Air circulation high-salinity wastewater desalination treatment system

A high-salt wastewater and treatment system technology, applied in water/sewage treatment, water/sludge/sewage treatment, general water supply conservation, etc., can solve the problem of low energy utilization rate, achieve low type and concentration requirements, and reduce consumption , The effect of reducing the dependence on high-grade electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

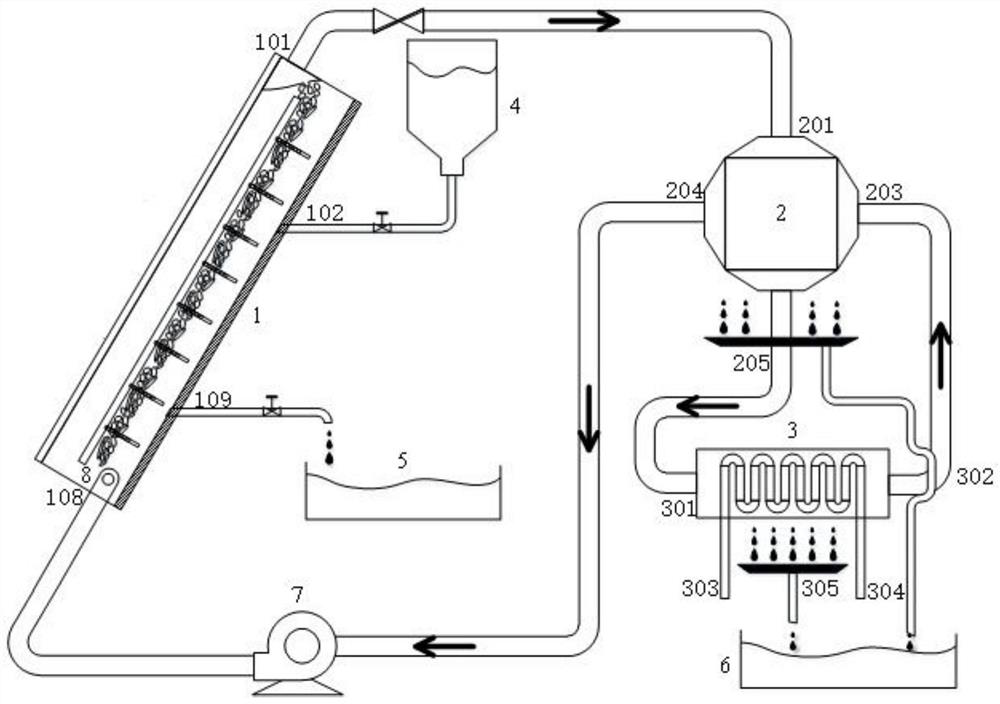

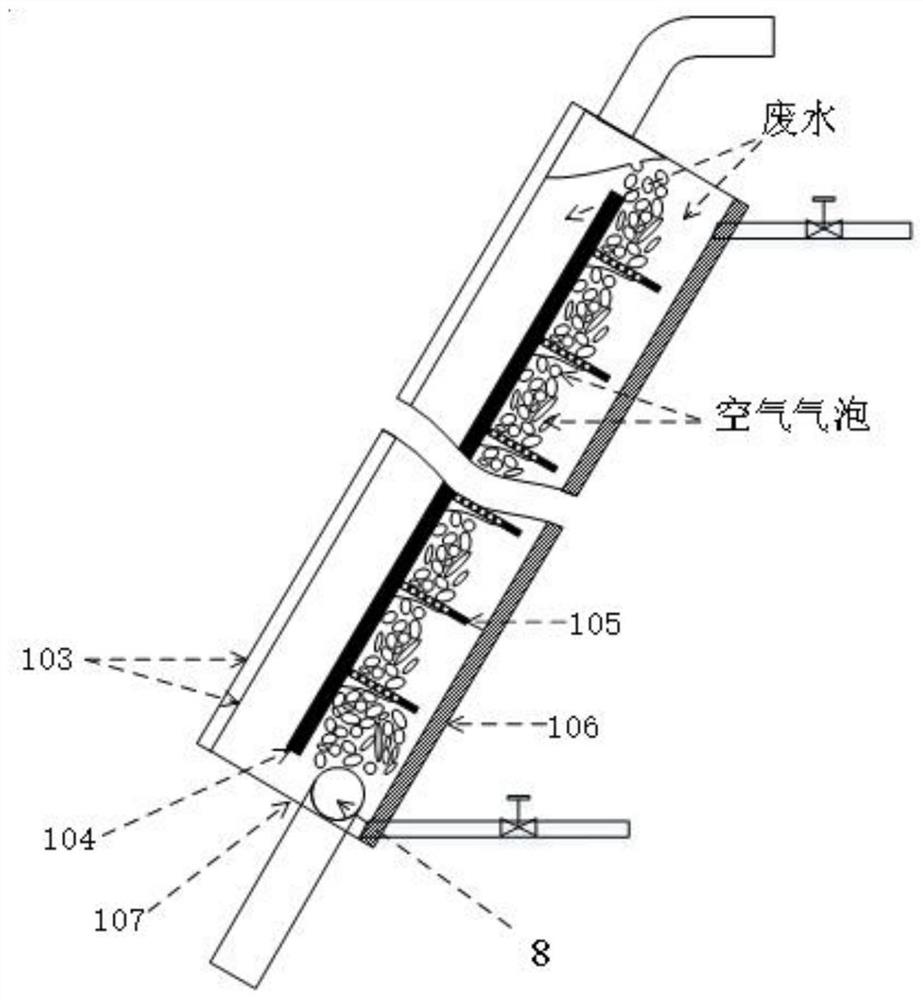

[0023] as Figure 1 As shown, an air circulation high-salt wastewater desalination treatment system, comprising: solar integrated collector - evaporator 1, air recuperator 2, water cooler 3, waste liquid rehydration tank 4, concentrated waste liquid recovery tank 5, condensate recovery tank 6, air pump 7, bubbler 8, butterfly damper 9.

