Method for synthesizing low-temperature stable intermediate phase

A low-temperature stable, mesophase technology, applied in the field of metal materials, can solve the problems of slow formation kinetics, unobservable, difficult preparation, etc., to achieve simple preparation process, avoid the risk of oxidation and gas inclusion introduction, high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1

[0034] Raw materials in this example: manganese powder, aluminum powder.

[0035] The mesophase synthesis process includes the following steps:

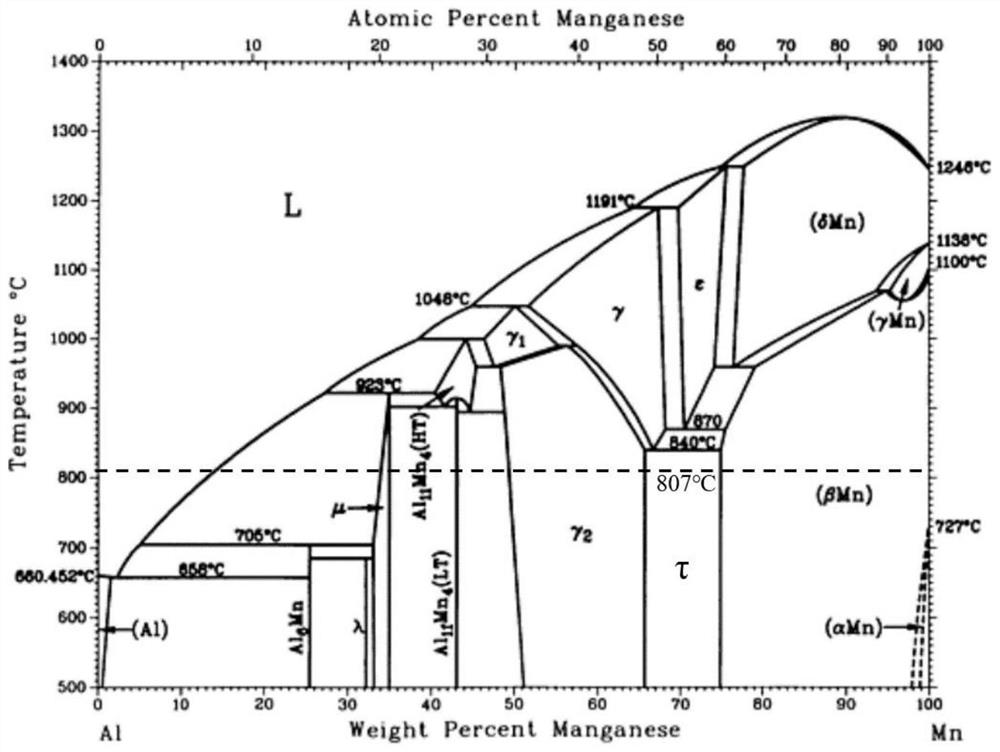

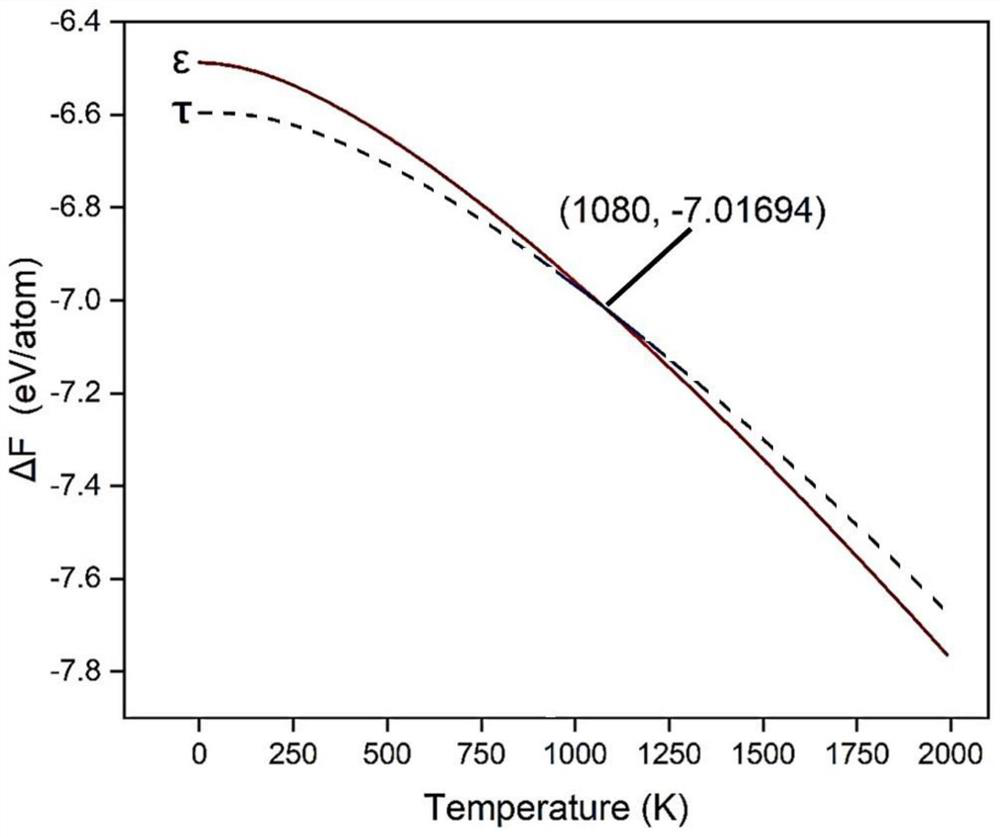

[0036] (1) First use the first principles to calculate as figure 2 As shown, the Ts temperature of the obtained τ phase is 1080K (807°C), and the mass ratio of the two alloy elements manganese / aluminum is 7:3.

[0037] (2) According to the mass ratio of each alloy element, weigh an appropriate amount of manganese powder and aluminum powder, mix and compact to form preform 3 .

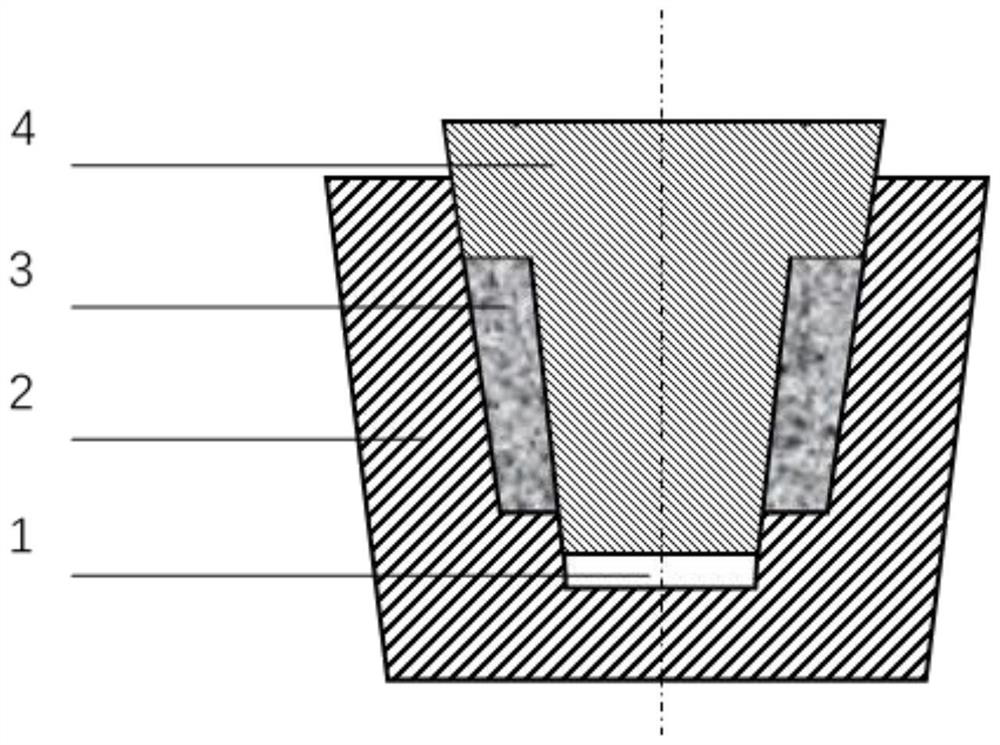

[0038] (3) Place the preform 3 on the figure 1 In the lower mold 2 shown, the lower mold 2 can be rotated, there is a gap 1 between the upper mold 2 and the lower mold 4, the upper mold 4 applies the hydrostatic pressure of 4GPa to it to compact the mixed material, and the lower mold 2 rotates 30 circles to make The compacted preform 3 undergoes shear plastic deformation at room temperature, and realizes micro-mixing between alloy eleme...

Embodiment 2

[0041] Example 2

[0042] Raw materials in this example: manganese powder, aluminum block.

[0043] In this embodiment, the preform 3 is prepared by digging holes in the aluminum block and filling the manganese powder. The other procedures are the same as in Example 1.

Embodiment 3

[0045] Example 3

[0046] Raw materials in this example: iron powder, vanadium powder.

[0047] The mesophase synthesis process includes the following steps:

[0048] (1) First, first-principles calculations were used to obtain the disorder-order transition temperature of iron-vanadium alloys with equal atomic ratio, that is, the Ts of the mesophase ordered solid solution FeV-P4 / nmm was 1350K (1077°C); Figure 7 shown.

[0049] (2) According to the atomic ratio of alloying elements in the mesophase ordered solid solution FeV-P4 / nmm, an appropriate amount of iron powder and vanadium powder are weighed, mixed and compacted to form a preform 3 .

[0050] (3) Place the preform 3 on the figure 1 In the lower mold 2 shown, the upper mold 4 applies a hydrostatic pressure of 6GPa to compress the mixed material, and the lower mold 2 rotates 50 circles, so that the compacted preform 3 undergoes shear plastic deformation at room temperature to realize the alloying elements. The inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com