Welding method and device for medium-thickness aluminum alloy plate

A technology of aluminum alloy plate and welding method, which is applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high strength of aluminum alloy joints, less pores and inclusions, and small heat-affected zone, so as to reduce pores and Inclusion, arc stiffness is good, and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

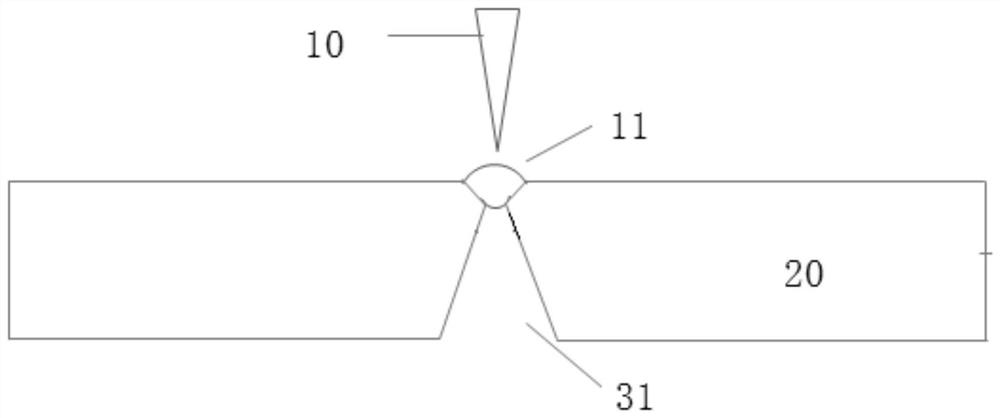

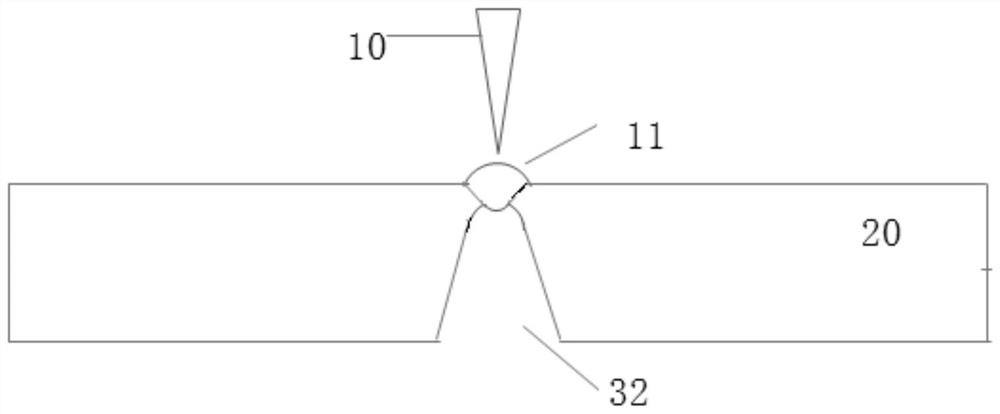

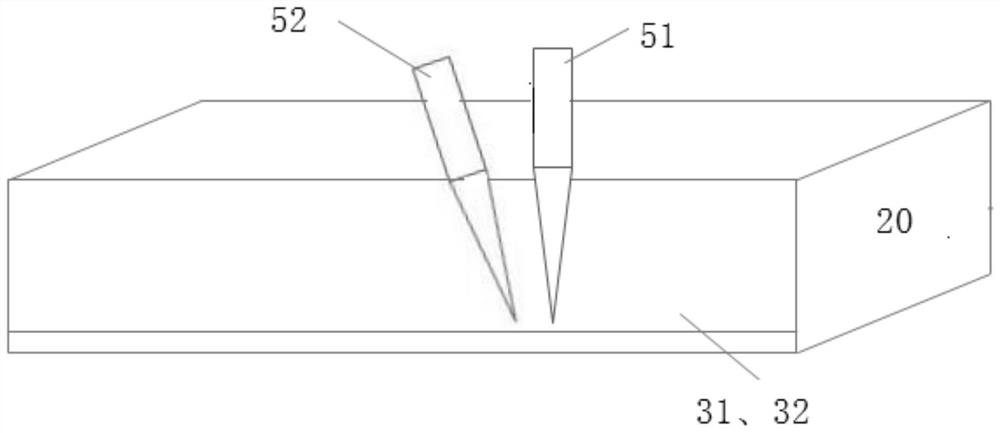

[0033] The present invention will be described in detail below with reference to the accompanying drawings.

[0034] Detailed exemplary embodiments are disclosed below. However, specific structural and functional details disclosed herein are merely for purposes of describing example embodiments.

[0035] It should be understood, however, that this invention is not limited to the specific exemplary embodiments disclosed, but covers all modifications, equivalents, and alternatives falling within the scope of this disclosure. In the description of all the figures, the same reference numerals refer to the same elements.

[0036] Referring to the accompanying drawings, the structures, proportions, sizes, etc. shown in the drawings in this specification are only used to cooperate with the contents disclosed in the specification, so as to be understood and read by those who are familiar with the technology, and are not intended to limit the scope of the present invention. The limit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap