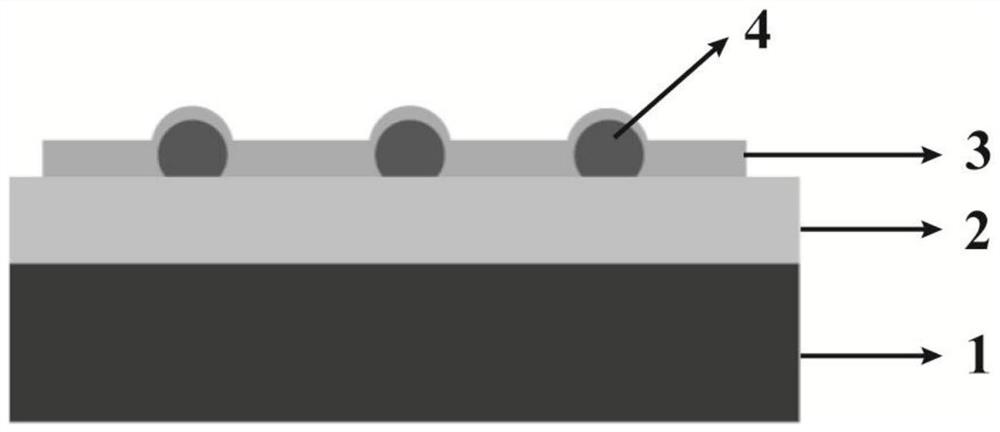

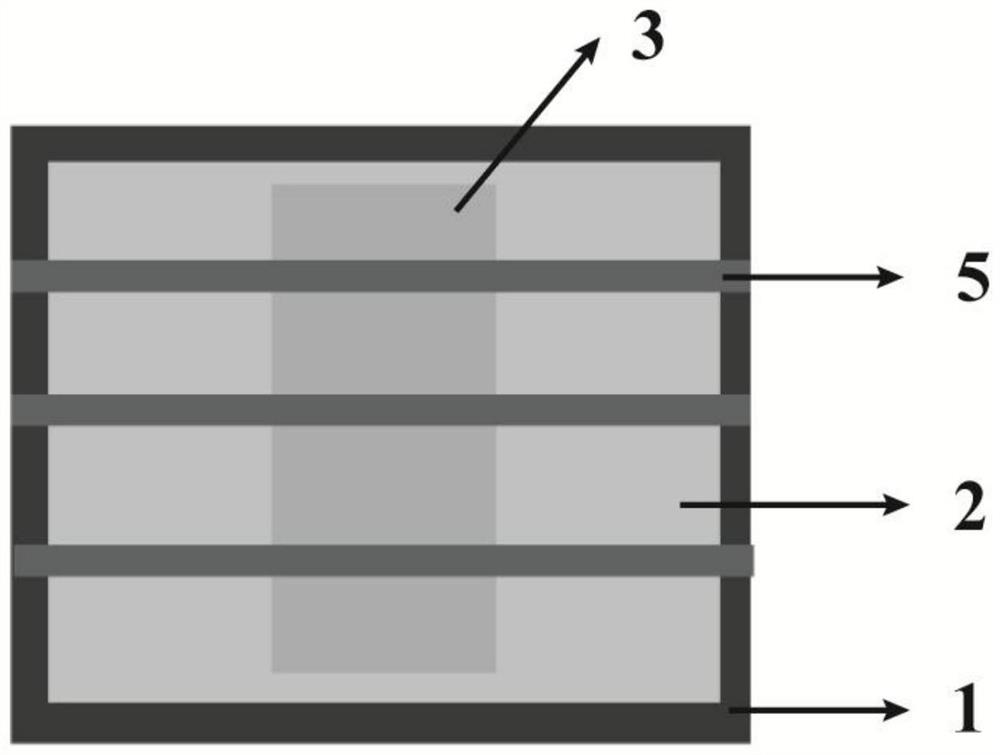

Preparation method of artificial synaptic device with nano channel

A synapse device, artificial technology, applied in the direction of replication/marking method, semiconductor/solid-state device manufacturing, semiconductor device, etc., can solve the problems of size limitation, energy consumption reduction of artificial synapse device, etc., and achieve the solution of size limitation, low power The effect of low consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

