Plant minced meat, preparation method thereof and plant meat product

A technology of meat products and plants, which is applied in the direction of plant protein processing, food science, protein food ingredients, etc., can solve the problems of not being able to completely eliminate animal-derived antibiotics and lack of chewiness, so as to eliminate animal-derived antibiotics, improve nutritional value, and reduce Effect of Cholesterol Levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

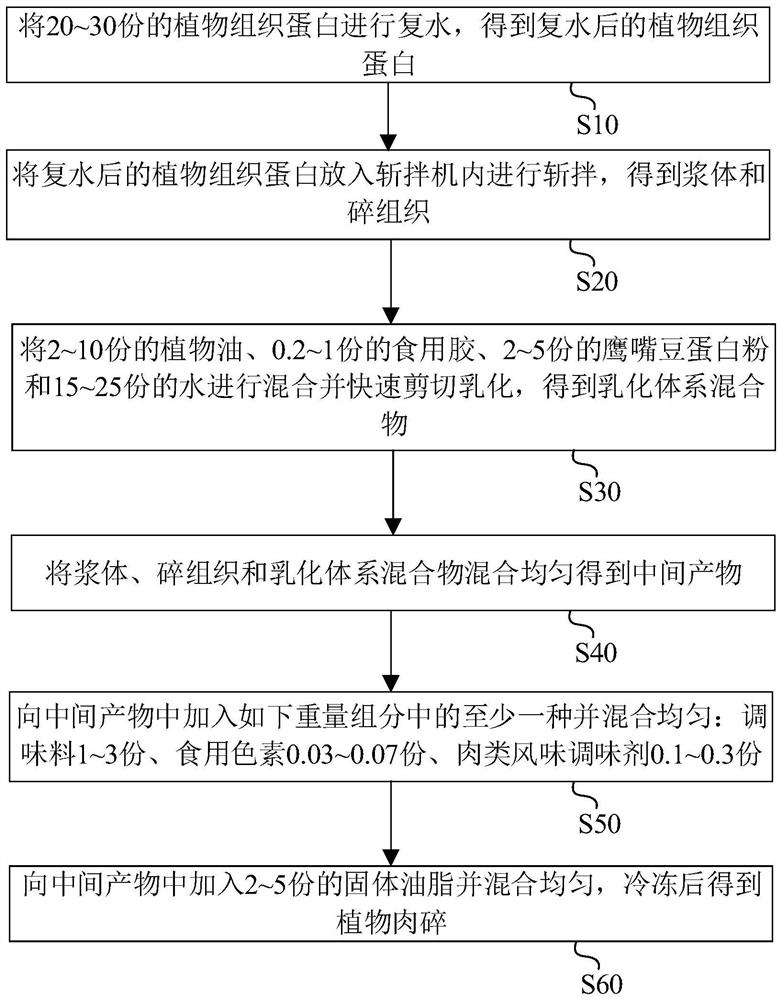

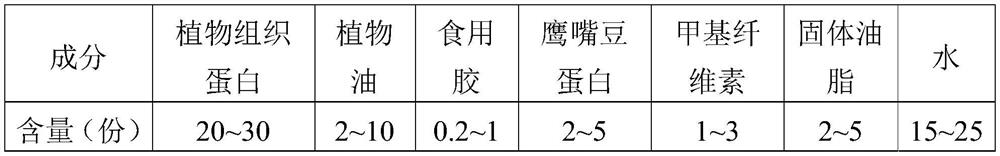

[0049] refer to figure 1 , the application also provides a kind of preparation method of vegetable minced meat, comprising the steps:

[0050] In step S10, 20-30 parts of plant tissue protein are rehydrated to obtain rehydrated plant tissue protein, and the weight ratio of plant tissue protein before and after rehydration is controlled to be (0.8-1.2): (2-4).

[0051] Step S20, putting the rehydrated plant tissue protein into a chopping machine for chopping to obtain a slurry and crushed tissue. Specifically: dividing the rehydrated plant tissue protein into two parts and separately chopping to form the slurry and the crushed tissue, so that the slurry obtained by chopping is free of particulate matter, so that the particle diameter of the crushed tissue obtained by chopping is 4mm-8mm, and the weight ratio of the slurry obtained by chopping and the obtained broken tissue is controlled to be (0.8-1.2): (0.5-1.5). Among them, the chopping machine can be equipment such as a co...

Embodiment 1

[0057] The preparation process of the vegetable minced meat of the present embodiment is as follows:

[0058] Step 1: rehydrate 20 parts of plant tissue protein to obtain rehydrated plant tissue protein. Wherein, the relative weight parts of the formula of plant tissue protein are prepared by mixing, extruding and puffing according to 30 parts of hemp seed protein powder, 20 parts of gluten powder, and 5 parts of starch, and are prepared by drying.

[0059] Step 2: Divide the rehydrated plant tissue protein into two parts and put them into a food processor respectively for chopping and stirring to obtain slurry and broken tissue. The slurry obtained after chopping has no particles, the particle diameter of the broken tissue is 4 mm, and the weight ratio of the slurry obtained by chopping to the obtained broken tissue is 1.2:0.5

[0060] Step 3: Mix 3 parts of vegetable oil, 0.5 part of edible gum, 3 parts of chickpea protein powder and 20 parts of water, and rapidly shear and...

Embodiment 2

[0064] The preparation process of the vegetable minced meat of the present embodiment is as follows:

[0065] Step 1: rehydrate 30 parts of plant tissue protein to obtain rehydrated plant tissue protein. Wherein, the relative weight parts of the formula of plant tissue protein are prepared by mixing, extruding and puffing according to 45 parts of hemp seed protein powder, 30 parts of gluten powder, and 18 parts of starch, and are prepared by drying.

[0066] Step 2: Divide the rehydrated plant tissue protein into two parts and put them into a food processor respectively for chopping and stirring to obtain slurry and broken tissue. The slurry obtained after chopping has no particles, the particle diameter of the broken tissue is 4 mm, and the weight ratio of the slurry obtained by chopping to the obtained broken tissue is 0.8:1.5

[0067] Step 3: Mix 6 parts of vegetable oil, 0.8 part of edible gum, 3.3 parts of chickpea protein powder and 22 parts of water, and rapidly shear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com