Beneficiation method for recovering strong magnetic iron ore from carbon slurry process gold extraction tailings

A beneficiation method and strong magnetic technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., to achieve the effects of less investment, improved grade and recovery, and easy control

Active Publication Date: 2022-06-10

YUNNAN GOLD MINING GRP +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The technical problem to be solved by the present invention is that the iron-containing ore needs to be ground very finely, and a large part of the strong magnetic iron ore particle size exceeds the recovery of the weak magnetic separator The optimal particle size, the recovery effect of strong magnetic iron ore is poor, or a large amount of strong magnetic iron ore enters into weak magnetic iron ore, and can only be treated at a low price, resulting in damage to the mine's due interests, and when the content of strong magnetic iron ore is large , causing the blockage of the strong magnetic machine, and the production cannot be carried out normally. A beneficiation method for comprehensively and efficiently recovering strong magnetic iron ore from the tailings of gold extraction by carbon slurry method is provided.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

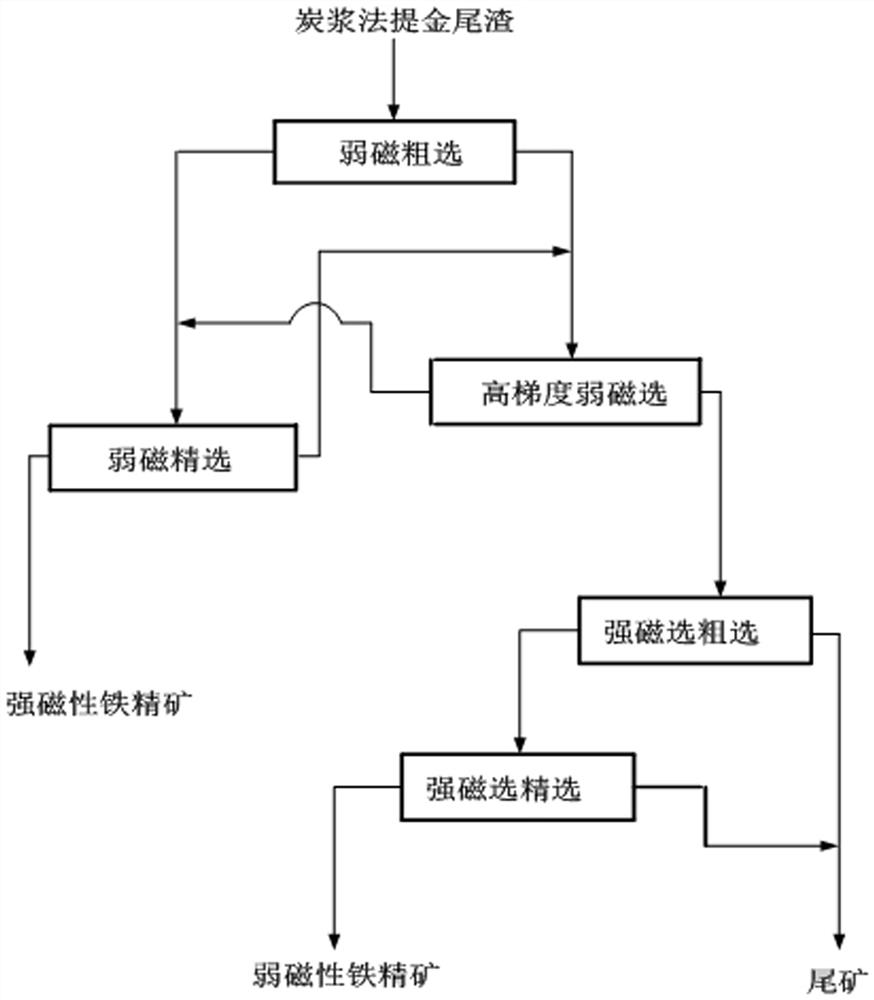

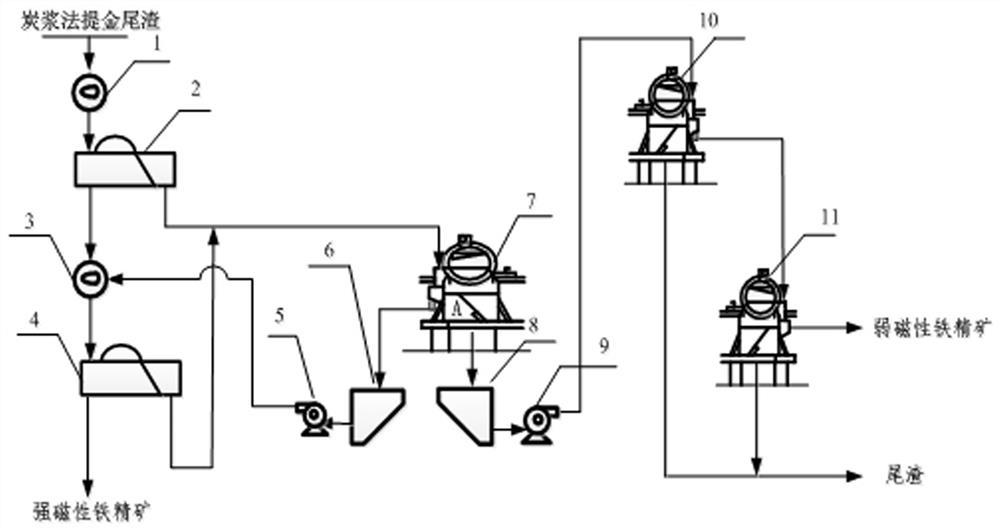

The beneficiation method comprises the following steps: (1) weak magnetic roughing: the magnetic induction intensity of a weak magnetic separator is 0.2 T-0. 4T, and the mass concentration of ore pulp is controlled to be 15%-30%; (2) high-gradient weak magnetic scavenging is conducted, specifically, the diameter of a magnetic medium of a high-gradient weak magnetic separator is 3-8 mm, the background magnetic induction intensity is 0.3-0.5 T, and the mass concentration of ore pulp is controlled to be 15%-30%; (3) low-intensity magnetic concentration of rough concentrate: the magnetic induction intensity of a low-intensity magnetic separator is 0.2 T-0. 