Mordenite molecular sieve as well as preparation method and application thereof

A mordenite and molecular sieve technology, applied in the field of molecular sieves, can solve the problems of difficult aluminum distribution regulation, easy carbon deposition and deactivation, poor hydrothermal stability, etc., and achieves the effects of improving stability, simple process and facilitating large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] The molar proportions of each raw material and the crystallization conditions are shown in Table 1. First, 1.643g of sodium aluminate was added to 35g of deionized water, and then 1.617g of sodium hydroxide was added to it. After mixing evenly, 1g of tetramethylmethanediamine, 2g of cyclohexylamine, 40g of silica sol, and 0.25g of seed crystals were added. Continue stirring at room temperature until a homogeneous initial gel forms. The gel was put into a stainless steel reactor with a polytetrafluoroethylene lining, and the temperature was raised to 160 °C for crystallization for 30 h. The obtained solid product was centrifuged, washed with deionized water until neutral, and dried in air at 110 °C to obtain The original powder is recorded as sample 1#.

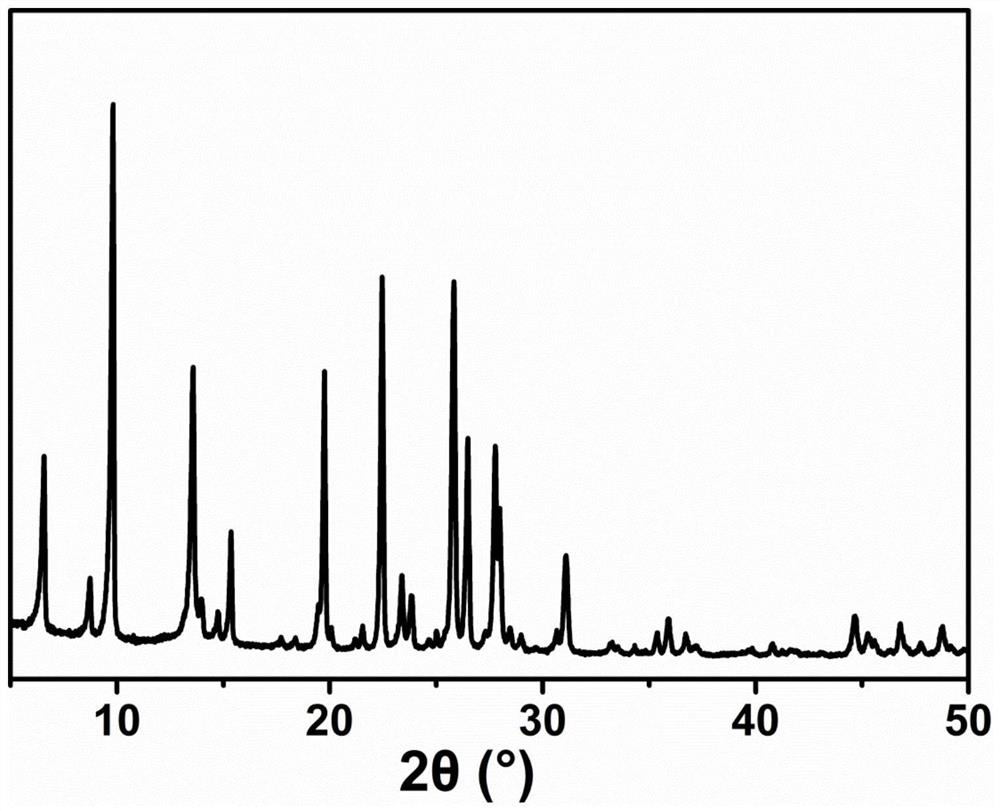

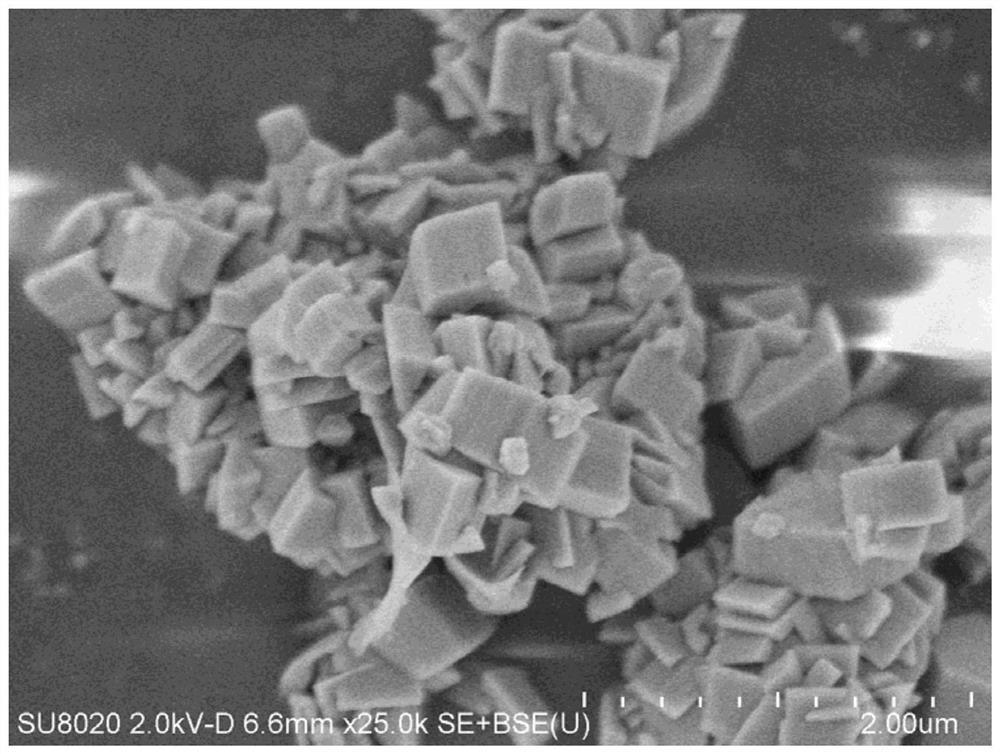

[0139] The product was subjected to XRD analysis, and the results showed that the synthesized product had the characteristics of MOR structure (see XRD pattern in figure 1 ). The elemental composition of the molecula...

Embodiment 2-20

[0142] The specific batching ratio and crystallization conditions are shown in Table 1, and the specific batching process is the same as that in Example 1.

[0143] The synthesized sample was analyzed by XRD, and the X-ray diffraction pattern of the product had figure 1 The characteristic is proved to be mordenite molecular sieve.

[0144] The phase element composition of the molecular sieve product was analyzed by XRF, and the silicon-aluminum ratio was listed in Table 1.

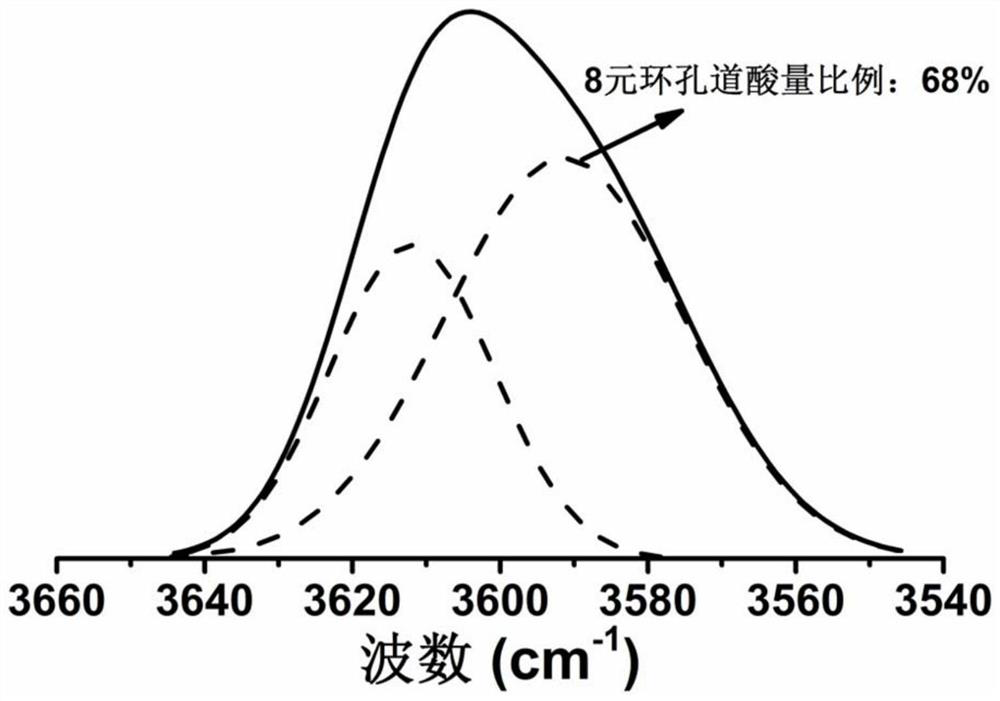

[0145] The hydrogen type infrared spectrum of the obtained sample was measured, and according to the literature (JACS, 2007, 129, 4919-4924), the 3610 cm -1 The nearby bridge hydroxyl groups were subjected to peak fitting, and the percentage of B acid in the total B acid in the 8-membered ring pore was obtained, which is listed in Table 1.

[0146] Table 1 Molecular sieve synthesis ingredients and crystallization conditions *

[0147]

[0148] Note*: Silicon source: a means silica sol; b means white ...

Embodiment 21

[0157] Except replacing sodium hydroxide with potassium hydroxide, other batching ratios and batching processes, and crystallization conditions are the same as those in Example 9. The product is subjected to XRD analysis, and the X-ray diffraction spectrum of the product has figure 1 The characteristic is proved to be mordenite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com