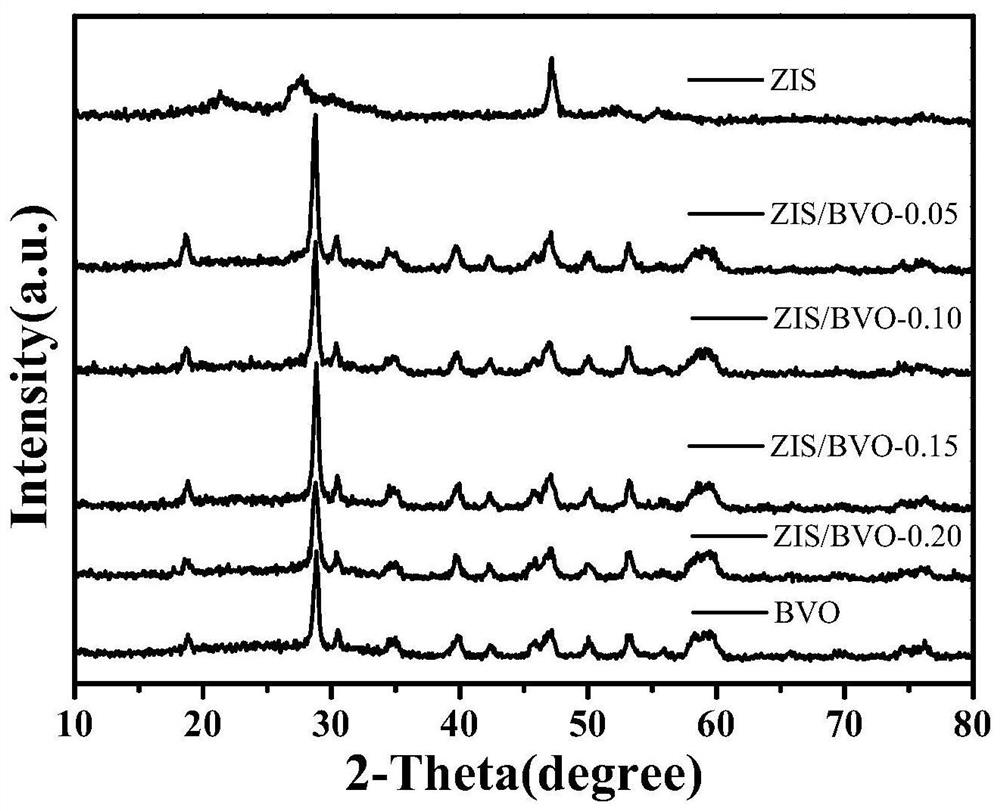

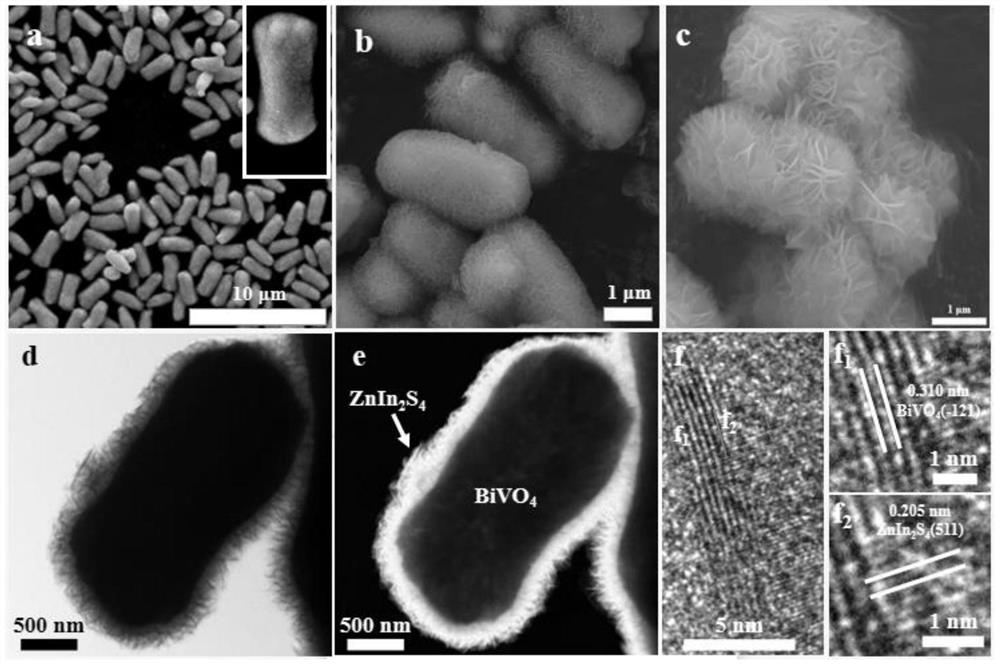

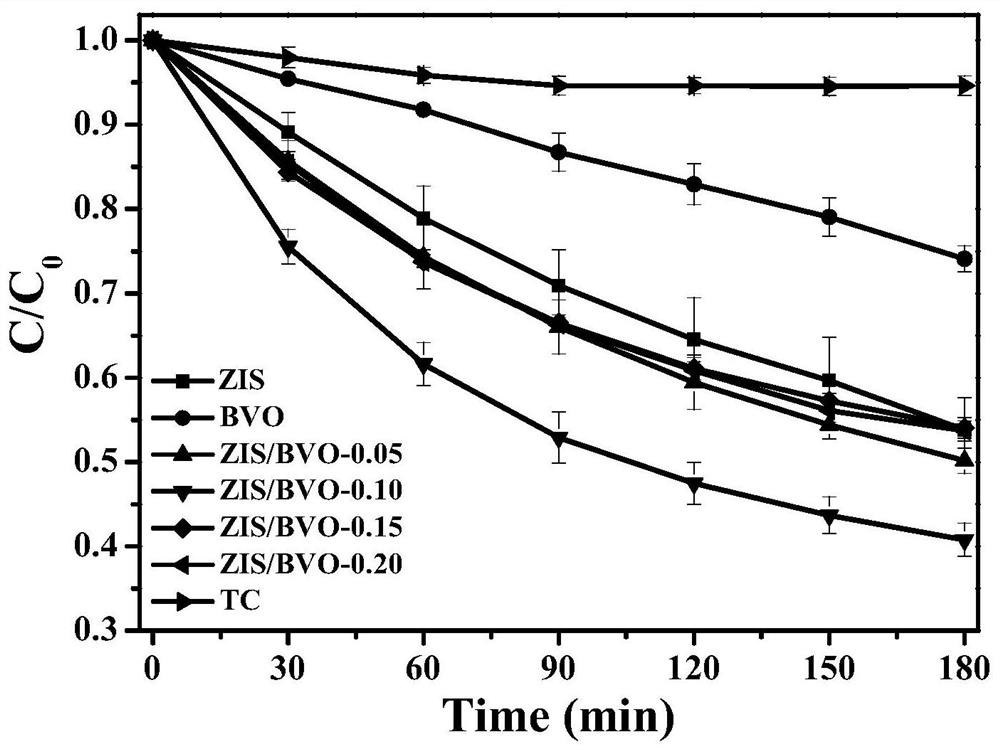

Preparation method and application of ZnIn2S4 nanosheet coated BiVO4 microrod core-shell heterojunction catalyst

A technology of znin2s4 and nanosheets, applied in the fields of environmental management and photocatalysis, can solve the problem of no literature report, and achieve the effect of improving the utilization rate, broadening the absorption range, and improving the reduction and oxidation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 1mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 15ml of ethylene glycol to obtain solution A. 1mmol NH 4 VO 3 Dissolve in 15ml deionized water to obtain solution B. Solution B was slowly dropped into solution A with stirring, the resulting mixture was transferred into a 40 ml Teflon-lined autoclave and heated at 140 °C for 24 h. The reacted material was washed three times with deionized water and absolute ethanol, and dried at 60 °C for 10 h to obtain BiVO 4 Material.

[0028] (2) Weigh 0.05mmol of BiVO obtained in step 1 4 Disperse in 20ml of dilute hydrochloric acid solution with pH=2.5, add 3ml of glycerin and stir. Then add 0.2mmol ZnCl 2 , 0.2mmol InCl 3 4H 2 O and 0.4mmol thioacetamide were dissolved by ultrasonic stirring. Put the solution in an oil bath and heat it at 80°C for 2h, centrifuge the reacted mixture, wash it with deionized water and absolute ethanol three times, and dry it at 60°C for 10h to obtain ZnIn 2 S 4 / BiVO 4 The composite ma...

Embodiment 2