3T, and the mass concentration of ore pulp is controlled to be 15%-30%; (4) performing high-gradient weak magnetic scavenging on the middlings I and the tailings I; (5) the diameter of a magnetic medium of a strong magnetic separator for strong magnetic roughing of the tailings II is 1.5 mm, the background magnetic induction intensity is 1.0-2.0 T, and the mass concentration of ore pulp is controlled to be 18%-20%; and (6) the diameter of a magnetic medium of a high-intensity magnetic separator is 1.5 mm, the background magnetic induction intensity is 0.8-0.9 T, and the mass concentration of ore pulp is controlled to be 10%-15%. According to the method, the ferromagnetic iron ore can be directly recovered through magnetic separation, and the recovery rate of the ferromagnetic iron is greatly improved.

Description

Technical field [0001] The invention involves a proclaimed method of recycling strong magnetic iron ore from the golden tail residue of the carbon slurry method. Background technique [0002] The mineral selection is based on the physical and chemical properties of different minerals in the ore. After crushing and grinding the ore, the re -selection method, flotation method, magnetic selection method, electrical selection method, etc. will be used.The useful minerals of symbiotic (accompaniment) are separated as much as possible to remove or reduce harmful impurities to obtain the process of smelting or other industries.Mining can enable the useful components in minerals, reduce the consumption of fuel and transportation in the smelting or other processing processes, and enable low -quality ore to get economic use.At present, magnetic selection is the main mineral method of iron minerals, including weak magnetic selection, medium magnetic field magnetic selection, and strong magn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03C1/30

CPCB03C1/30

Inventor 段胜红姜亚雄高起方谢恩龙陈禄政先永骏

Owner YUNNAN GOLD MINING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com