Processing method of composite raw materials for crops

A raw material processing and composite technology, applied in the fields of seed and rhizome processing, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inability to protect the brush head, brush head collision, brush head wear, etc., to reduce loss, Reduce brush head wear and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

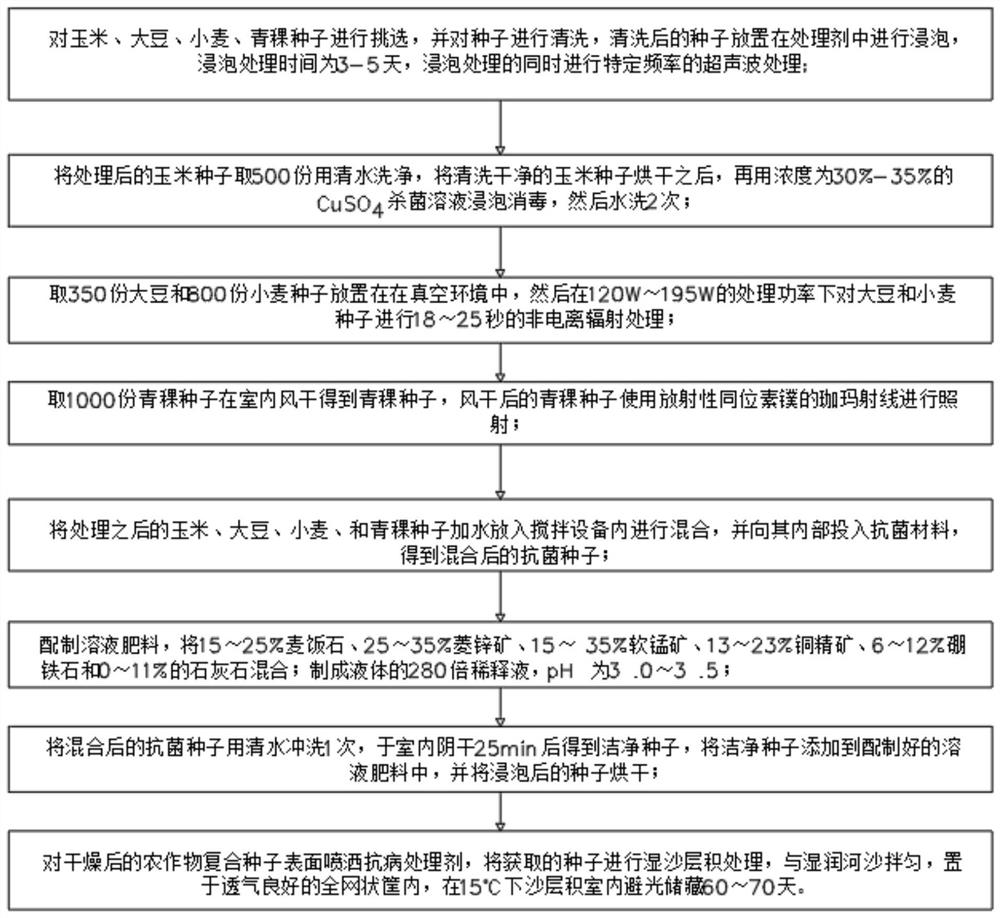

[0040] see figure 1 , the present invention provides a technical solution: a method for processing composite raw materials for crops, consisting of the following steps:

[0041] S1. Select the seeds of corn, soybean, wheat, and highland barley, and clean the seeds. The cleaned seeds are placed in the treatment agent for soaking. The soaking time is 3-5 days. Ultrasonic waves of a specific frequency are carried out while soaking. deal with;

[0042] S2. Wash 500 parts of the treated corn seeds with water, dry the cleaned corn seeds, and then use CuSO with a concentration of 30%-35%. 4 Soak in sterilizing solution for disinfection, then wash with water twice;

[0043] S3, taking 350 parts of soybeans and 800 parts of wheat seeds and placing them in a vacuum environment, and then treating the soybeans and wheat seeds with non-ionizing radiation for 18 to 25 seconds at a processing power of 120W to 195W;

[0044] S4. Take 1000 parts of highland barley seeds and dry them indoors...

