Controllable separated power device and swing piece manual-automatic integrated actuator

A technology of power device and power input end, applied in the field of mechanical automation, can solve the problems of tooth punching or manual automatic function switching delay, difficult separation or meshing between electromagnetic claw and planetary gear assembly, etc., to achieve smooth switching, low working energy consumption, Space and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

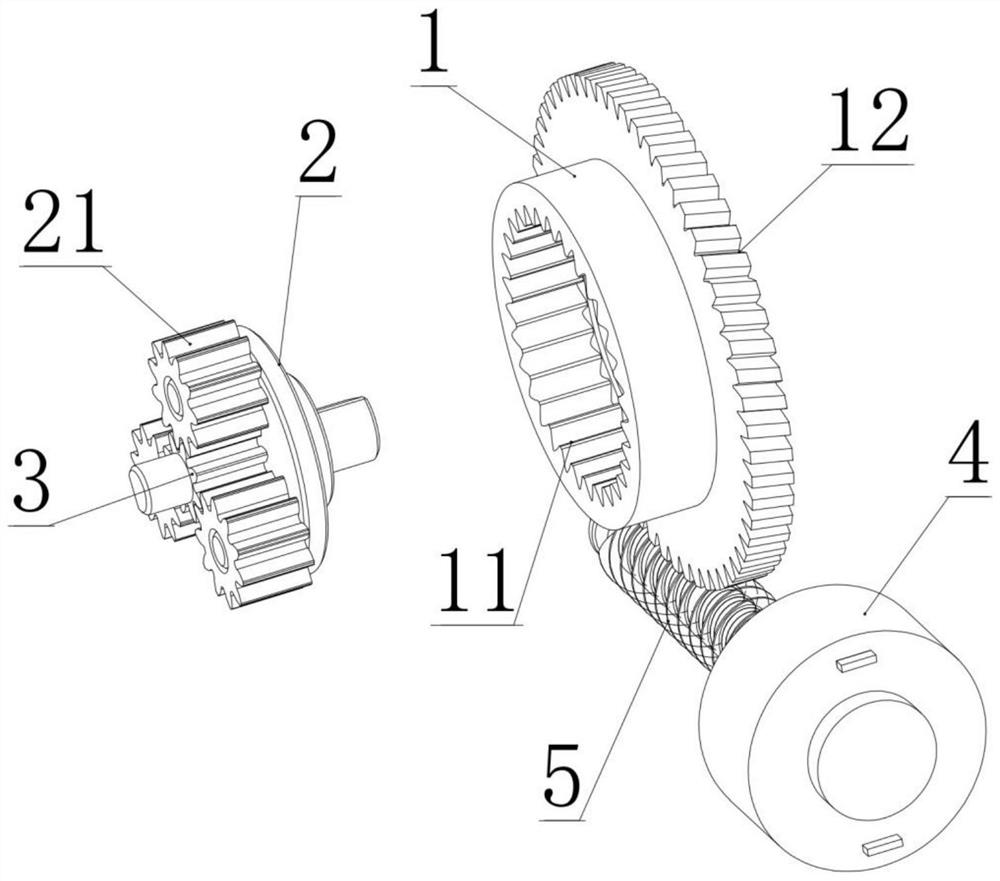

[0029] A controllable separation powerplant such as figure 1 As shown, it includes a ring gear 1, a planetary carrier 2 and a sun gear 3 that are rotatably arranged on the same axis; The inner ring gear part 11 on the inner circumference of the ring gear 1 is meshed, and the sun gear 3 is meshed with the planetary gear 21; The outer ring gear part 12 on the outer circumference of the ring gear 1 is non-self-locking meshing connection; in the planet carrier 2 and the sun gear 3, one end is used as the power input end, the other end is used as the power output end, and the locked-rotor motor 4 is used as the control end to control the ring gear 1. Whether it can rotate freely, so as to controllably switch whether the power input end and the power output end are in a power separation state or a power connection state.

[0030] The tooth shape of the outer ring gear part 12 is helical teeth or worm teeth. In order to ensure the non-self-locking meshing of the locked-rotor worm 5 ...

