Wastewater treatment method

A waste water treatment and waste water technology, applied in natural water body treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing investment cost and operating cost, and uneconomical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

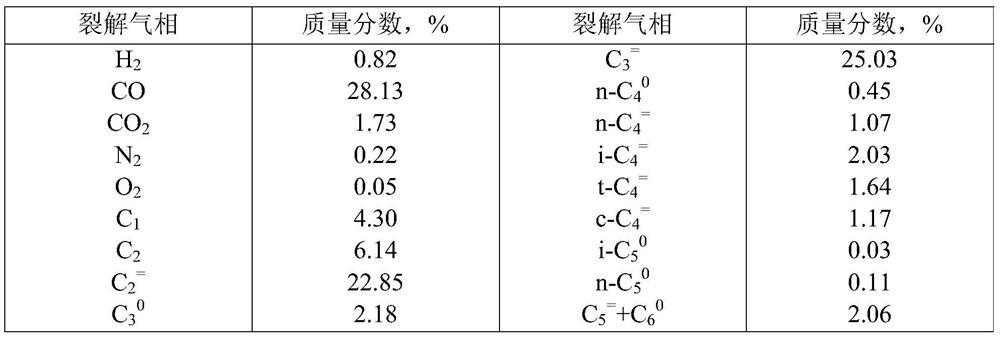

Embodiment 1

[0025] Catalytic cracking test was carried out in the fluidized-bed reactor, and the waste water obtained by mixing the waste water after the propylene preparation propylene oxide device to extract propylene glycol methyl ether and the alcohol-containing waste water obtained (referred to as "influent water" for short) contained organic matter, and its organic matter content was as shown in the table 1) is added from the inlet of the terminator in the middle of the fluidized bed reactor, and the wastewater containing organic matter and the raw material oil (density at 20 ° C is 0.92 g cm -3 , the feed ratio of distillation range IBP / EBP is 35-500 ℃) is 4.5: 100, the catalyst is the catalyst (wherein the content of alumina is 47 wt. %, the content of silicon oxide is 49% by weight, the content of rare earth oxide is 3% by weight), the weight ratio of the amount of catalyst to the raw oil is 5.3:100, and the conditions of catalytic cracking include: the reaction temperature is 510...

Embodiment 2

[0036]The catalytic cracking test was carried out in the fluidized bed reactor, and the wastewater containing organic matter (the composition is shown in Table 1) obtained by mixing the wastewater after the propylene production propylene oxide unit did not extract propylene glycol methyl ether and the alcohol-containing wastewater (the composition is shown in Table 1) was removed from the fluidized bed. The terminator inlet in the middle of the reactor is added, and the feed ratio of the described organic-containing waste water and feedstock oil (with Example 1) is 4:100, and the catalyzer is the trade mark of CGP- The catalyst of C (in which the content of alumina is 51% by weight, the content of silicon oxide is 47% by weight, and the content of rare earth oxide is 1% by weight), the weight ratio of the amount of the catalyst to the raw oil is 5:100, and the catalytic cracking The conditions included: the reaction temperature was 530 °C, the reaction pressure was 0.36 MPa, an...

Embodiment 3

[0040] The catalytic cracking test was carried out in the fluidized bed reactor, and the wastewater containing organic matter (the composition is shown in Table 1) obtained by mixing the wastewater after the propylene production propylene oxide unit did not extract propylene glycol methyl ether and the alcohol-containing wastewater (the composition is shown in Table 1) was removed from the fluidized bed. The terminator inlet at the bottom of the reactor adds, and the feed ratio of the described organic-containing waste water and feedstock oil (with Example 1) is 5.6:100, and the catalyzer is that the trade name of the commercial product from Sinopec Catalyst Company Changling Branch is CDOS. Catalyst (wherein the content of alumina is 50% by weight, the content of silicon oxide is 44% by weight, and the content of rare earth oxide is 5% by weight), the weight ratio of the amount of catalyst to the raw oil is 6:100, and the conditions of catalytic cracking Including: the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com