Functional low-lactose prebiotic liquid goat milk and preparation method thereof

A low-lactose, prebiotic technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of low lactose content of transglycosidic active lactase, synthesis of galactose into galactooligosaccharides, high content of galactooligosaccharides, etc. , to increase the content of galacto-oligosaccharides, improve the hydrolysis rate of lactose, and improve the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

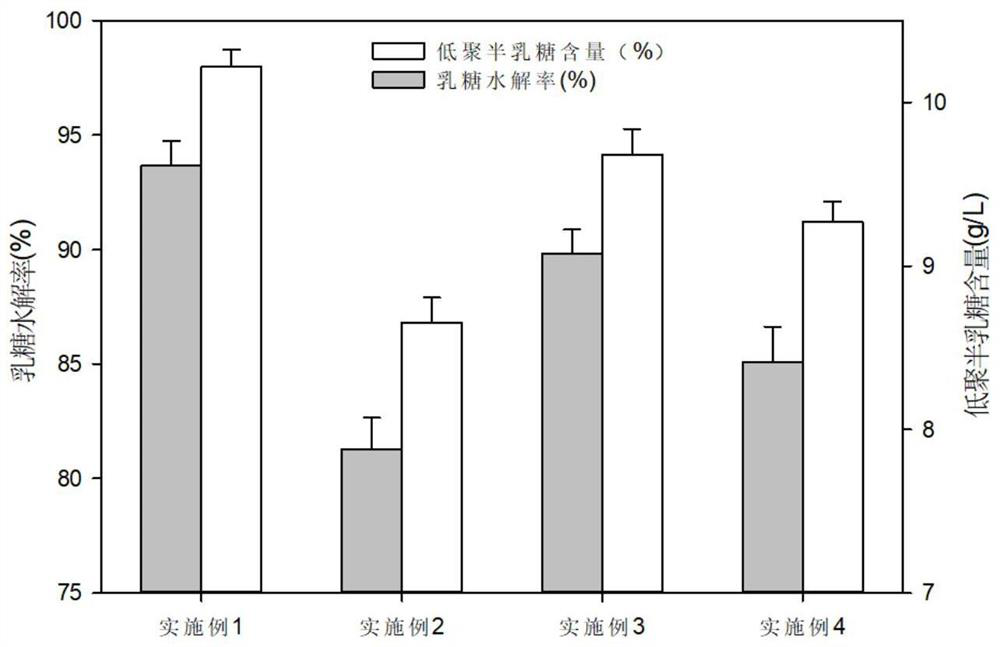

[0027] Step 1. Add lactase K and lactase P in a volume ratio of 3:1 to the goat milk that is pasteurized at 65°C for 15 minutes and cooled to 50°C, so that the final lactase content is 0.8 g / L;

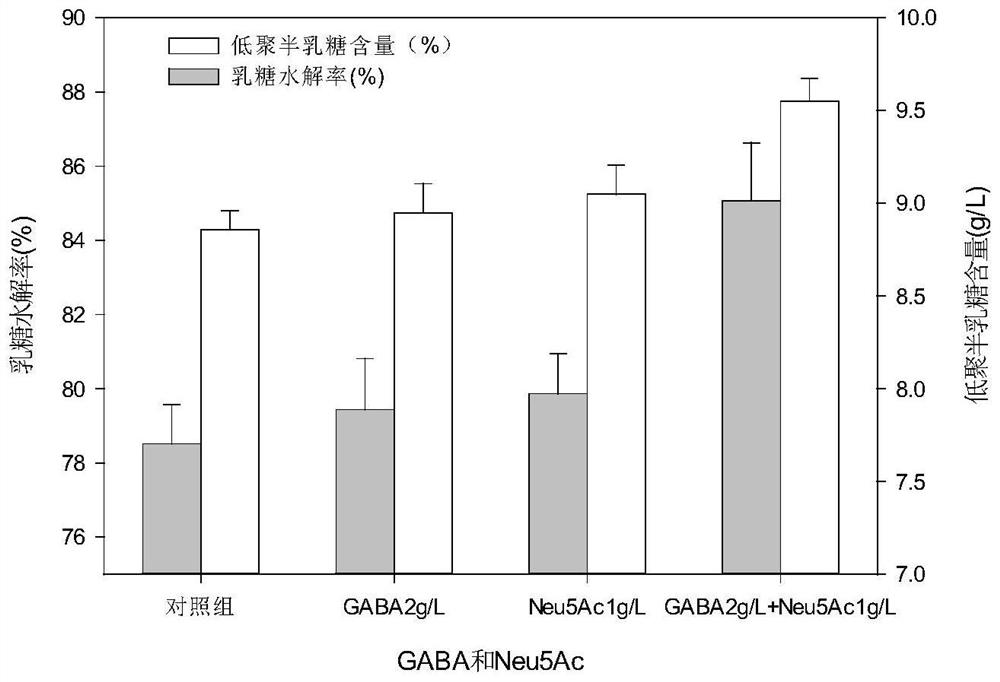

[0028] Step 2: Add γ-aminobutyric acid and N-acetylneuraminic acid to make the final concentrations 2g / L and 1g / L respectively, stir evenly and then enzymolysis at a constant temperature of 50°C for 3h;

