Preparation method of pollution-free environment-friendly epoxy self-adhesive paint for electromagnetic wire

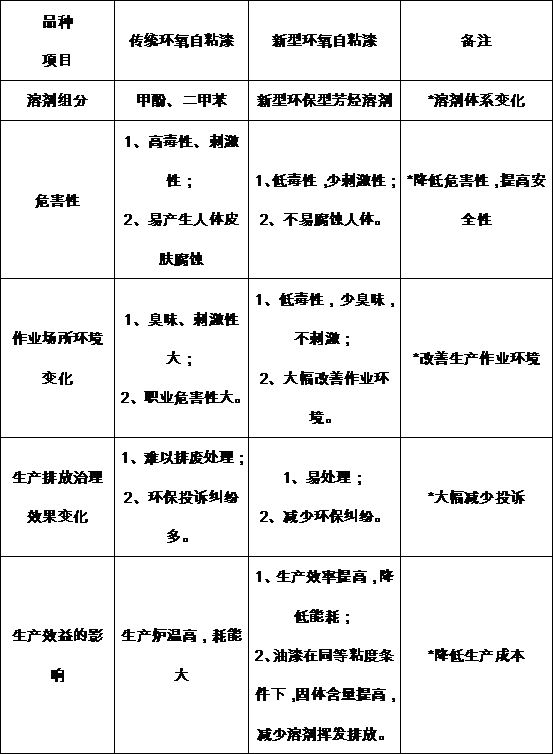

A technology of electromagnetic wire and self-adhesive paint, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of phenolic solvents such as corrosiveness, toxicity, carcinogenicity of xylene, occupational health hazards, etc., to achieve a clear and transparent appearance, Excellent oil and water resistance, no mechanical impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

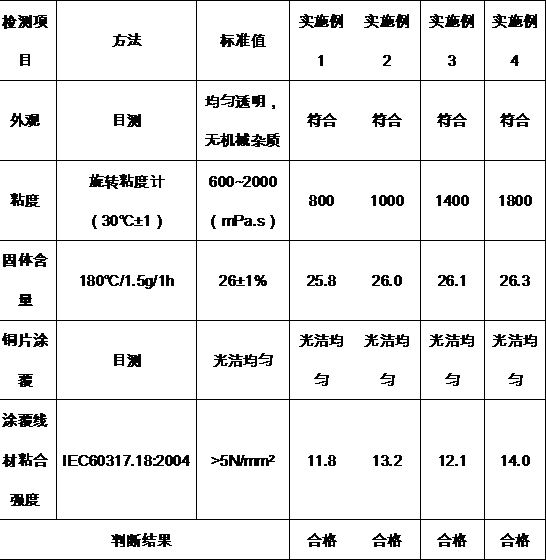

Examples

Embodiment 1

[0038] A method for preparing a pollution-free and environment-friendly epoxy self-adhesive paint for electromagnetic wires, comprising the following steps:

[0039] Step 1: In parts by mass, take 288 parts of diethylene glycol monobutyl ether, 288 parts of diethylene glycol dimethyl ether, and 144 parts of 2-hydroxypropyl methyl ether into a reaction kettle with a condensation reflux device, stir and mix evenly , heat up to 35 ℃, put in phenoxy epoxy resin PKHH / PKHC ratio of 150 / 50 parts in batches, after the addition, stir and heat up to 85 ℃, keep stirring for 2 hours until the resin is fully dissolved, and cool to 45 ℃ get semi-finished product A;

[0040] Step 2: In parts by mass, take 16 parts of diethylene glycol monobutyl ether, 16 parts of diethylene glycol dimethyl ether, and 8 parts of 2-hydroxypropyl methyl ether, put them into a reaction kettle with a condensation reflux tube, and stir evenly , heat up to 40°C, put in 40 parts of bisphenol A epoxy resin, stir eve...

Embodiment 2

[0044] A method for preparing a pollution-free and environment-friendly epoxy self-adhesive paint for electromagnetic wires, comprising the following steps:

[0045] Step 1: In parts by mass, take 238 parts of diethylene glycol monobutyl ether, 238 parts of diethylene glycol dimethyl ether, and 204 parts of 2-hydroxypropyl methyl ether into a reaction kettle with a condensation reflux device, stir and mix evenly , heat up to 40 ℃, put in the phenoxy epoxy resin PKHH / PKHC ratio of 120 / 80 parts in batches, after the addition is completed, stir and heat up to 90 ℃, keep stirring for 2h, until the resin is fully dissolved, cool down to 50 ℃ get semi-finished product A;

[0046] Step 2: In parts by mass, take 15 parts of diethylene glycol monobutyl ether, 15 parts of diethylene glycol dimethyl ether, and 14 parts of 2-hydroxypropyl methyl ether, put them into a reaction kettle with a condensation reflux tube, and stir evenly , heat up to 42°C, put in 44 parts of bisphenol A epoxy re...

Embodiment 3

[0050] A preparation method of pollution-free and environment-friendly epoxy self-adhesive paint for electromagnetic wire, comprising the following steps:

[0051] Step 1: In parts by mass, take 204 parts of diethylene glycol monobutyl ether, 204 parts of diethylene glycol dimethyl ether, and 272 parts of 2-hydroxypropyl methyl ether into a reaction kettle with a condensation reflux device, stir and mix evenly , heat up to 42°C, put in phenoxy epoxy resin PKHH / PKHC ratio of 100 / 100 parts in batches, after the addition is completed, stir and heat up to 90°C, keep stirring for 3h, until the resin is fully dissolved, cool down to 52°C get semi-finished product A;

[0052] Step 2: In parts by mass, take 15 parts of diethylene glycol monobutyl ether, 15 parts of diethylene glycol dimethyl ether, and 20 parts of 2-hydroxypropyl methyl ether, put them into a reaction kettle with a condensation reflux tube, and stir evenly , heat up to 45°C, put in 50 parts of bisphenol A epoxy resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com