Delay gelatinizing composite plugging liquid and preparation method thereof

A plugging liquid and gelling technology, applied in the field of materials, can solve the problems of shortening pumpable time, early thickening, poor resistance to formation water dilution, etc., to overcome the contradiction between activator and retarder, and improve resistance to formation water The ability to disperse and the effect of improving the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

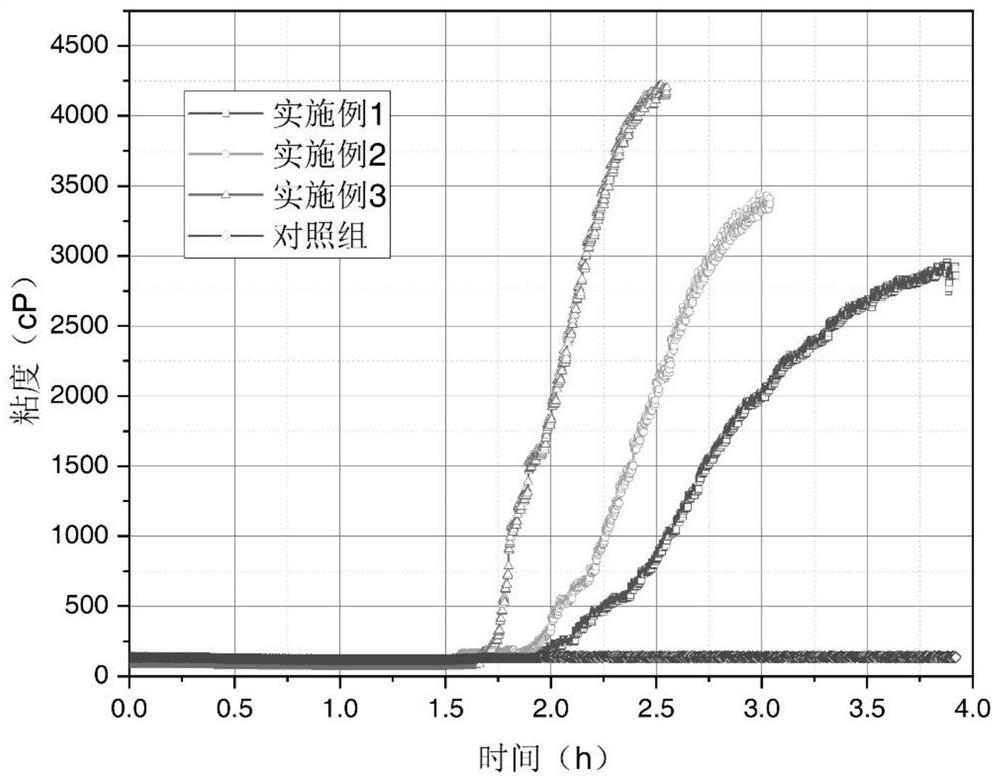

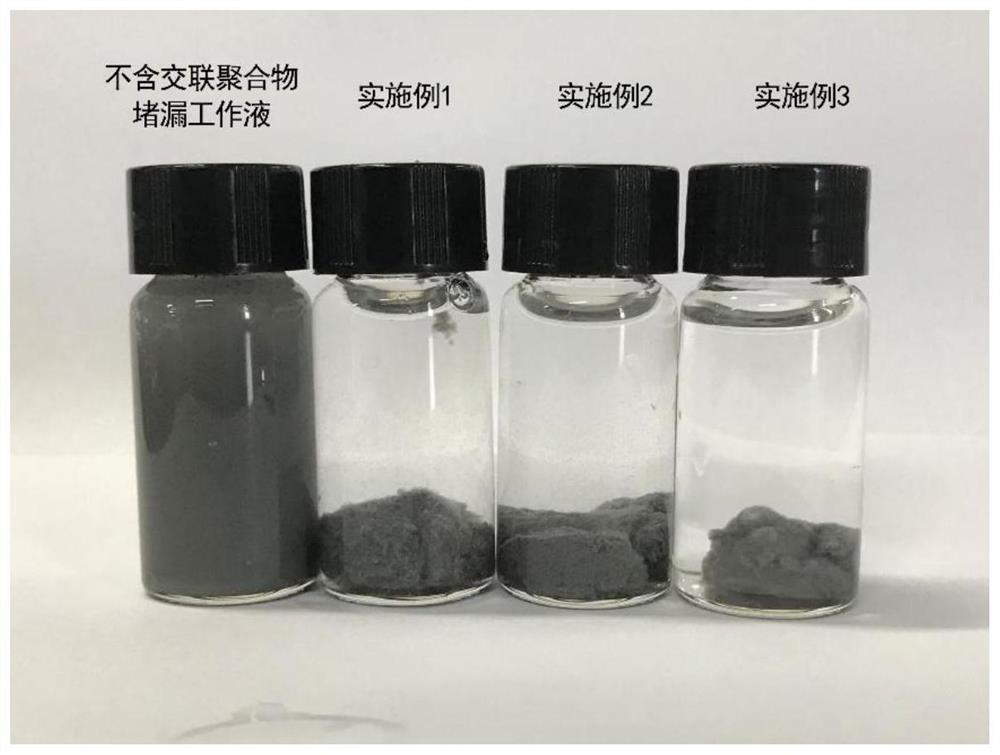

[0053] A time-delayed gel-forming composite leakage plugging fluid suitable for water-resistant dispersion of high-temperature fractured formations, the preparation method of which is as follows:

[0054] Add 5% polymer suspending agent PAM (molecular weight 3×10) in 100% fresh water 6 Da) and 0.5% polymer suspending agent CMC, after the polymer suspending agent is dissolved, continue to add 0.5% crosslinking agent PEI (molecular weight 2.5×10 4 Da), stir evenly, then add 70% of the main curing agent S95 blast furnace slag, 5% of the curing auxiliary agent metakaolin, 1% of the activator sodium silicate, 1% of the retarder sodium gluconate, at 800r Stir for 20 minutes at a speed of / min until the solid phase particles are uniformly dispersed, that is, a delayed gel-forming composite leakage plugging fluid suitable for water-resistant dispersion of high-temperature fractured formations of the present invention is prepared.

Embodiment 2

[0056] A time-delayed gel-forming composite leakage plugging fluid suitable for water-resistant dispersion of high-temperature fractured formations, the preparation method of which is as follows:

[0057] Add 0.75% delay agent ammonium chloride to 100% fresh water, after the delay agent dissolves, add 7.5% polymer suspending agent PAM (molecular weight 2×10 6 Da) and 0.5% polymer suspending agent xanthan gum, after the polymer suspending agent is dissolved, continue to add 1.5% cross-linking agent PEI (molecular weight 7×10 3 Da), stir evenly, then add 90% of the main curing agent S105 blast furnace slag, 10% of the curing auxiliary agent metakaolin, 20% of the density regulator barite powder, 2% of the activator sodium silicate, 1.5% The retarder citric acid was mixed at a speed of 800 r / min for 20 minutes until the solid phase particles were uniformly dispersed, that is, a delayed gel-forming composite leakage plugging liquid suitable for water-resistant dispersion of high t...

Embodiment 3

[0059] A time-delayed gel-forming composite leakage plugging fluid suitable for water-resistant dispersion of high-temperature fractured formations, the preparation method of which is as follows:

[0060] Add 0.3% sodium chloride, a time delay agent, to 100% fresh water. After the time delay agent dissolves, add 10% polymer suspending agents 2-acrylamide-2-methylpropanesulfonic acid (AMPS), styrene sulfonic acid Copolymer of sodium (SSS) and acrylamide (AM), 1.5% polymer suspending agent xanthan gum, after the polymer suspending agent is dissolved, continue to add 2.5% crosslinking agent PEI (molecular weight 5×10 4 Da), stir evenly, then add 70% of the main curing agent S95 blast furnace slag, 15% of the curing auxiliary agent fly ash, 1.5% of the activator sodium silicate, and stir at a speed of 800r / min for 20min, until the solidification The phase particles are uniformly dispersed, that is, a time-lapse gel-forming composite leakage plugging liquid suitable for water-resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com