Cooking pot and preparation method thereof

A technology for cookware and heat conduction layer, which is applied in welding equipment, manufacturing tools, table utensils, etc., can solve the problems of poor heat conduction performance of iron cookware, and achieve the purpose of reducing food scorching and sticking to the pan, ensuring heating, and saving consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

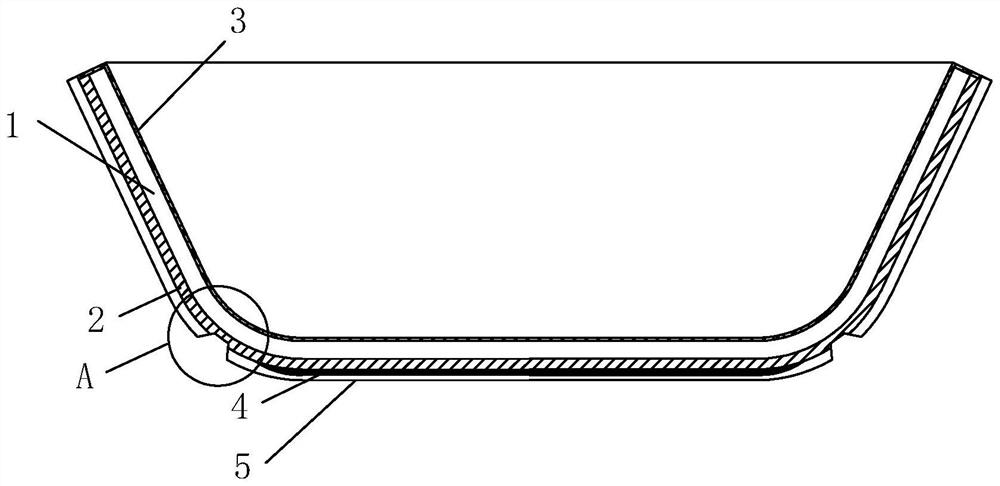

[0036] The cooking pot of this embodiment, such as figure 1 shown, including:

[0037] Iron base 1, which is refined iron or cast iron; for cooking with open flames or induction;

[0038] The thermal conductive layer 2 is close to the lower surface of the iron base 1, and the thermal conductive layer 2 is a copper layer or a silver layer;

[0039] The stainless layer 3 is formed on the upper surface and the top surface of the iron base 1;

[0040] The magnetic conductive layer 4 covers the bottom surface of the thermal conductive layer 2;

[0041] The anti-corrosion layer 5 covers the side surface of the thermal conductive layer 2 and the bottom surface of the magnetic conductive layer 4 .

[0042] In this structure, the heat-conducting layer 2 made of copper or silver has good thermal conductivity, and is arranged on the lower surface of the iron base 1, which can quickly conduct heat to the entire iron base 1 to ensure uniform heating and reduce heat accumulation. Effect...

Embodiment 2

[0049] The preparation method of the cooking pot of the present embodiment includes:

[0050] Step 1, use 20 to 60 mesh irregular brown corundum sand grains to sandblast the surface of the iron substrate;

[0051] Step 2, spray a thermally conductive layer with a thickness of 0.1-0.35mm on the lower surface of the iron substrate by high-pressure cold spraying, high-pressure cold spraying, the working gas used is nitrogen or argon, and the speed of the spray gun during spraying is 1-1000mm / s, the heating temperature of the spray gun is 300-1000°C, and the spraying distance is 5-50mm; during spraying, the speed of the substrate is controlled at 50-500RPM, and the substrate temperature is <200°C; Silver particles, the particle size range is 100-1000 mesh;

[0052] In step 3, a magnetic conductive layer is arranged at the bottom of the heat-conducting layer by cold spraying, plasma thermal spraying, brazing or forging composite method; in this embodiment, the cold spraying proce...

Embodiment 3

[0057] The preparation method of the cooking pot of the present embodiment includes:

[0058] Step 1, use 20 to 60 mesh irregular brown corundum sand grains to sandblast the surface of the iron substrate;

[0059] Step 2, spray a thermally conductive layer with a thickness of 0.1-0.35mm on the lower surface of the iron substrate by high-pressure cold spraying, high-pressure cold spraying, the working gas used is nitrogen or argon, and the speed of the spray gun during spraying is 1-1000mm / s, the heating temperature of the spray gun is 300-1000°C, and the spraying distance is 5-50mm; during spraying, the speed of the substrate is controlled at 50-500RPM, and the substrate temperature is <200°C; Silver particles, the particle size range is 100-1000 mesh;

[0060] In step 3, a magnetic conductive layer is arranged at the bottom of the thermal conductive layer by means of plasma thermal spraying; in this embodiment, the plasma spraying process: the air pressure of the spray gun ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com