Embodiment 2

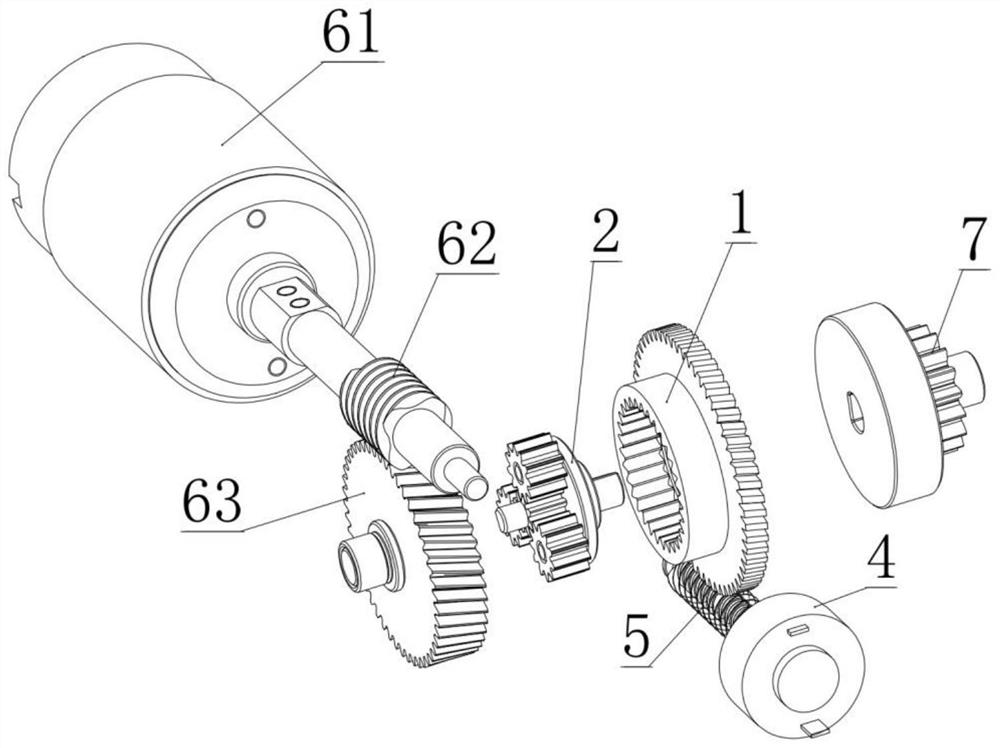

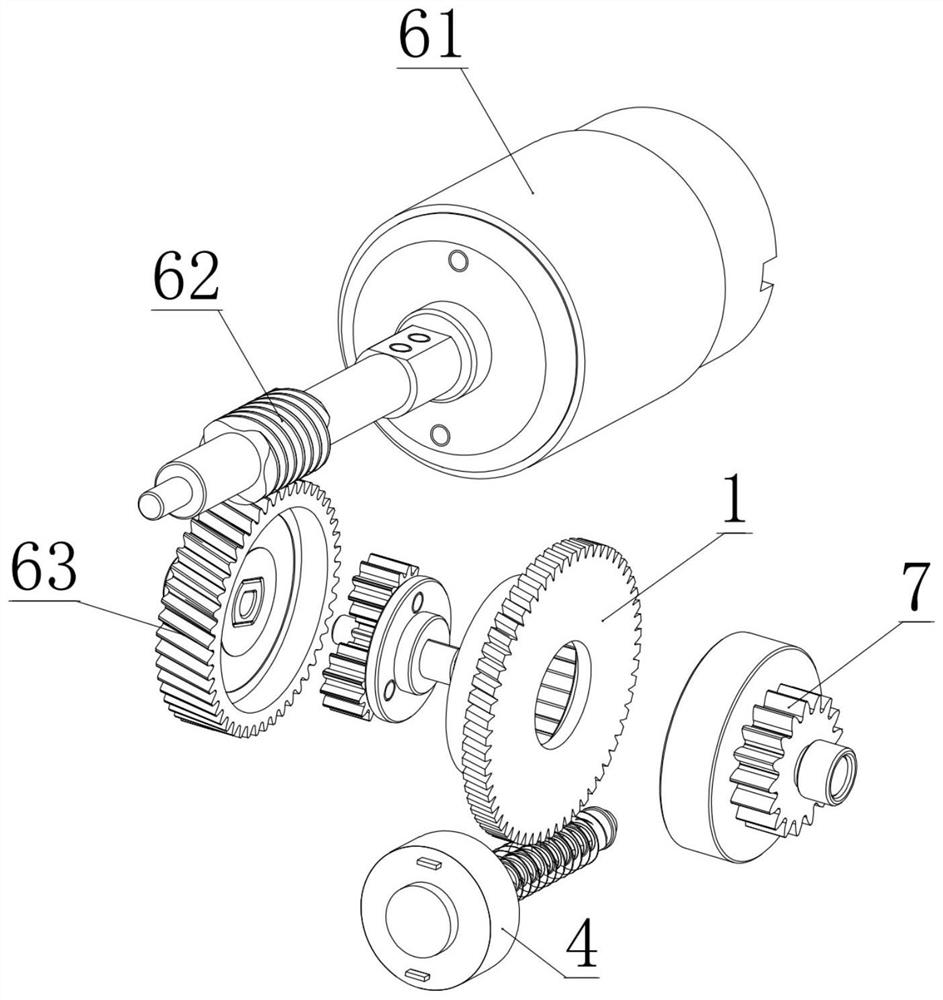

[0036] The controllable separation power plant provided in this embodiment is a further improvement to Embodiment 1, specifically as follows figure 2 , 3 As shown, the sun gear 3 is used as a power input end, and the planet carrier 2 is used as a power output end; a power supply unit is also provided at the power input end to drive the sun gear 3 to rotate. The power supply unit includes a power motor 61 , a power worm 62 driven to rotate by the power motor 61 , and a power gear 63 coaxially connected to the sun gear 3 ; the power worm 62 meshes with the power gear 63 . Among them, the power gear 63 is a worm gear or a helical gear. In addition, the planet carrier 2 is also coaxially connected with a power output gear 7 for external power output.

Embodiment 3

[0038] An oscillating piece manual-integrated actuator, such as Figure 4 As shown, it includes the controllable separation power device of Embodiment 2, and also includes an arc-shaped rack 91 and a limit post 92 . The inner side of the arc-shaped rack 91 has a tooth surface and meshes with the power output gear 7; the limit post 92 is arranged on the outer side of the arc-shaped rack 91 and abuts against the arc-shaped rack 91 to ensure that the arc-shaped rack 91 and the power output The gear 7 is meshed; the preferred way is to set a rolling sleeve on the limit post 92 to reduce the frictional force when the arc-shaped rack 91 moves; the power output gear 7 drives the arc-shaped rack 91 between the power output gear 7 and the limiter. move within the gaps between the bit posts 92 .

[0039] The manual-automatic actuator of the swing piece also includes a mounting bracket 93 ; the mounting bracket 93 is hinged on one end of the arc-shaped rack 91 .

[0040] The oscillatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com