Resourceful treatment method for chrome tanning waste liquid

A processing method and a resource-recycling technology, applied in the field of light industry and environmental protection, can solve the problems of low recovery efficiency of hexavalent chromium, and achieve the effect of improving recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

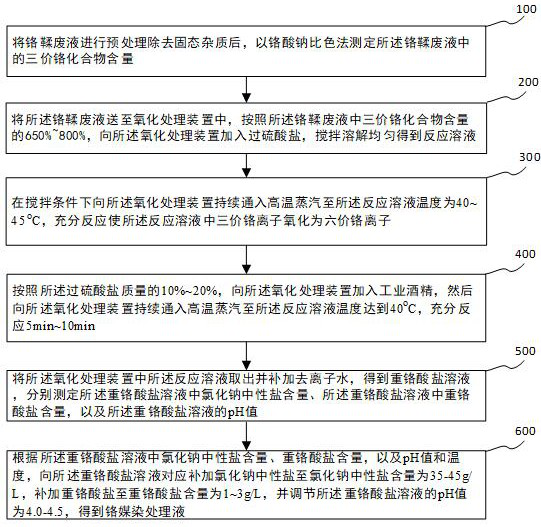

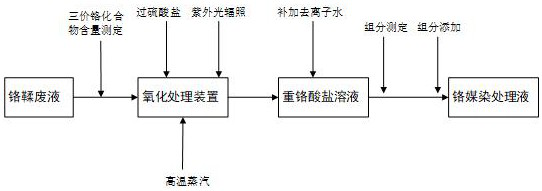

Method used

Image

Examples

Embodiment 1

[0059] (1) After the chrome tanning waste liquor is pretreated by plate and frame filtration to remove solid impurities, the Cr in the chrome tanning waste liquor is determined by the sodium chromate colorimetric method. 2 O 3 The content is 1.1g / L, the content of neutral salt sodium chloride is 53.8g / L, pH=4.1.

[0060] (2) Send 500L of the chrome tanning waste liquid to a volume of 1m 3 In the oxidation treatment device, add 7.15kg to 8.8kg of potassium persulfate to the oxidation treatment device, stir and dissolve evenly.

[0061] (3) Continuously feed high-temperature steam into the oxidation treatment device under stirring conditions, until the temperature of the reaction solution reaches 40-43 o C, the reaction solution is allowed to flow and mix back and forth in the oxidation treatment device under stirring; the oxidation treatment device has a sealed and waterproof UVA type ultraviolet lamp array, with a temperature of 200 μW / cm 2 The intensity of ultraviolet ligh...

Embodiment 2

[0066] (1) After the chrome tanning waste liquor is pretreated by plate and frame filtration to remove solid impurities, the Cr in the chrome tanning waste liquor is determined by the sodium chromate colorimetric method. 2 O 3 The content is 2.8g / L, the content of neutral salt sodium chloride is 58.4g / L, pH=3.9.

[0067] (2) Send 500L of the chrome tanning waste liquid to a volume of 1m 3 In the oxidation treatment device, add 9.4 kg to 11.2 kg of potassium persulfate to the oxidation treatment device, stir and dissolve evenly.

[0068] (3) Continuously feed high-temperature steam into the oxidation treatment device under stirring conditions, until the temperature of the reaction solution reaches 40-43 o C, the reaction solution is allowed to flow and mix back and forth in the oxidation treatment device under stirring; the oxidation treatment device has a sealed and waterproof UVA type ultraviolet lamp array, with a temperature of 200 μW / cm 2 The intensity of ultraviolet li...

Embodiment 3

[0073] (1) After the chrome tanning waste liquor is pretreated by plate and frame filtration to remove solid impurities, the Cr in the chrome tanning waste liquor is determined by the sodium chromate colorimetric method. 2 O 3 The content is 6.5g / L, the content of neutral salt sodium chloride is 76g / L, pH=4.2.

[0074] (2) Send 500L of the chrome tanning waste liquid to a volume of 1m 3 In the oxidation treatment device, add 21.1 kg to 26 kg of potassium persulfate to the oxidation treatment device, stir and dissolve evenly.

[0075] (3) Continuously feed high-temperature steam into the oxidation treatment device under stirring conditions, until the temperature of the reaction solution reaches 40-43 o C, the reaction solution is allowed to flow and mix back and forth in the oxidation treatment device under stirring; the oxidation treatment device has a sealed and waterproof UVA type ultraviolet lamp array, with a temperature of 200 μW / cm 2 The intensity of ultraviolet light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com