinization temperature 59.92°C, aging degree 4.31) 3.00kg, maltose syrup (glucose equivalent value 80) 10.00kg, compound emulsification thickener 1.8kg, trehalose 0.15kg, β-amylase 0.20 kg, shortening 0.35kg, salt 0.005kg, drinking water 4.495kg.

[0065] The preparation method of the glutinous rice cake skin layer of the present embodiment is basically the same as that of the embodiment 1, the difference is: the salt is added after mixing with the dry materials before steaming; The amount of hot maltose syrup at 80±5℃.

[0066] According to the raw material formula of the glutinous rice cake skin layer provided by the present embodiment, through the above-mentioned production process, a glutinous rice cake skin layer with high transparency, Q elasticity, natural fragrance and anti-regeneration effect can be obtained.

Embodiment 3

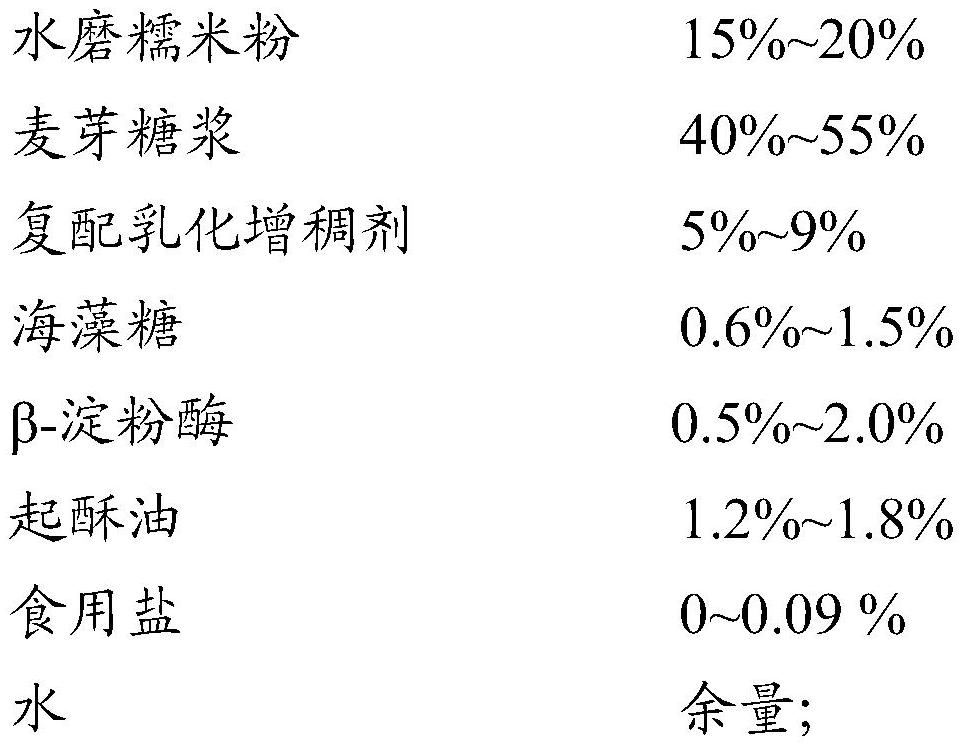

[0068] The present embodiment glutinous rice cake skin material (total weight 20kg):

[0069] Glutinous rice flour B (water mill, gelatinization temperature 59.48°C, aging degree 3.36) 3.50kg, maltose syrup (glucose equivalent value 70) 10.00kg, compound emulsification thickener 1.5kg, trehalose 0.25kg, β-amylase 0.20 kg, shortening 0.30kg, drinking water 4.25kg.

[0070] The preparation method of the glutinous rice cake skin layer of the present embodiment is basically the same as that of the embodiment 1, the difference is: the salt is added after mixing with the dry materials before steaming; The amount of hot maltose syrup at 80±5℃.

[0071] According to the raw material formula of the glutinous rice cake skin layer provided in this embodiment, through the above-mentioned production process, a kind of glutinous rice cake skin with good elasticity, natural aroma and anti-regeneration effect can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com