Three-layer multi-beam luneberg lens antenna

A Lumber lens antenna and multi-beam technology, which is applied in the direction of antenna, antenna parts, antenna grounding switch structure connection, etc., can solve the problems of high processing cost, high cost, heavy weight, etc., and achieve improved antenna gain and low processing difficulty , the effect of strengthening the practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0039] see Figure 1-10 As shown, the specific embodiments provided by the present invention are as follows:

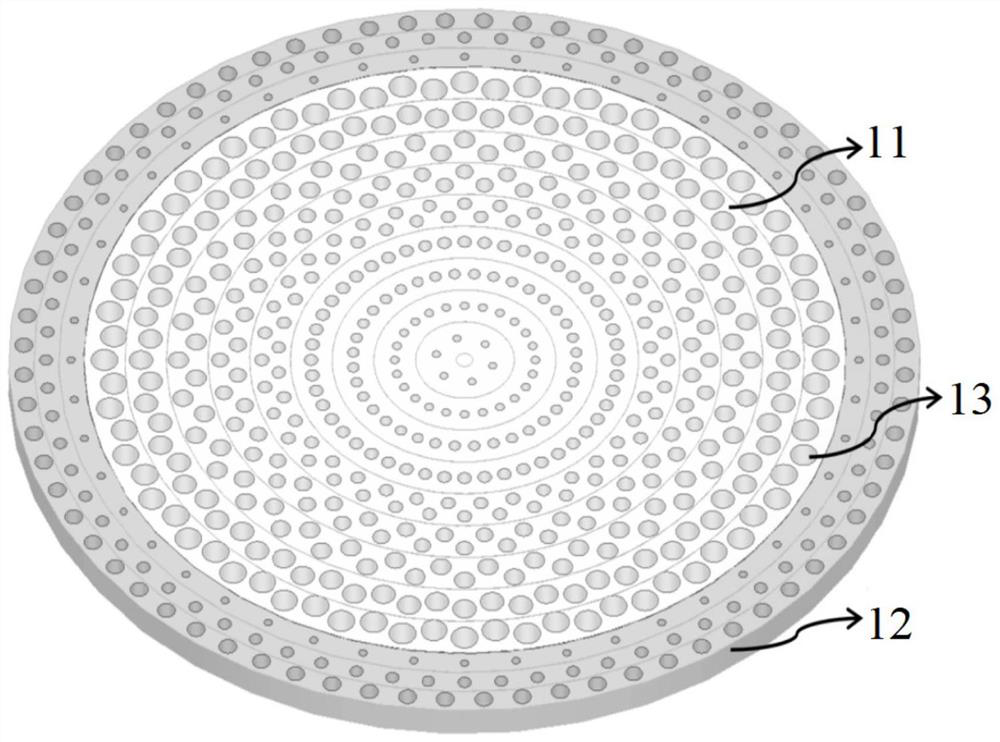

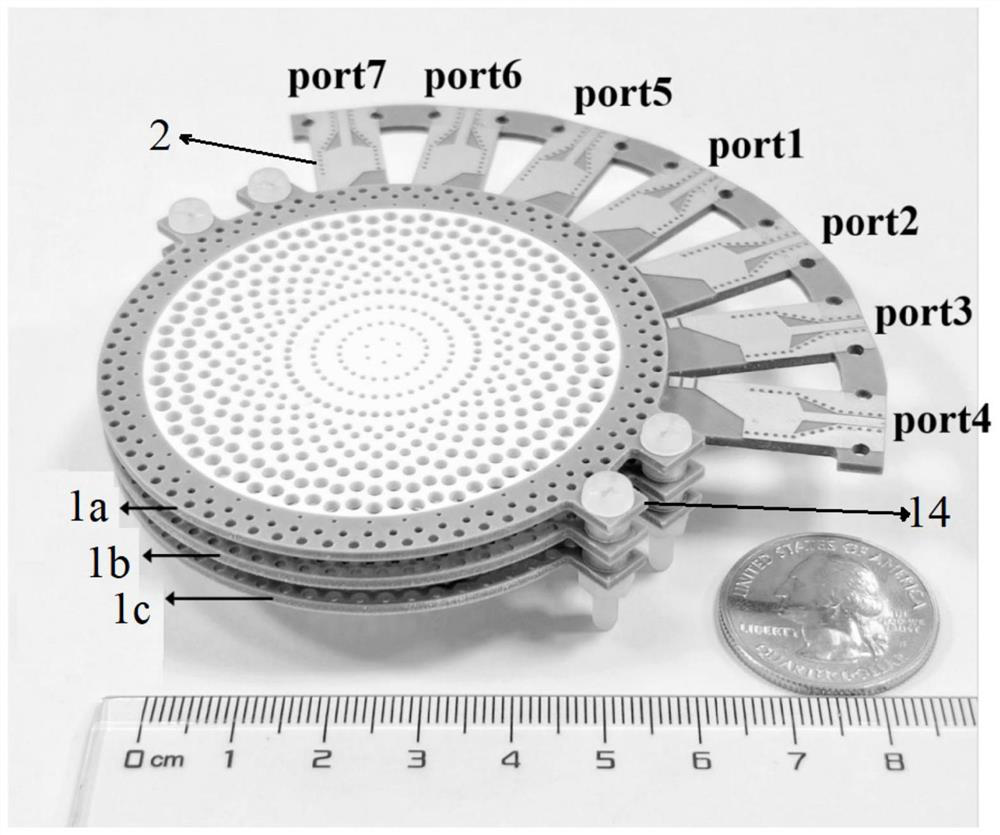

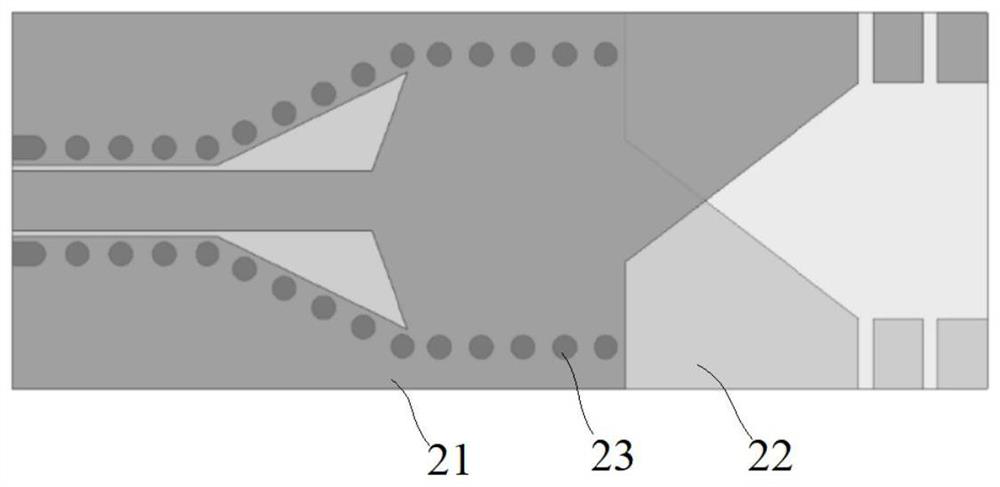

[0040] combine Figure 1-2 As shown in the figure, this embodiment provides a three-layer multi-beam Lunberg lens antenna, which includes a top dielectric substrate 1a, an intermediate layer dielectric substrate 1b and a bottom dielectric substrate 1c with the same structure. The three-layer dielectric substrate is in a direction perpendicular to the dielectric substrate. A parallel and spaced arrangement is formed; it can be understood that, in practical applications, in order to facilitate the fixing of each layer of dielectric substrates, at least one fixing part can be provided at the edge of each layer of the dielectric substrate, and the fixing part can be connected to the corresponding dielectric substrate. The substrates are connected as a whole, for example, as figure 2 As shown in the figure, the fixing part is set as a fixing ear 14 extending from one si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com