3D printer with double light spots and light spot switching method thereof

A 3D printer and double-spot technology, applied in 3D object support structures, manufacturing tools, processing data acquisition/processing, etc., can solve the problems of slow spot size switching speed, reduced processing accuracy, low efficiency, etc., and achieve fast switching speed, Improve accuracy and implement high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

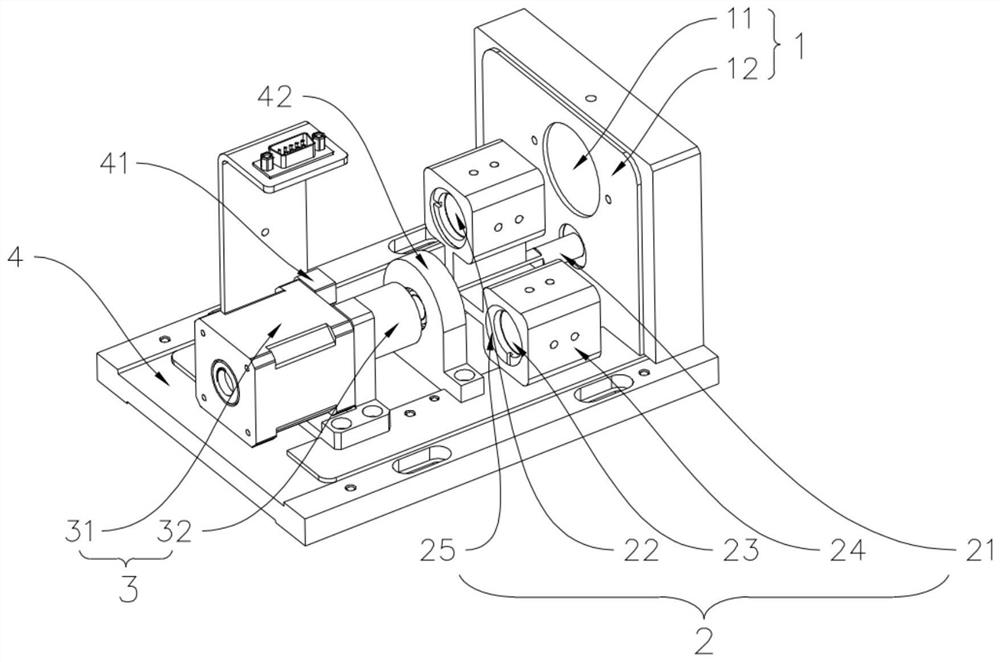

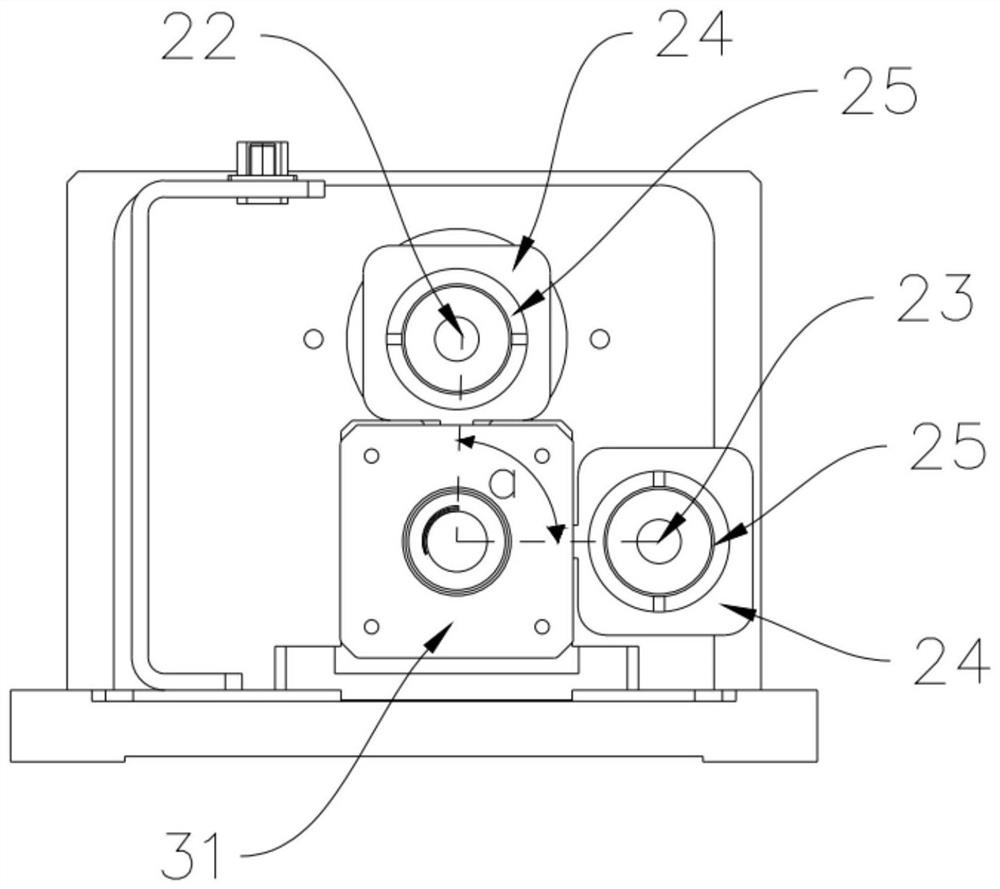

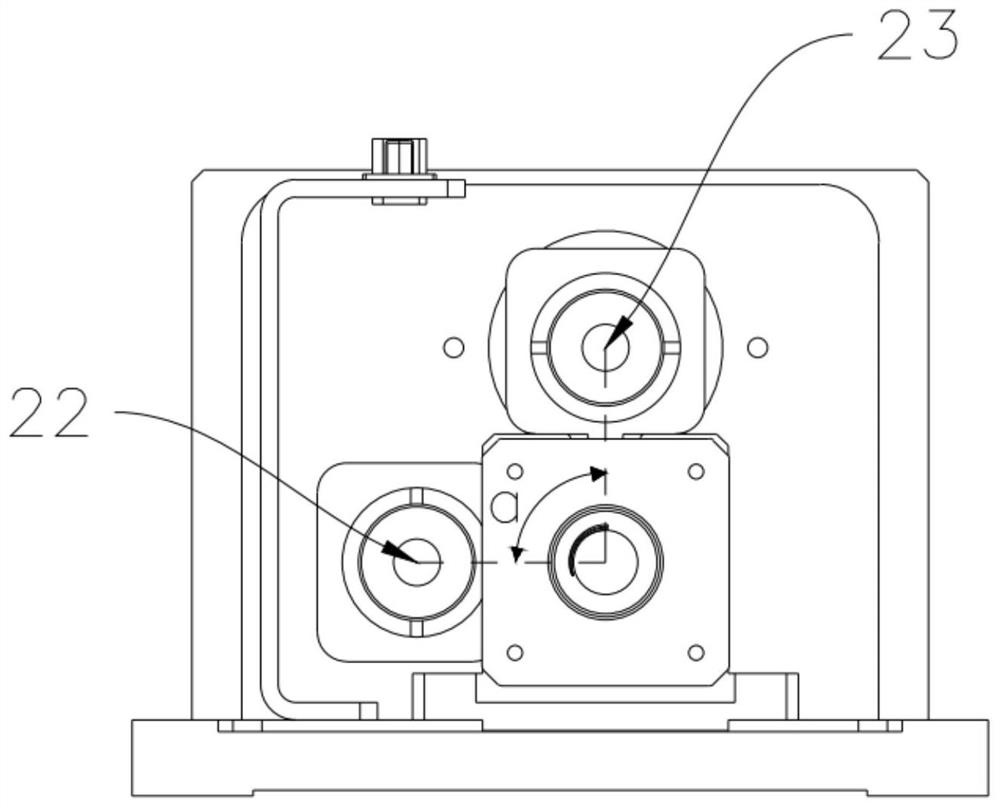

[0042] Please refer to Figure 1-5 , a 3D printer with double light spots, including a light spot adjustment mechanism arranged in the 3D printer, the light spot adjustment mechanism includes a stationary lens unit 1 and a movable lens unit 2 arranged oppositely, and a unit for driving the movable lens. Unit 2 rotates drive unit 3. The stationary lens unit 1 includes a fixed first optical lens 11 . The movable lens unit 2 includes a rotating shaft 21 and a second optical lens 22 and a third optical lens 23 fixedly arranged in the circumferential direction of the rotating shaft 21 . The first optical lens 11 , the second optical lens 22 and the The third optical lenses 23 are arranged at intervals along the axial direction of the rotating shaft 21 . When the second optical lens 22 and the first optical lens 11 are coaxial, it is the first position, and the first position is the first spot size; the third optical lens 23 and the first optical lens 11 When it is coaxial, it is...

Embodiment 2

[0050] Please refer to Image 6 , a light spot switching method using the above-mentioned 3D printer with dual light spots, comprising the following steps:

[0051] S01, setting light spot parameters, respectively setting the distances between the second optical lens 22 and the third optical lens 23 and the first optical lens 11 according to the light spot parameters of the 3D printer;

[0052] S02 , adjust the spot size, and rotate the rotating shaft 21 according to the spot size required for printing, so that the second optical lens 22 or the third optical lens 23 is concentric with the first optical lens 11 .

[0053] The setting of the light spot parameters includes selecting different lens curvatures and lens focal lengths according to the light spot parameters of the 3D printer. That is, the distance parameter from the first optical lens 11 can be adjusted by selecting the second optical lens 22 and the third optical lens 23 with different lens curvatures and lens focal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap