A method for efficient preparation of pao40 base oil

A base oil and high-viscosity base oil technology, applied in the field of chemical synthesis, to achieve the effects of saving production costs, good lubrication performance, and improving production energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

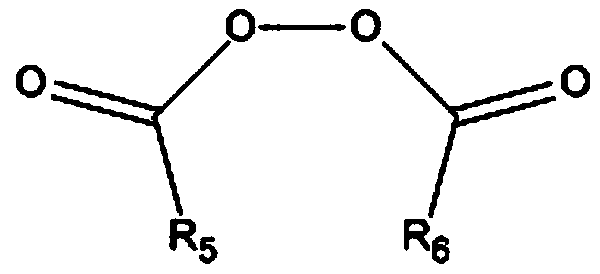

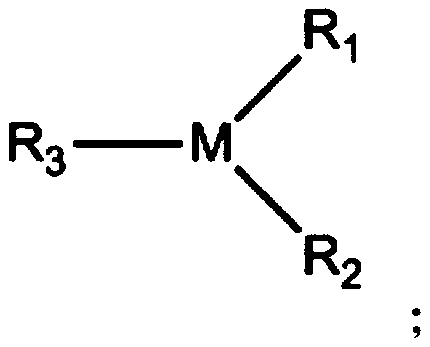

Method used

Image

Examples

Embodiment 1

[0049] Put 150g of aluminum trichloride, 120g of 15% triisobutylaluminum hexane solution, and 5800g of refined waste lubricating oil into the polymerization kettle, adjust the reaction temperature in the kettle to 40°C, and add 35g of benzoyl peroxide; Polymerization reaction, the reaction time is 1h, and a high-viscosity crude product is obtained.

[0050] Part of the catalyst was removed by filtration, washed with 60% sodium hydroxide aqueous solution, and the aluminum trichloride was neutralized until the pH of the solution was neutral, and the remaining was put into a rotary evaporator for vacuum distillation.

[0051] The vacuum distillation product is pressurized and mixed with hydrogen, and directly enters the device equipped with a hydrogenation catalyst. The feed temperature is 260°C, the hydrogen partial pressure is 15MPa, and the volume space velocity is about 0.5h -1 , The volume ratio of hydrogen to oil is 500:1, and the new PAO40 base oil is obtained through hydr...

Embodiment 2

[0053] Put 150g of aluminum trichloride, 25g of triisobutylaluminum, and 6000g of refined waste lubricating oil (low viscosity PAO≈4-6) into the polymerization kettle, adjust the reaction temperature in the kettle to 60°C, and add 25g of benzene peroxide Formyl, a polymerization reaction occurs, the reaction time is 1.5h, and a high-viscosity crude product is obtained.

[0054] Part of the catalyst was removed by filtration, washed with 40% sodium hydroxide aqueous solution, and the aluminum trichloride was neutralized until the pH of the solution was neutral, and the remaining was put into a rotary evaporator for vacuum distillation.

[0055] The vacuum distillation product is pressurized and mixed with hydrogen, and directly enters the device equipped with a hydrogenation catalyst. The feed temperature is 240°C, the hydrogen partial pressure is 18MPa, and the volume space velocity is about 0.5h -1 , The volume ratio of hydrogen to oil is 400:1, and the new PAO45 base oil is ...

Embodiment 3

[0057]Put 150g of aluminum trichloride, 45g of 96% triisobutylaluminum, and 6200g of refined waste lubricating oil (medium viscosity PAO≈10-12) into the polymerization kettle, adjust the reaction temperature in the kettle to 50°C, and add 15g of over Bis(2,4-dichlorobenzoyl) was oxidized, and a polymerization reaction occurred. The reaction time was 0.5h, and a high-viscosity crude product was obtained.

[0058] Part of the catalyst was removed by filtration, washed with 60% sodium hydroxide aqueous solution, and the aluminum trichloride was neutralized until the pH of the solution was neutral, and the remaining was put into a rotary evaporator for vacuum distillation.

[0059] The vacuum distillation product is pressurized and mixed with hydrogen, and directly enters the device equipped with a hydrogenation catalyst. The feed temperature is 260°C, the hydrogen partial pressure is 15MPa, and the volume space velocity is about 0.5h -1 , The volume ratio of hydrogen to oil is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com