Prediction method of starch dosage in hydrotalcite chewable tablet production process

A technology of magnesium carbonate chewable tablet and prediction method, which is applied in measurement devices, suspension and porous material analysis, instruments, etc., can solve problems such as low energy efficiency, improve production energy efficiency, be suitable for large-scale industrial production, accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A kind of prediction method of starch consumption in the production technology of aluminum magnesium carbonate chewable tablet

[0035] Specific steps:

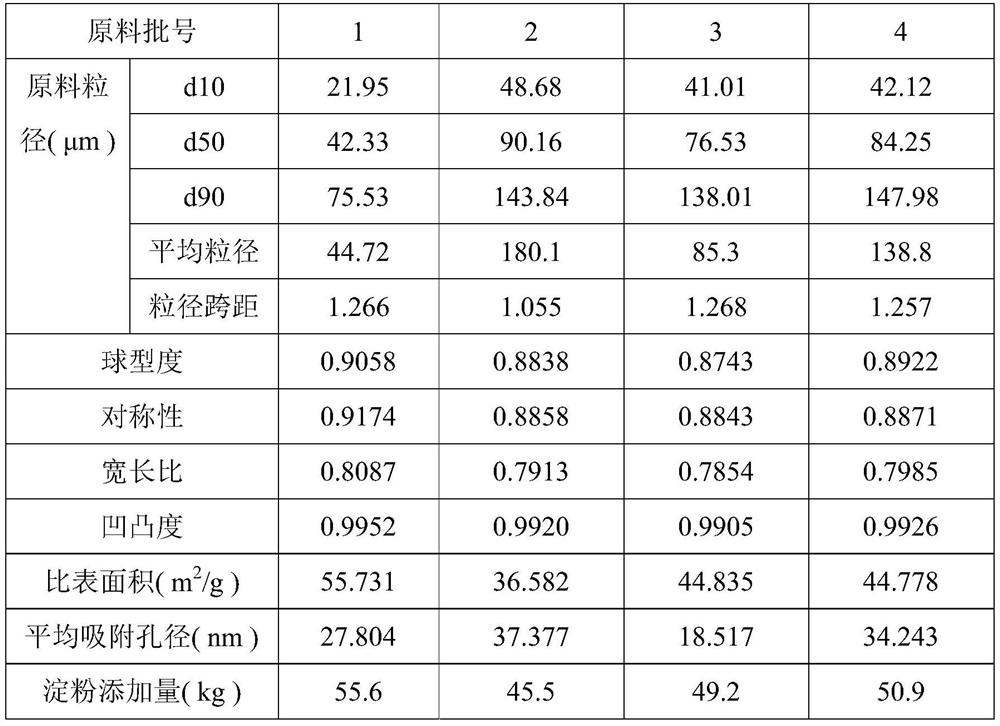

[0036] S1, utilize the detection data (referring to Table 1) of the microstructural properties of the aluminum magnesium carbonate raw material adopted in the historical production process to establish a correlation coefficient for the starch addition, and obtain a starch addition prediction model;

[0037] S2, using Excel to obtain the expression of the prediction model, when the source of the raw material or the batch number changes, the established starch addition amount prediction model is used to predict the starch addition amount used in the process.

[0038] Table 1 Microstructure test data of aluminum magnesium carbonate

[0039]

[0040] Among them, select the specific surface area, particle size span and average adsorption pore size in the microscopic properties of the aluminum magnesium carb...

Embodiment 2

[0054] Embodiment 2 A kind of prediction method of starch consumption in the production technology of aluminum magnesium carbonate chewable tablet

[0055] Use the calculation formula of starch addition amount obtained in Example 1 to predict the starch addition amount of different batches of aluminum magnesium carbonate raw materials, and compare the predicted starch addition amount with the actual starch addition amount. The results are shown in Table 2.

[0056] Table 2 Comparison of predicted starch usage and actual starch usage

[0057] group Raw material 1 Raw material 2 Raw material 3 raw material 4 Predicted amount of starch added (kg) 49.7 51.6 47.0 55.2 Actual starch addition (kg) 50.1 51.3 47.1 54.9 Difference (kg) 0.4 0.3 0.1 0.3 Difference / Actual starch addition (%) 0.80 0.58 0.21 0.55

[0058] As can be seen from the table, the predicted calculation formula of starch addition amount obtained in Example 1 ...

Embodiment 3

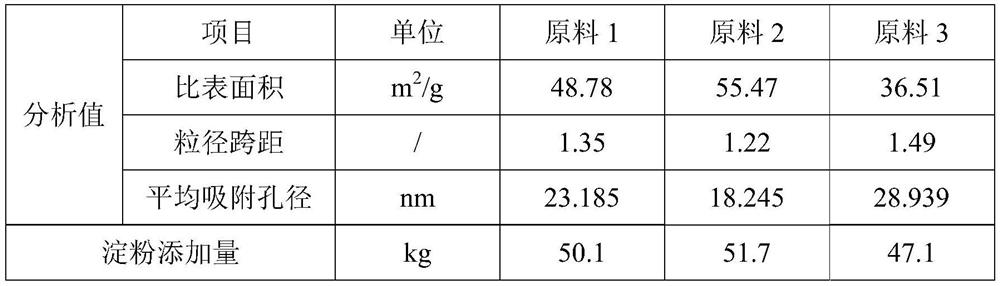

[0059] Embodiment 3 A kind of prediction method of starch consumption in the production technology of aluminum magnesium carbonate chewable tablet

[0060] Using the calculation formula of the starch addition amount obtained in Example 1 (starch addition amount=36.025+0.245×specific surface area+2.608×particle size span-0.06×average adsorption pore size), the required amount of raw materials for three batches of unprocessed aluminum magnesium carbonate is The amount of starch added is predicted, and the results are as follows:

[0061] Table 3 Predicted starch addition by microstructural parameters of raw aluminum magnesium carbonate raw materials

[0062]

[0063] The data was applied to the processing technology of aluminum magnesium carbonate chewable tablets, and on the basis of ensuring the quality of aluminum magnesium carbonate chewable tablets, the preliminary test work was greatly shortened, and the accurate starch addition amount was obtained. In the actual produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com