Preparation method and application of high-purity cadmium antimonide

A cadmium antimonide, high-purity technology, applied in chemical instruments and methods, antimony compounds, inorganic chemistry, etc., can solve the problems that CdSb cannot approach the stoichiometric ratio, the influence of device performance, and the purity is not high, so as to reduce the residual antimony element, The effect of reducing the content of free cadmium and the simple and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

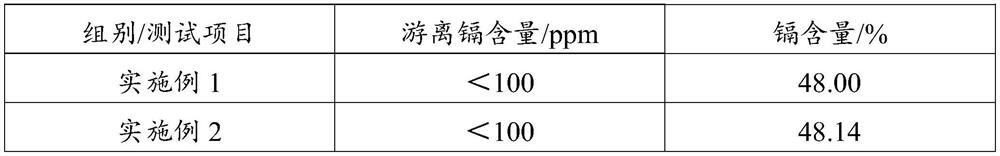

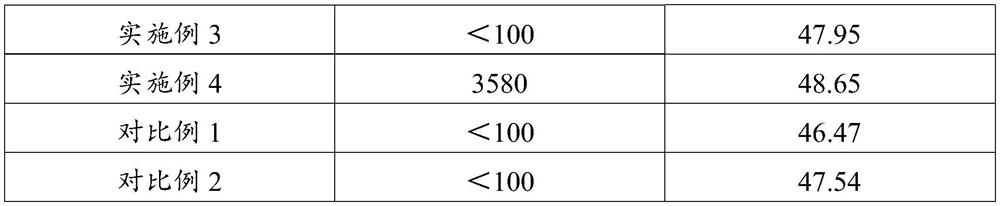

Embodiment 1

[0029] As an embodiment of the method of preparing high-purity cadmium antimonide of the present invention, comprising the following embodiment steps: (1) the cadmium particles and antimony masseurage 1.1: 1 ingredients into the graphite boat, wherein the antimony block is placed in the lower layer, cadmium particles in the upper layer; (2) the above materials are loaded into a horizontal tubular heating furnace, into an inert gas, the gas flow rate is 10L / min; After the inert gas is passed in for 30min, heating begins, the first insulation stage is heated from room temperature to 8 °C / min to 420 °C insulation for 50min, the second insulation stage is then heated to 10 °C / min, heated to 600 °C for 2h, and then the third insulation stage is heated at 10 °C / min to 680 °C for 4h, and cooled with the furnace to obtain high-purity cadmium antimonide.

Embodiment 2

[0031]As an embodiment of a method for preparing high-purity cadmium antimonide of the present invention, comprising the following embodiment steps: (1) the cadmium particles and antimony block massage Erbi 1.2: 1 ingredients into a graphite boat, wherein the antimony block is placed in the lower layer, cadmium particles in the upper layer; (2) the above material is loaded into a horizontal tubular heating furnace, into an inert gas, the gas flow rate is 8L / min; After the inert gas is introduced for 30min, heating begins, the first insulation stage is heated from room temperature to 10 °C / min to 350 °C, insulation is 30min, the second insulation stage is then heated to 5 °C / min, heated to 500 °C insulation for 1h, and then the third insulation stage is heated at 5 °C / min to 650 °C for 5h, and cooled down with the furnace to obtain high-purity cadmium antimonide.

Embodiment 3

[0033] As an embodiment of the method of preparing high-purity cadmium antimonide of the present invention, specifically comprising the following embodiment steps: (1) the cadmium particles and antimony block massage Erbi 1.15: 1 ingredients into the graphite boat, wherein the antimony block is placed in the lower layer, the cadmium particles in the upper layer; (2) the above material is loaded into a horizontal tubular heating furnace, into an inert gas, the gas flow rate is 3L / min, after the inert gas is passed in for 30min, start heating, the first thermal insulation stage from room temperature to 5 ° C / min heating to 380 ° C, heat preservation 60min, The second insulation stage is then heated to 560 °C for 3h at 8 °C / min, and then the third insulation stage is heated to 8 °C / min to 700 °C for 3h, and cooled down with the furnace to obtain high-purity cadmium antimonide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com