Embodiment 2

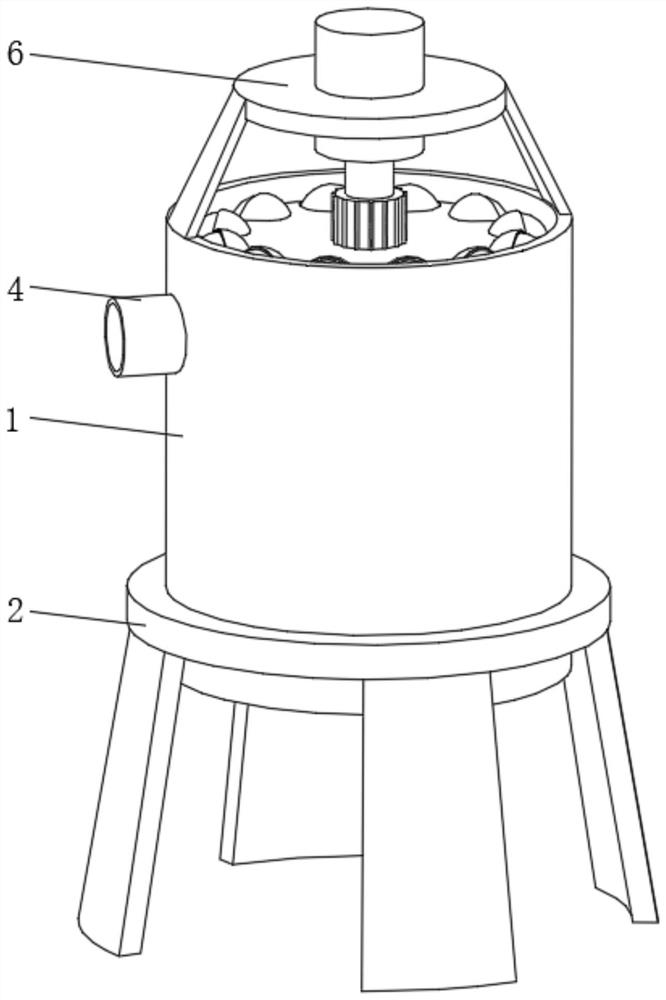

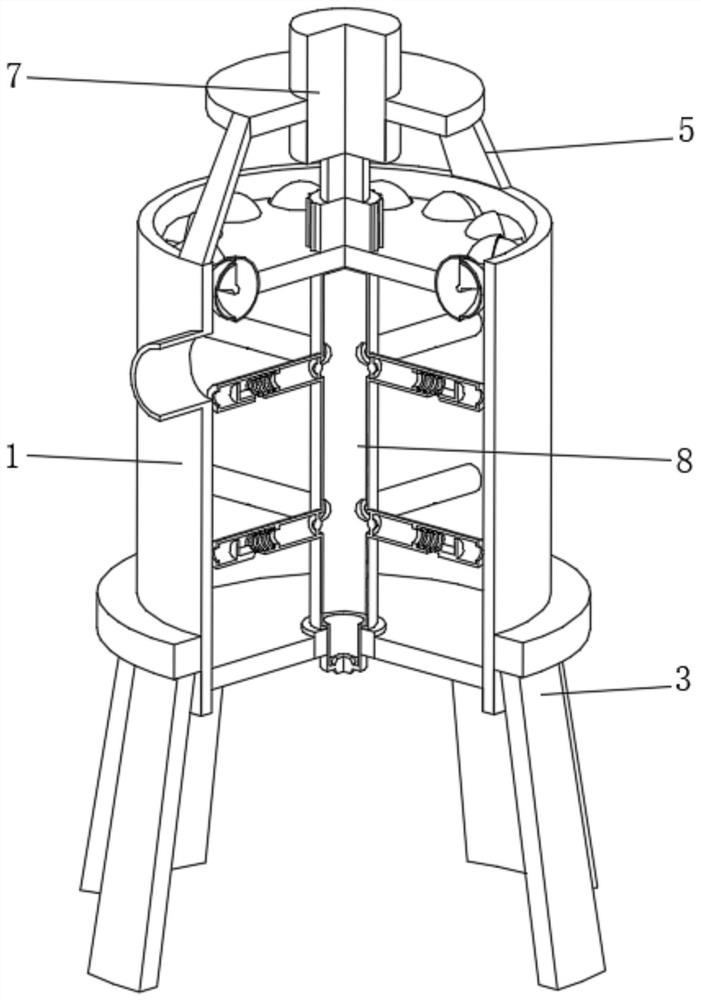

[0050] see Figure 1-Figure 5 , the present invention provides a technical solution: on the basis of Embodiment 1, a composite raw material processing method for crops, the mixing device includes a casing 1, and a fixed ring plate 2 is fixedly connected to the outer side of the casing 1 near the bottom, and the fixed The bottom of the ring plate 2 is fixedly connected with a support base 3, the inner wall of the shell 1 is connected with a feed pipe 4, and the top of the shell 1 is symmetrically installed with a fixed support rod 5, and the end of the fixed support rod 5 away from the shell 1 is fixedly connected with a top fixing plate 6. The top of the top fixing plate 6 is fixedly connected with an electric telescopic rod 7, and the end of the electric telescopic rod 7 close to the shell 1 is fixedly connected with a discharge device 8;

[0051] The discharge device 8 includes a driving motor 81, the output end of the driving motor 81 is fixedly connected with a rotating di...

Embodiment 3

[0059] see Figure 1-Figure 6 , the present invention provides a technical solution: on the basis of Embodiment 1, the mixing and feeding device 85 includes a mixing tube 851, one end of the mixing tube 851 is provided with a side water outlet 852, and the bottom of the mixing tube 851 is provided with a bottom The water outlet 853, the inner wall of the mixing tube 851 near the bottom water outlet 853 is fixedly connected with the limit ring plate 854, and the side of the limit ring plate 854 close to the bottom water outlet 853 is fixedly connected with a return spring 855, and the return spring 855 is far away from the limit. One end of the bit ring plate 854 is fixedly connected with an arc-shaped water retaining plate 856, and one end of the arc-shaped water retaining plate 856 away from the return spring 855 is fixedly connected with a circular water retaining plate 857, and the inner wall of the mixing pipe 851 is close to the water storage pipe 83. The location is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com