Bromination method of butyl rubber

A butyl rubber and brominated technology, applied in the rubber field, can solve the problems of uncontrollable, unstable bromobutyl rubber product quality, and unstable water content of the glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

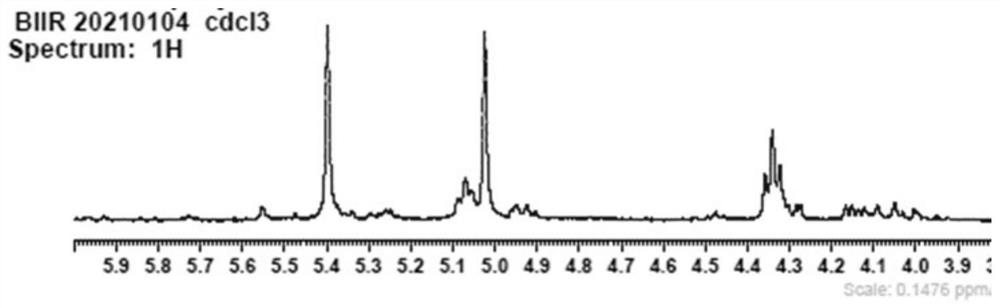

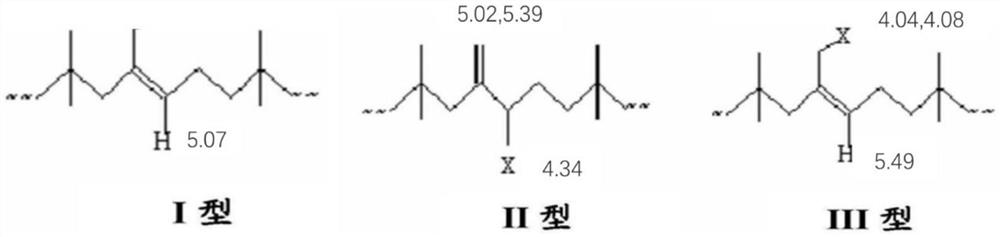

Method used

Image

Examples

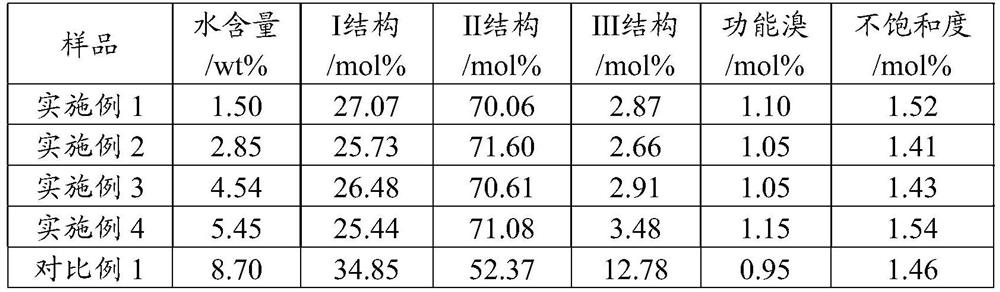

Embodiment 1

[0025] In this example, Br 2 As a brominating agent, the butyl rubber is brominated, and a 2wt% NaOH solution is used as a neutralizing agent to obtain a brominated butyl rubber. Specific steps are as follows:

[0026] 1) Get device glue concentration 15wt% star-branched butyl rubber glue 1000g and place it in 5L reactor, wherein glue water content is 9.8wt%, add 10g 50% NaBr solution and stir for 2h and let stand for water separation, water separation amount It is 94.26g, and the water content after water separation is 1.5wt%.

[0027] 2) Add 2.2mlBr to the glue solution under the condition of shading at 40℃ 2 , and the reaction was stirred for 9 min to obtain a post-reaction glue.

[0028] 3) 230 g of 2% NaOH was added to the glue solution obtained in step 2) and neutralized for 5 min.

[0029] 4) Wash the glue solution obtained in step 3) with water, then add the corresponding stabilizer according to the mass ratio of butyl rubber: calcium stearate: epoxidized soybean o...

Embodiment 2

[0032] In this example, Br 2 As a brominating agent, the butyl rubber is brominated, and a 2wt% NaOH solution is used as a neutralizing agent to obtain a brominated butyl rubber. Specific steps are as follows:

[0033] 1) Get device glue concentration 15wt% star-branched butyl rubber glue 1000g and place it in 5L reactor, wherein glue water content is 9.8wt%, add 10g 50% NaCl solution and stir for 2h and let stand for water separation, the water separation amount is 80.54g, the water content after water separation is 2.85wt%.

[0034] 2) Add 2.2mlBr to the glue solution under the condition of shading at 40℃ 2 , and the reaction was stirred for 9 min to obtain a post-reaction glue.

[0035] 3) 230 g of 2% NaOH was added to the glue solution obtained in step 2) and neutralized for 5 min.

[0036] 4) Wash the glue solution obtained in step 3) with water, then add the corresponding stabilizer according to the mass ratio of butyl rubber: calcium stearate: epoxidized soybean oil...

Embodiment 3

[0039] In this example, Br 2 As a brominating agent, the butyl rubber is brominated, and a 2wt% NaOH solution is used as a neutralizing agent to obtain a brominated butyl rubber. Specific steps are as follows:

[0040] 1) Take 1000g of star-branched butyl rubber glue solution with a glue concentration of 15wt% of the device and place it in a 5L reaction kettle, wherein the glue solution has a water content of 9.8wt%, add 10g of 50% KBr solution and stir for 2h and let stand for water separation, and the water separation amount is 65.10g, the water content after water separation is 4.54wt%.

[0041] 2) Add 2.2mlBr to the glue solution under the condition of shading at 40℃ 2 , and the reaction was stirred for 9 min to obtain a post-reaction glue.

[0042] 3) 230 g of 2% NaOH was added to the glue solution obtained in step 2) and neutralized for 5 min.

[0043] 4) Wash the glue solution obtained in step 3) with water, then add the corresponding stabilizer according to the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com