Efficient preparation method of D-pantoic acid

A pantothenic acid, high-efficiency technology, applied in the field of biosynthesis, can solve the problems of limiting industrial application prospects, complicated reaction steps, long reaction time, etc., to protect the environment and the safety of production workers, avoid cumbersome steps, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

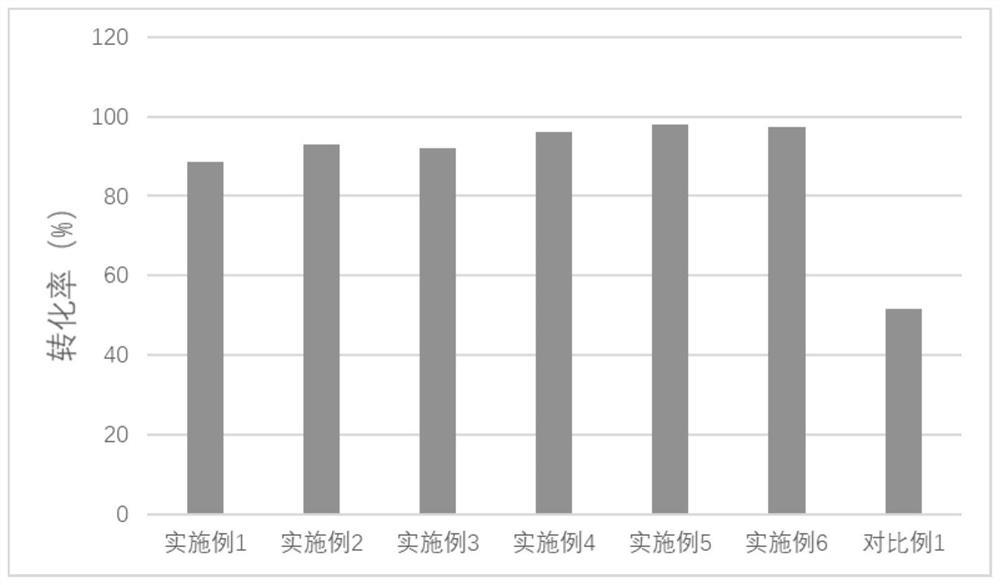

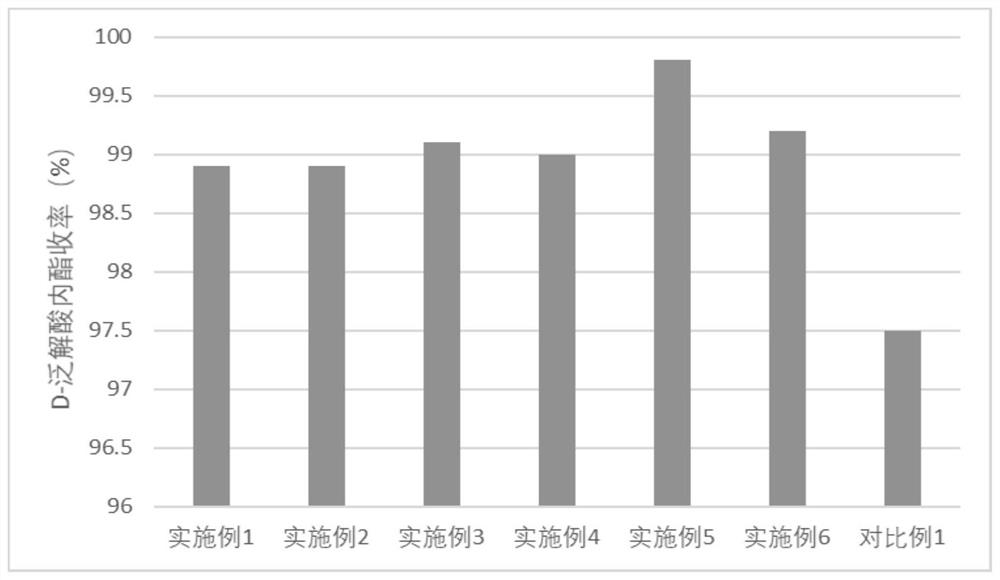

[0050]1) in the reaction vessel, add valine, methyl alcohol, compound enzyme, add water to total volume and be 5L, stir and dissolve, make in the reaction system: valine 249.5g, methyl alcohol 68.25g, L-amino acid deaminase is 10U / L, methanol dehydrogenase was 10U / L, aldolase was 15U / L, ketopantoate reductase was 13U / L, and formate dehydrogenase was 12U / L. Ammonium formate was added in a stream to maintain the concentration of ammonium formate in the reaction solution at 2 g / L. The temperature of the solution was adjusted to 37°C, the pH of the solution was adjusted to 5-7 with ammonia water and dilute sulfuric acid, and the reaction was continued for 20 hours under stirring conditions to obtain a D-pantoic acid solution. figure 1 .

[0051] 2) Take the D-pantoic acid reaction solution, pass it through a ceramic membrane, collect the clear phase solution, pass through a nanofiltration membrane, and adjust the collected clear solution to pH 2.0 or less with sulfuric acid, and...

Embodiment 2

[0053] 1) in the reaction vessel, add valine, methyl alcohol, compound enzyme, add water to total volume and be 5L, stir and dissolve, make in the reaction system: valine 249.5g, methyl alcohol 68.25g, L-amino acid deaminase is 10U / L, methanol dehydrogenase is 10U / L, aldolase is 18U / L, ketopantoate reductase is 14U / L, and formate dehydrogenase is 12U / L. Ammonium formate was added in a stream to maintain the concentration of ammonium formate in the reaction solution at 2 g / L. The temperature of the solution was adjusted to 37°C, the pH of the solution was adjusted to 5-7 with ammonia water and dilute sulfuric acid, and the reaction was continued for 20 hours under stirring conditions to obtain a D-pantoic acid solution. figure 1 .

[0054] 2) Take the D-pantoic acid reaction solution, pass it through a ceramic membrane, collect the clear phase solution, pass through a nanofiltration membrane, and adjust the collected clear solution to pH 2.0 or less with sulfuric acid, and st...

Embodiment 3

[0056] 1) in the reaction vessel, add valine, methyl alcohol, compound enzyme, add water to total volume and be 5L, stir and dissolve, make in the reaction system: valine 300g, methyl alcohol 85g, L-amino acid deaminase are 10U / L, Methanol dehydrogenase was 10U / L, aldolase was 18U / L, ketopantoate reductase was 14U / L, and formate dehydrogenase was 12U / L. Ammonium formate was added in a stream to maintain the concentration of ammonium formate in the reaction solution at 2 g / L. The temperature of the solution was adjusted to 37°C, the pH of the solution was adjusted to 5-7 with ammonia water and dilute sulfuric acid, and the reaction was continued for 20 hours under stirring conditions to obtain a D-pantoic acid solution. figure 1 .

[0057] 2) Take the D-pantoic acid reaction solution, pass it through a ceramic membrane, collect the clear phase solution, pass through a nanofiltration membrane, and adjust the collected clear solution to pH 2.0 or less with sulfuric acid, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com