[0024]The outlet of the air pump 7 is connected to the bubbler 8, and the outlet of the bubble 8 is located at the bottom of the solar integrated collector - evaporator 1; Solar integrated collector - the air outlet 101 at the top of the evaporator 101 is connected to the hot end inlet 201 of the air recuperator 201 through the butterfly damper 9, the hot end outlet of the air recuperator 202 is connected to the air inlet 301 of the water cooler 3, the air outlet of the water cooler 302 is connected to the cold end inlet of the air recuperator 203, the cold end outlet of the air recuperator 204 is connected to the air inlet of the air pump 7.

[00...

Embodiment 2

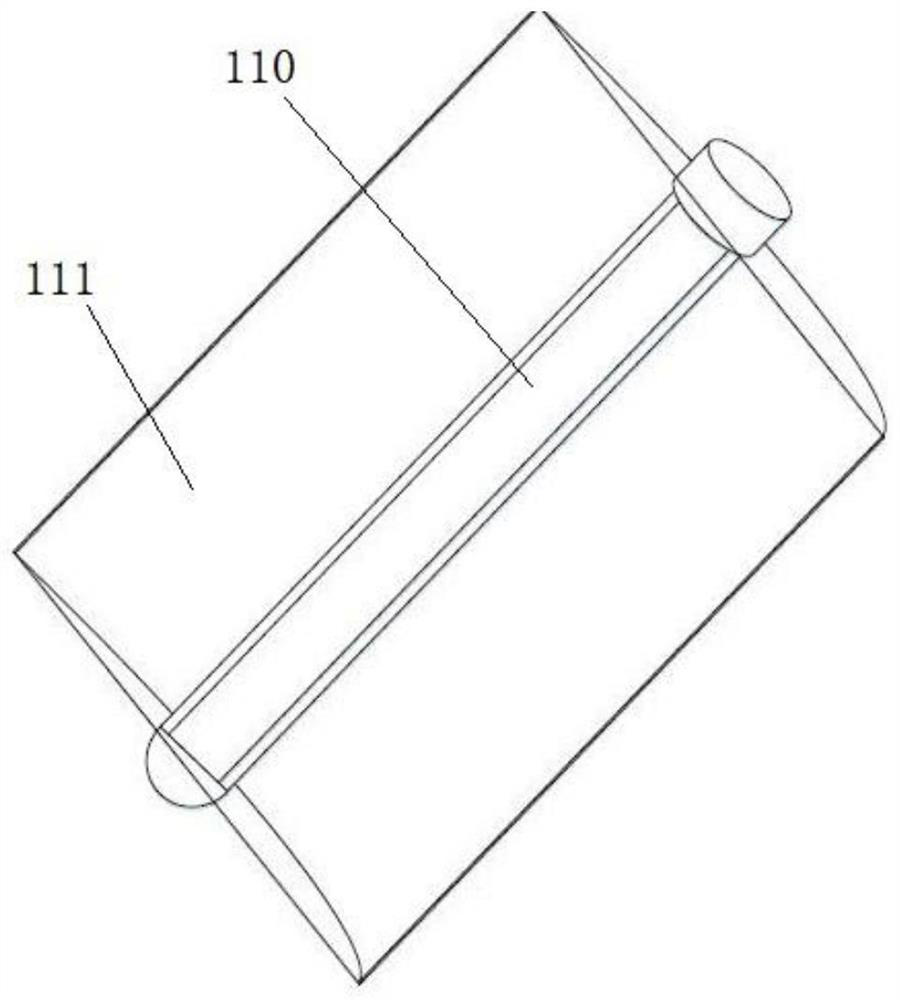

[0044] The difference from Example 1 is that the present embodiment provides another specific implementation structure of the solar integrated collector - evaporator 1. as Figure 3 As shown, the solar integrated collector - evaporator 1 includes a vacuum tube 110, a reflective condenser 111. as Figure 4As shown, the bottom end of the inclined vacuum tube 110 is closed, and the top opening of the vacuum tube 110 is connected to the air header 113. Vacuum tube 110 is provided with a number of bubbling regeneration plates 112 from bottom to top intervals, bubbling regeneration plates 112 are fixed by the support strip 114 within the vacuum tube 110, the bubbling regeneration plate 112 is densely covered with through holes, the diameter of the upper half of the through holes is less than the diameter of the lower half of the through holes. The vacuum tube 110 is connected to the butterfly damper 9 through the air header 113. The bubbler 8 is inserted from the top opening of the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com