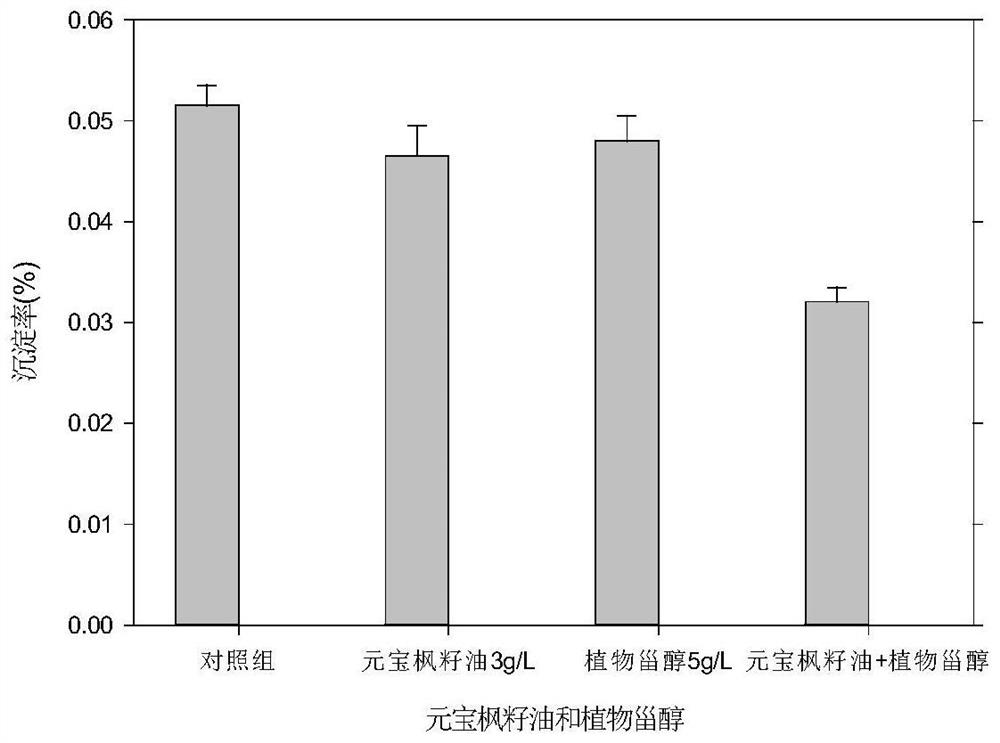

[0029] Step 3. Add Baofeng seed oil and phytosterols to make the concentrations 3g / L and 5g / L respectively, homogenize under high pressure for 10min, keep at 140°C for 2s after sterilization, and pack to obtain functional low-lactose prebiotic liquid goat milk. The prepared functional prebiotic liquid goat milk has a shelf life of 60 days at room temperature.

[0030] The lactose / galactose kit was used to measure the content of lactose and galactose in the goat milk before and after the enzymatic hydrolysis of Example 1, and it was detected that the lactose content in the functional ...

Embodiment 2

[0032] Step 1. Lactase K and lactase P are added to the goat milk that is pasteurized at 65°C for 15 minutes and cooled to 50°C in a volume ratio of 2:1, so that the final lactase content is 0.6 g / L;

[0033] Step 2: Add γ-aminobutyric acid and N-acetylneuraminic acid to make the final concentrations 2g / L and 1g / L respectively, stir evenly and then enzymolysis at 45°C for 2h;

[0034] Step 3, adding Baofeng seed oil and phytosterols to make the concentrations 3g / L and 5g / L respectively, homogenizing under high pressure for 10min, sterilizing at 85°C for 10s, and packaging to obtain functional low-lactose prebiotic liquid goat milk, The prepared functional prebiotic liquid goat milk was refrigerated at 4°C for 7 days.

[0035] The lactose / galactose kit was used to measure the content of lactose and galactose in the goat milk before and after the enzymatic hydrolysis of Example 2. It was detected that the lactose content in the functional prebiotic liquid goat milk prepared in E...

Embodiment 3

[0037] Step 1. Add lactase K and lactase P in a volume ratio of 2:1 to the goat milk that is pasteurized at 65°C for 15 minutes and cooled to 50°C, so that the final lactase content is 0.7 g / L;

[0038] Step 2: Add γ-aminobutyric acid and N-acetylneuraminic acid to make the final concentrations 2g / L and 1g / L respectively, stir evenly, and then enzymolysis at a constant temperature of 50°C for 2.5h;

[0039] Step 3. Add Baofeng seed oil and phytosterol to make the concentrations 3g / L and 5g / L respectively, homogenize under high pressure for 10min, keep at 132°C for 4s after sterilization, and pack to obtain functional low-lactose prebiotic liquid goat milk. The prepared functional prebiotic liquid goat milk has a shelf life of 60 days at room temperature.

[0040] The lactose / galactose kit was used to measure the content of lactose and galactose in the goat milk before and after the enzymatic hydrolysis of Example 3. It was detected that the lactose content in the functional pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com