Mirror surface electrosilvering coating applied to automotive upholstery and preparation method of mirror surface electrosilvering coating

A technology for automotive interior parts and electroplating silver, which is applied in anti-corrosion coatings, coatings and other directions, can solve the problems of the color absorption performance and mirror effect of coatings are not prominently reflected, the scope of application of electroplating silver coatings is limited, and the convenience of use is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

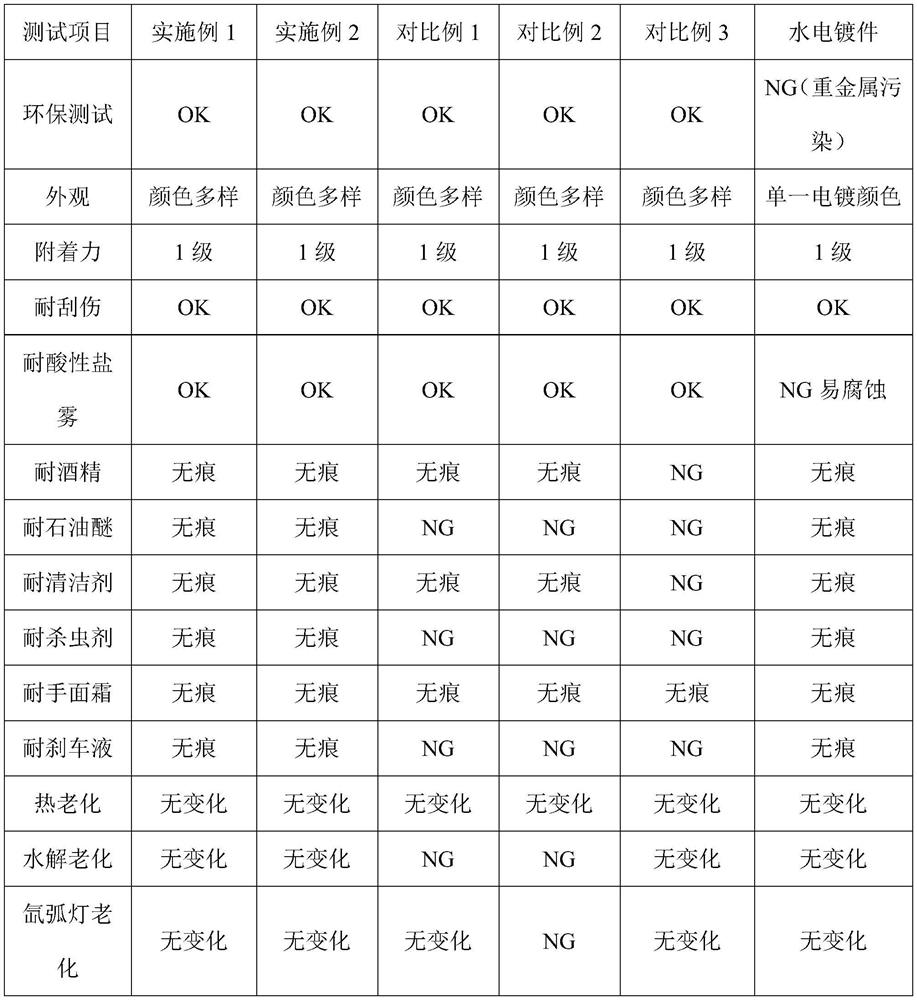

Examples

Embodiment 1

[0048] Embodiment 1 provides a kind of silver electroplating coating applied to the mirror surface of automobile interior parts. By weight, the preparation raw materials include the following components: 15 parts of multifunctional modified polymers, 4 parts of cellulose ester compounds, electroplating silver paste 5 parts, 15 parts of isobutanol, 20 parts of isopropyl acetate, 20 parts of n-butyl acetate, 20 parts of isobutanol, 15 parts of cyclohexanone, and 0.8 parts of BYK-192.

[0049] The multifunctional modified polymer is multifunctional modified polymer A, purchased from Guangzhou Dongfugui Chemical Raw Materials Co., Ltd., the model is SRE-611-25, and the viscosity at 25°C is 65 Pa.s;

[0050] The cellulose ester compound is cellulose ester compound A, purchased from Guangzhou Qihua Chemical Co., Ltd., the model is CAB381-20, the average molecular weight is 70000, the weight content of acetyl group is 13.5%, and the weight content of butyryl group is 37%. %, the weig...

Embodiment 2

[0060] Embodiment 2 provides a kind of silver electroplating paint applied to the mirror surface of automobile interior parts, and the preparation raw materials include the following components in parts by weight: 15 parts of multifunctional modified polymers, 4 parts of cellulose ester compounds, electroplating silver paste 5 parts, isobutanol 10 parts, cyclohexanone 8 parts, isopropyl acetate 20 parts, n-butyl acetate 20 parts, isobutanol 20 parts, cyclohexanone 15 parts, BYK-1920.8 parts, solvent polyester 4 parts of resin.

[0061] The multifunctional modified polymer is multifunctional modified polymer B, which was purchased from Neophos Resin (Foshan) Co., Ltd., the model is Setalux 1184SS-51, the acid value is 2.5-4.7 mgKOH / g, and the acid value is 2.5-4.7 mgKOH / g. The viscosity in ℃ is 4.3-8.7Pa.s;

[0062] The cellulose ester compound is cellulose ester compound B, purchased from Shanghai Jiushi Chemical Co., Ltd., the model is CAB531-1, the average molecular weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com