Method for changing surface wettability of invar alloy through femtosecond laser

A technology of Invar alloy and femtosecond laser, which is applied in the field of changing the surface wettability of Invar alloy, can solve the problems that micron-level morphology cannot be processed, and it is difficult to reach the ablation threshold of Invar alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

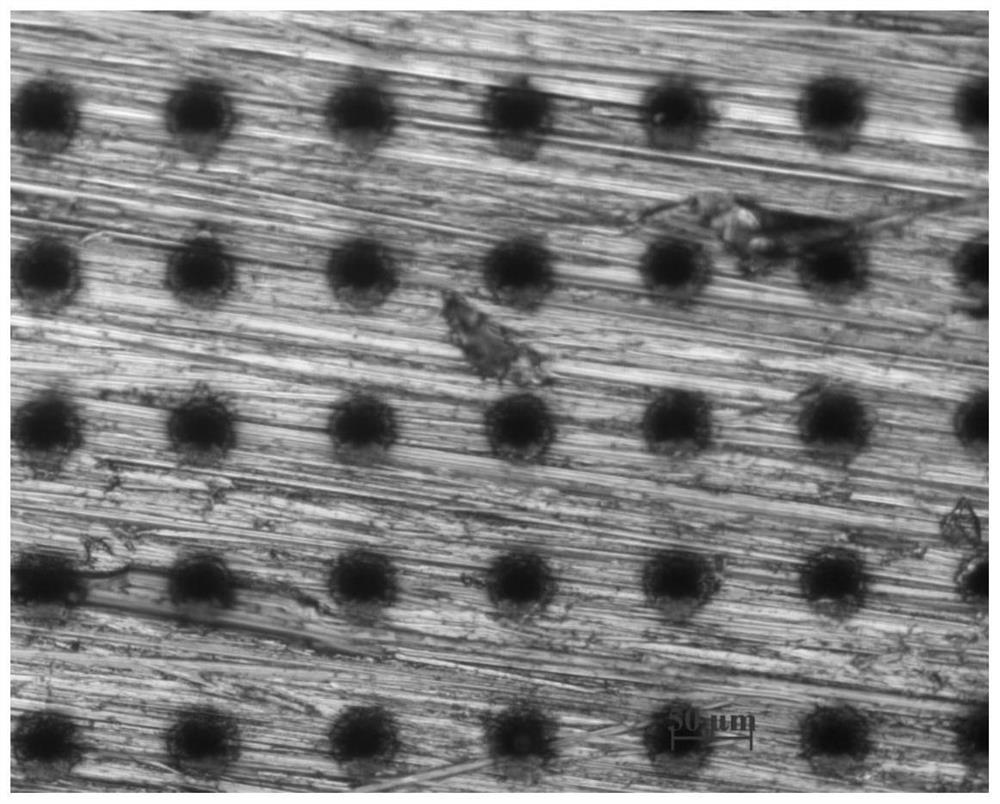

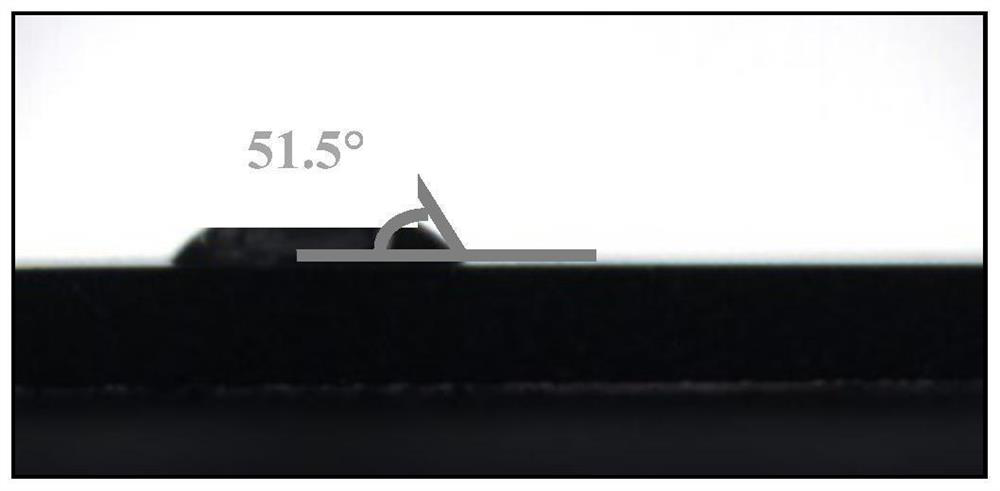

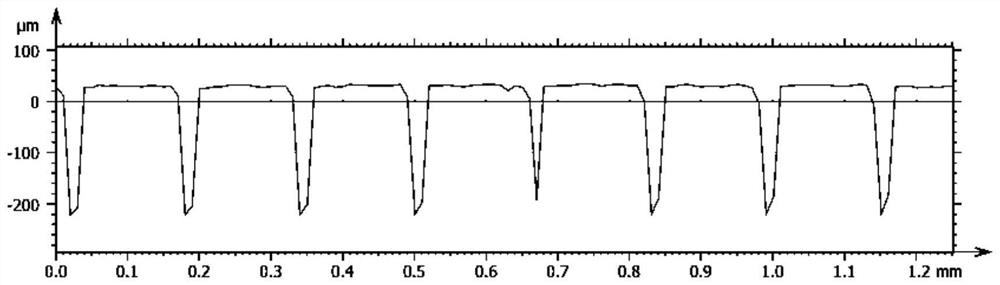

[0046] The invar base material is cut by wire cutting, and the invar base material is polished with 240-grit water-grinding paper until the silver-white metallic luster is exposed. By setting the scanning path of the femtosecond laser as discontinuous non-moving processing, that is, single-point array arrangement, the point spacing is 160 μm, the processing power is 12 W, the number of repetitions is 1, and the single-point dwell time is 10000 μs, and micro-pits are prepared on the surface. shape (such as figure 1 ) shown. Then, the processed Invar alloy was ultrasonically cleaned for 10 minutes, and the in-situ water wetting angle was detected on its surface, and the results were as follows figure 2 shown. The cross section of the micropit is V-shaped (such as image 3 ), that is, the pits have a conical shape (such as Figure 4 ). Compare the original morphology with the wetting angle (e.g. Figure 5 It can be found that the Invar alloy is hydrophilic under this morph...

Embodiment 2

[0048] The invar base material is cut by wire cutting, and the invar base material is polished with 240-grit water-grinding paper until the silver-white metallic luster is exposed. By setting the scanning path of the femtosecond laser to continuous processing, that is, the processing path is a straight line, the line spacing is 160 μm, the processing power is 12 W, the number of scans is 1, and the scanning rate is 1000 mm / s, the microgrooves are prepared on the surface (such as Image 6 ) shown. Then, the processed Invar alloy was ultrasonically cleaned for 10 minutes, and the in-situ water wetting angle was detected on its surface, and the results were as follows Figure 7 shown. The cross-section of the microgroove is V-shaped (such as Figure 8 ), that is, the microgrooves are in the shape of inverted triangular pyramids and inverted triangular strips (such as Figure 9 ). Compare the original morphology with the wetting angle (e.g. Figure 5 ), it can be found that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com