[0030] (1) Add 1mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 15ml of ethylene glycol to obtain solution A. 1mmol NH 4 VO 3 Dissolve in 15ml deionized water to obtain solution B. Solution B was slowly dropped into solution A with stirring, the resulting mixture was transferred into a 40 ml Teflon-lined autoclave and heated at 140 °C for 24 h. The reacted material was washed three times with deionized water and absolute ethanol, and dried at 60 °C for 10 h to obtain BiVO 4 Material.

[0031] (2) Weigh 0.10 mmol of BiVO obtained in step 1 4 Disperse in 20ml of dilute hydrochloric acid solution with pH=2.5, add 3ml of glycerin and stir. Then add 0.2mmol ZnCl 2 , 0.2mmol InCl 3 4H 2 O and 0.4mmol thioacetamide were dissolved by ultrasonic stirring. Put the solution in an oil bath and heat it at 80°C for 2h, centrifuge the reacted mixture, wash it with deionized water and absolute ethanol three times, and dry it at 60°C for 10h to obtain ZnIn 2 S 4 / BiVO 4 The composite ...

Embodiment 3

[0033] (1) Add 1mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 15ml of ethylene glycol to obtain solution A. 1mmol NH 4 VO 3 Dissolve in 15ml deionized water to obtain solution B. Solution B was slowly dropped into solution A with stirring, the resulting mixture was transferred into a 40 ml Teflon-lined autoclave and heated at 140 °C for 24 h. The reacted material was washed three times with deionized water and absolute ethanol, and dried at 60 °C for 10 h to obtain BiVO 4 Material.

[0034] (2) Weigh 0.15 mmol of BiVO obtained in step 1 4 Disperse in 20ml of dilute hydrochloric acid solution with pH=2.5, add 3ml of glycerin and stir. Then add 0.2mmol ZnCl 2 , 0.2mmol InCl 3 4H 2 O and 0.4mmol thioacetamide were dissolved by ultrasonic stirring. Put the solution in an oil bath and heat it at 80°C for 2h, centrifuge the reacted mixture, wash it with deionized water and absolute ethanol three times, and dry it at 60°C for 10h to obtain ZnIn 2 S 4 / BiVO 4 The composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com