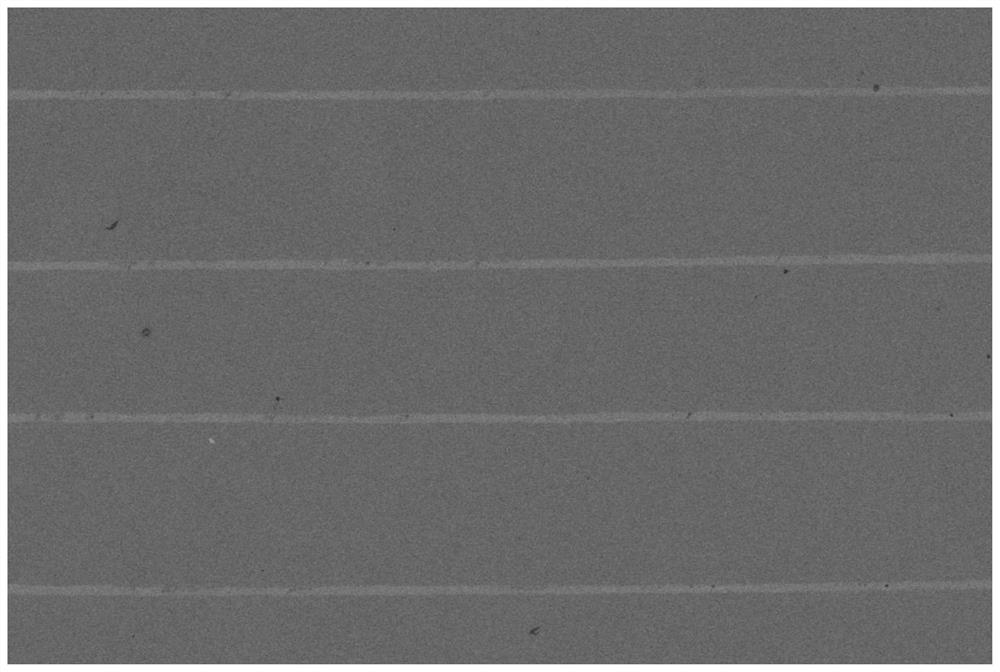

Examples

Embodiment 1

[0029] (1) 2.0×2.0cm 2 Si / SiO 2 The substrate was placed in an acetone solution for ultrasonic cleaning for 15 min, then placed in an isopropanol (IPA) solution for ultrasonic cleaning for 15 min, then the IPA was heated to boiling, the surface of the substrate was fumigated with IPA hot steam for 1 minute, and then N 2 gun to dry the surface;

[0030] (2) Diethanolamine (2.45 mL) and tetrabutyl titanate (5.1 mL) were sequentially dissolved in absolute ethanol (33.6 mL) under stirring, and then stirred for 2 h. Then, absolute ethanol (5 mL) and ultrapure water (0.45 mL) were added to the solution, and the mixture was further stirred for 2 h, and then allowed to stand for 24 h; transparent TiO was obtained 2 precursor sol;

[0031] (3) The obtained 2.0×2.0cm 2 Si / SiO 2 The substrate was placed in a UV-ozone cleaner for 20 min, and 100 μL of TiO was taken with a pipette. 2 The precursor sol was placed on all the obtained sprayed substrates at 3000 r min. -1 Spin coating a...

Embodiment 2

[0042] (1) 2.0×2.0cm 2 Si / SiO 2 The substrate was placed in an acetone solution for ultrasonic cleaning for 15 min, then placed in an isopropanol (IPA) solution for ultrasonic cleaning for 15 min, then the IPA was heated to boiling, the substrate surface was fumigated with IPA hot steam for 1 minute, and then N 2 gun to dry the surface;

[0043] (2) Diethanolamine (2.45 mL) and tetrabutyl titanate (5.1 mL) were sequentially dissolved in absolute ethanol (33.6 mL) under stirring, and then stirred for 2 h. Then, absolute ethanol (5 mL) and ultrapure water (0.45 mL) were added to the solution, and the mixture was further stirred for 2 h, and then allowed to stand for 24 h; transparent TiO was obtained 2 precursor sol;

[0044] (3) The obtained 2.0×2.0cm 2 Si / SiO 2 The substrate was placed in a UV-ozone cleaner for 20 min, and 100 μL of TiO was taken with a pipette. 2 The precursor sol was placed on all the obtained sprayed substrates at 3000 r min. -1 Spin coating at a spe...

Embodiment 3

[0052] (1) 2.0×2.0cm 2 Si / SiO 2 The substrate was placed in an acetone solution for ultrasonic cleaning for 15 min, then placed in an isopropanol (IPA) solution for ultrasonic cleaning for 15 min, then the IPA was heated to boiling, the substrate surface was fumigated with IPA hot steam for 1 minute, and then N 2 gun to dry the surface;

[0053] (2) Diethanolamine (2.45 mL) and tetrabutyl titanate (5.1 mL) were sequentially dissolved in absolute ethanol (33.6 mL) under stirring, and then stirred for 2 h. Then, absolute ethanol (5 mL) and ultrapure water (0.45 mL) were added to the solution, and the mixture was further stirred for 2 h, and then allowed to stand for 24 h; transparent TiO was obtained 2 precursor sol;

[0054] (3) The obtained 2.0×2.0cm 2 Si / SiO 2 The substrate was placed in a UV-ozone cleaner for 20 min, and 100 μL of TiO was taken with a pipette. 2 The precursor sol was placed on all the obtained sprayed substrates at 3000 r min. -1 Spin coating at a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com