TBM construction rockburst micro-seismic automatic monitoring and intelligent early warning system and method

An automatic monitoring and early warning system technology, which is applied to earth-moving drilling, manufacturing tools, wellbore/well components, etc., can solve problems such as affecting the accuracy and timeliness of microseismic monitoring, time-consuming manual processing of microseismic data, and work hazards. The effect of reducing labor costs, ensuring time continuity, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the understanding and implementation of the present invention by those of ordinary skill in the art, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0046] The embodiment of the invention discloses an intelligent early warning system for automatic monitoring of microseismic microseisms in TBM construction, so as to solve the problems in the prior art that manual disassembly and assembly of sensors is dangerous and time-consuming, the coordinates of microseismic sensors are difficult to measure, and the accuracy of microseismic monitoring is affected.

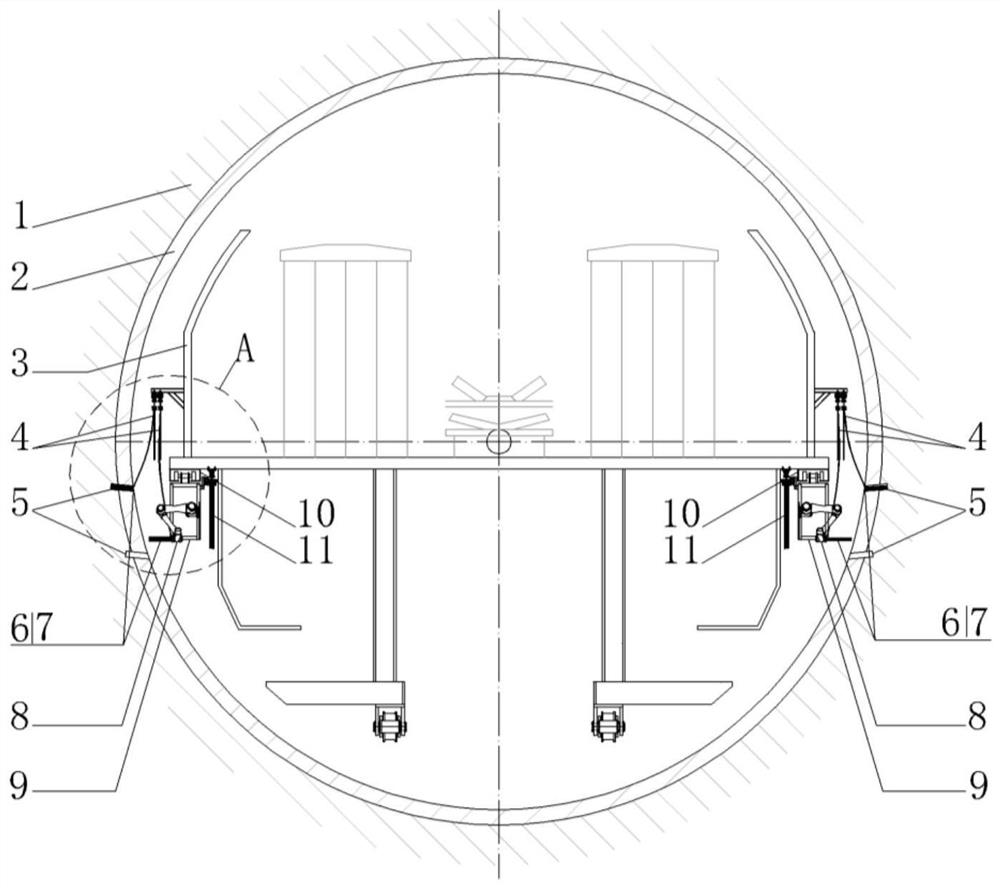

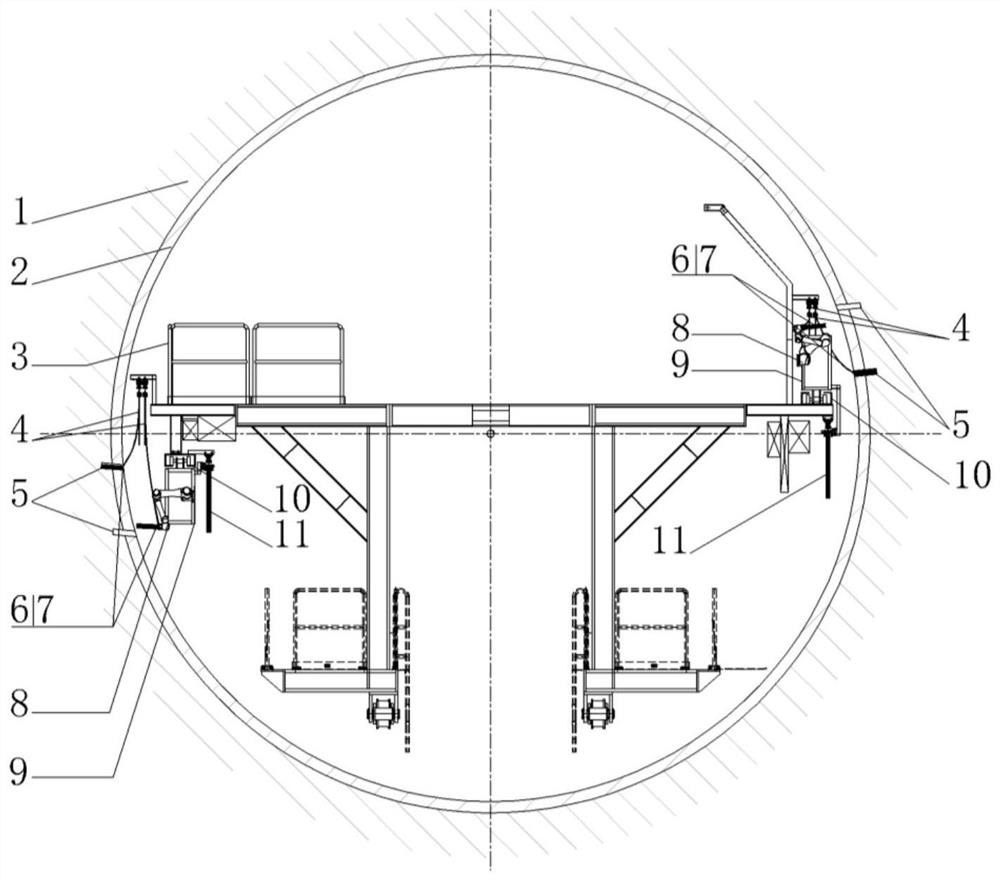

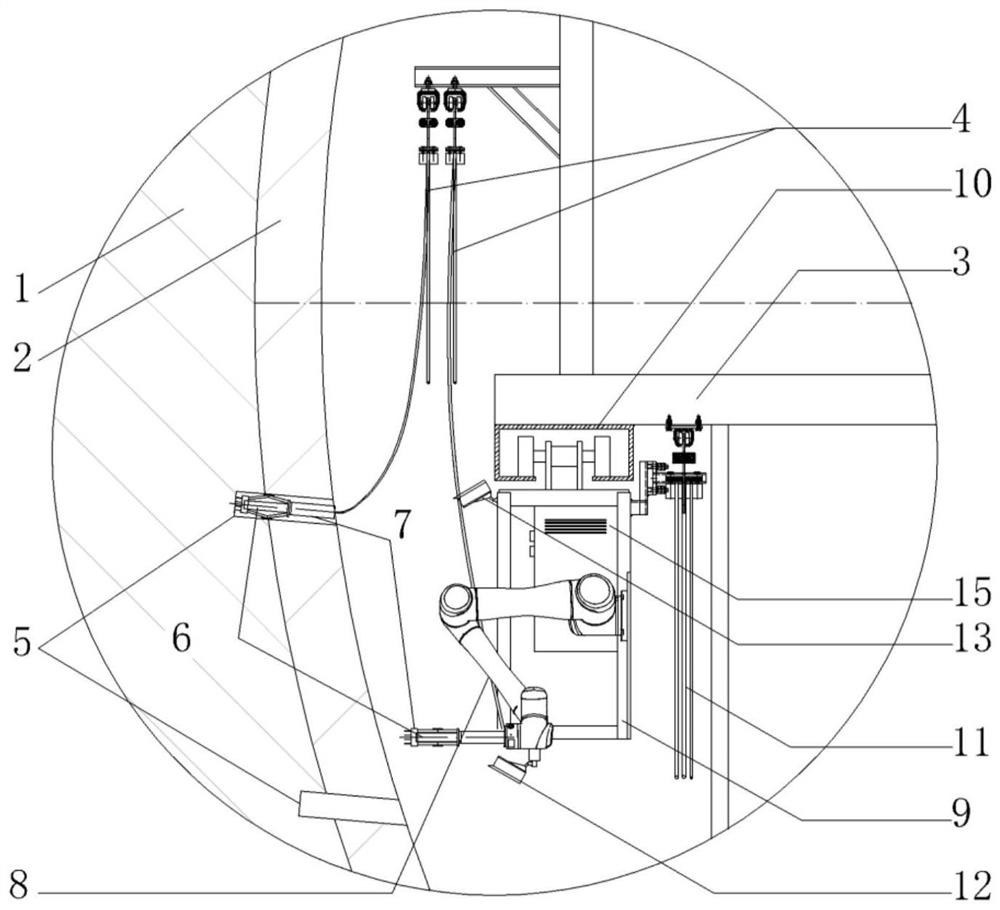

[0047] 1. The equipment layout of the automatic monitoring and intelligent early warning system for rock burst microseism in TBM construction

[0048] like figure 1 , figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com