Monochromator crystal orientation method

A crystal orientation, monochromator technology, applied in instruments, measuring devices, working accessories, etc., can solve the problems of unusable, easily damaged electric arc swing table, and harsh working environment, and achieve the effect of getting rid of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

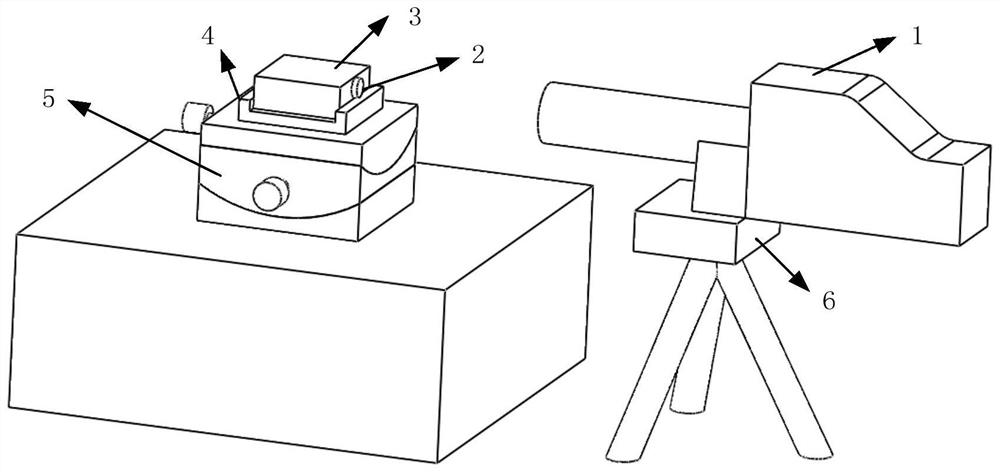

[0035] Below in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail.

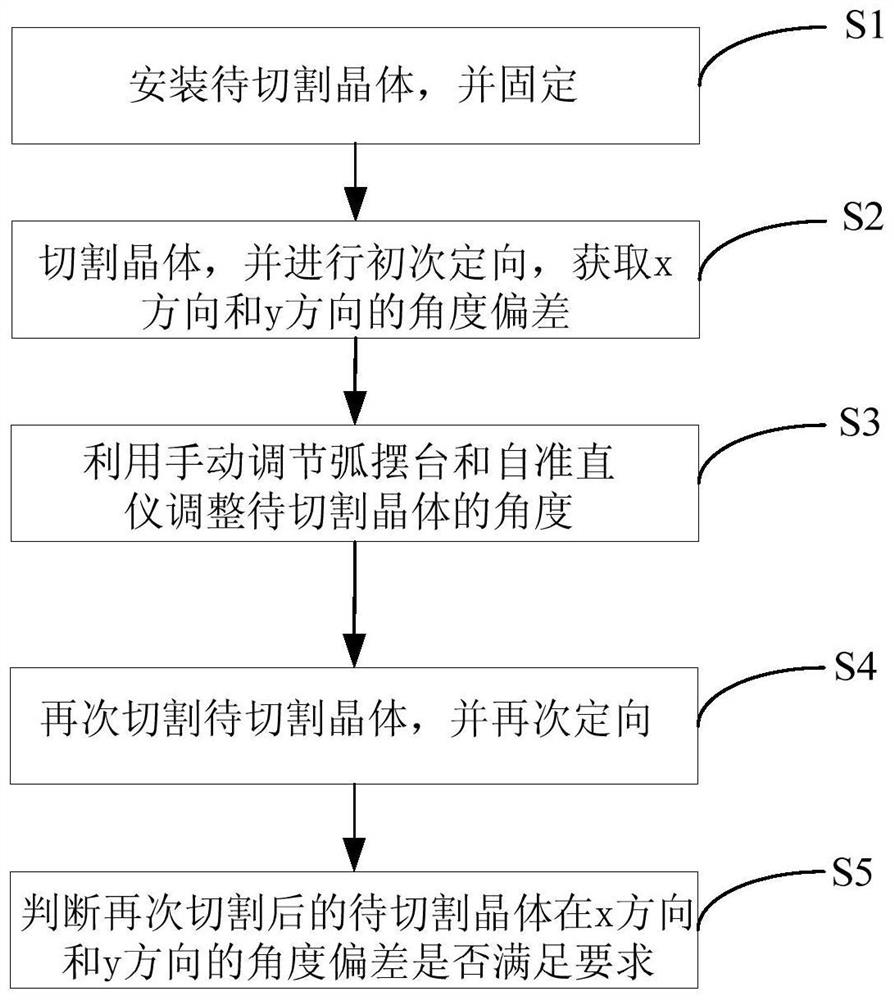

[0036] like figure 2 and image 3 As shown, the monochromator crystal orientation method provided by the present invention includes the following steps:

[0037] In step S1 , the crystal to be cut 3 is installed on the manually adjustable arc pendulum table 5 , and the crystal to be cut 3 is fixed by the crystal holder 4 . Specifically, step S1 includes:

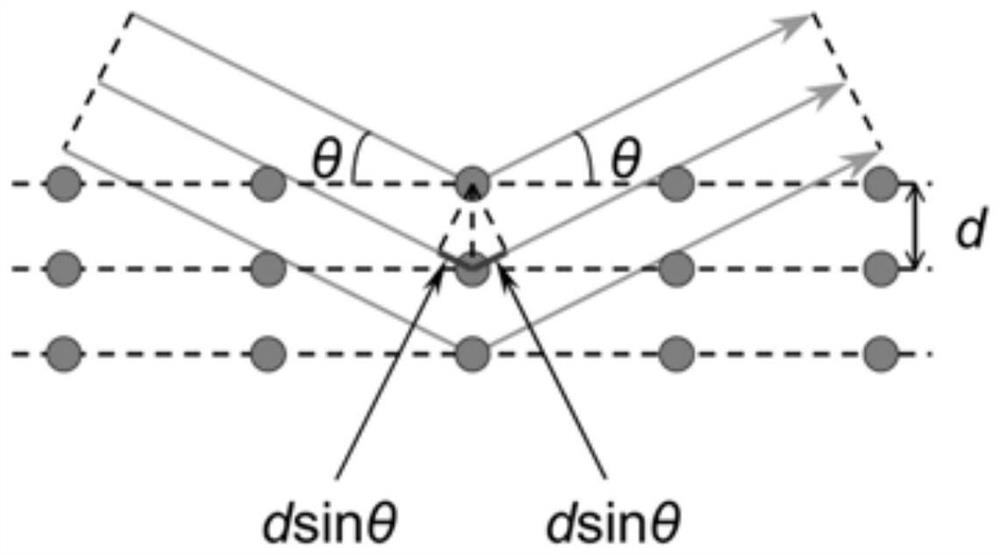

[0038] In step S11 , the intergranular angle θ between the required crystal orientation of the crystal 3 to be cut and the known crystal orientation is calculated by means of the included angle of the crystal system.

[0039] Taking a single crystal silicon crystal as an example, the known crystal orientation is usually the crystal orientation of the end face of the single crystal silicon rod. At present, the crystal orientation of the end face of the single crystal silicon rod i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com