Separation gate SiC MOSFET integrated with heterojunction diode and manufacturing method thereof

A diode and heterojunction technology, which is applied in the field of power semiconductor devices, can solve the problems of long forward turn-on voltage drop and reverse recovery time of parasitic body diodes, so as to improve the excessive forward turn-on voltage drop, reduce resistance, and improve switching speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

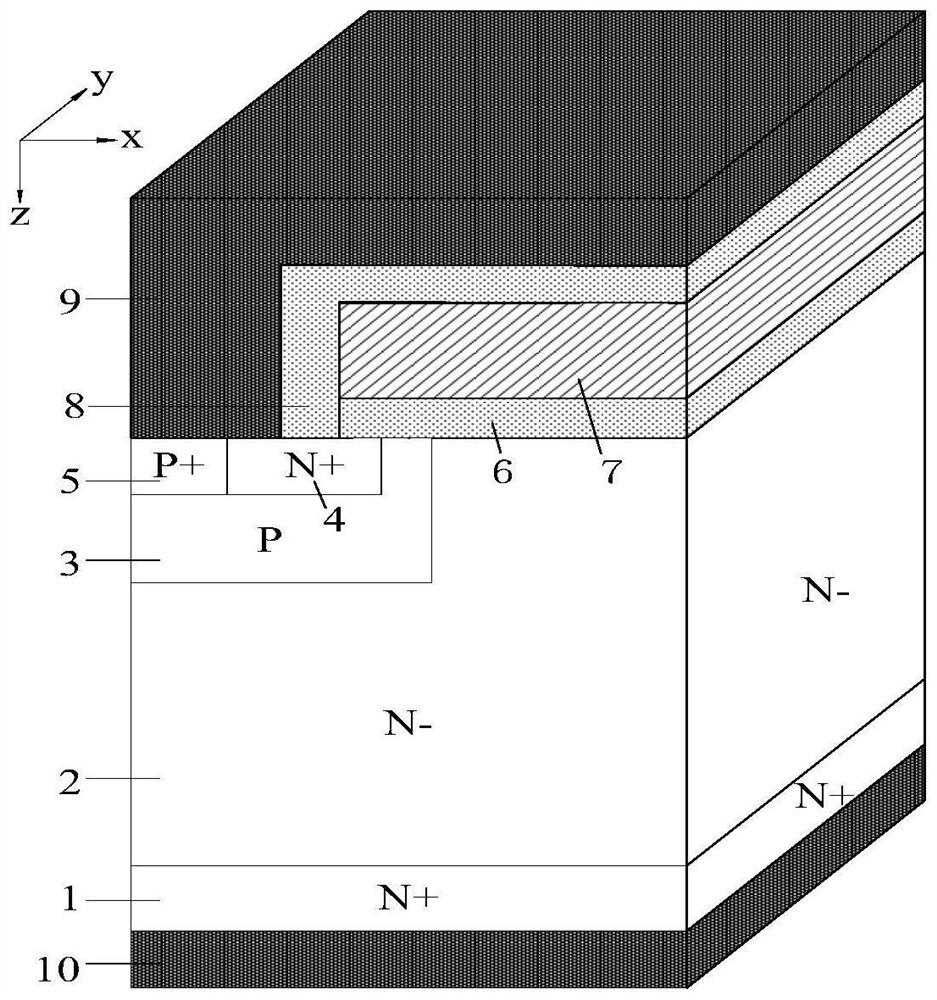

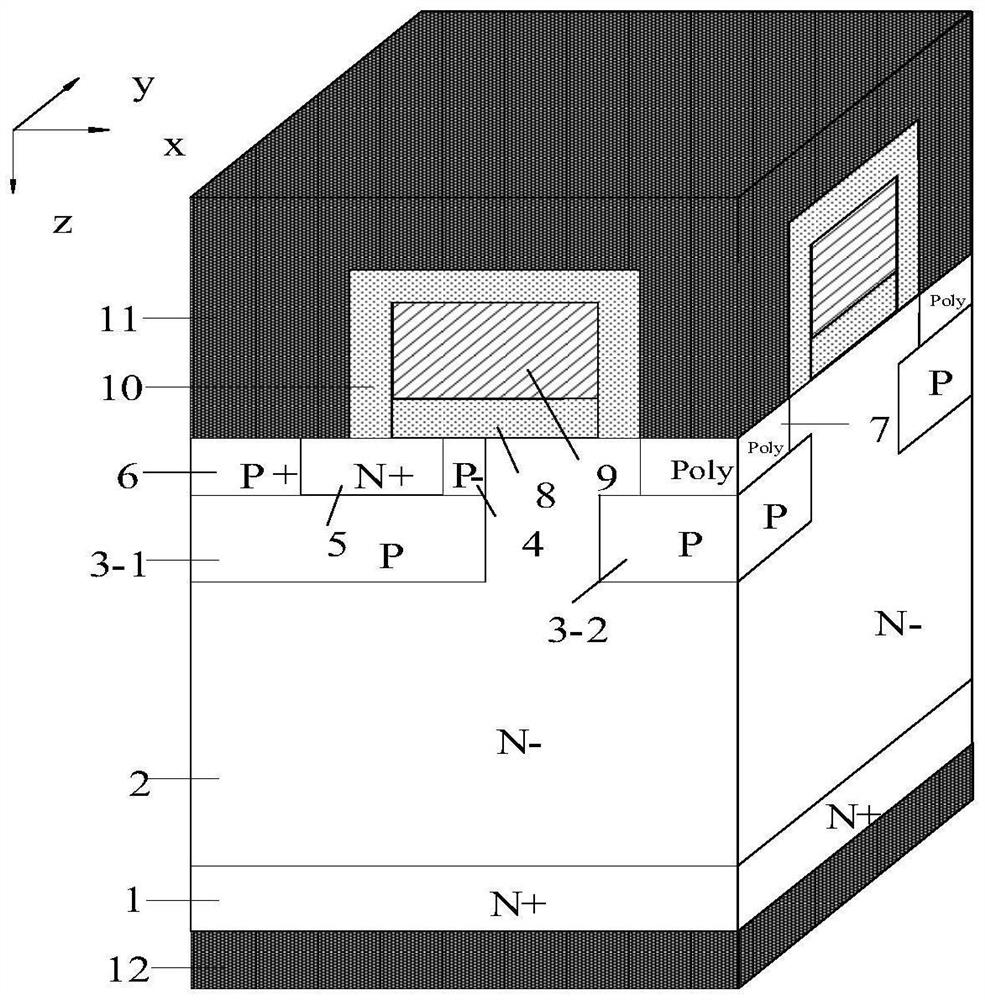

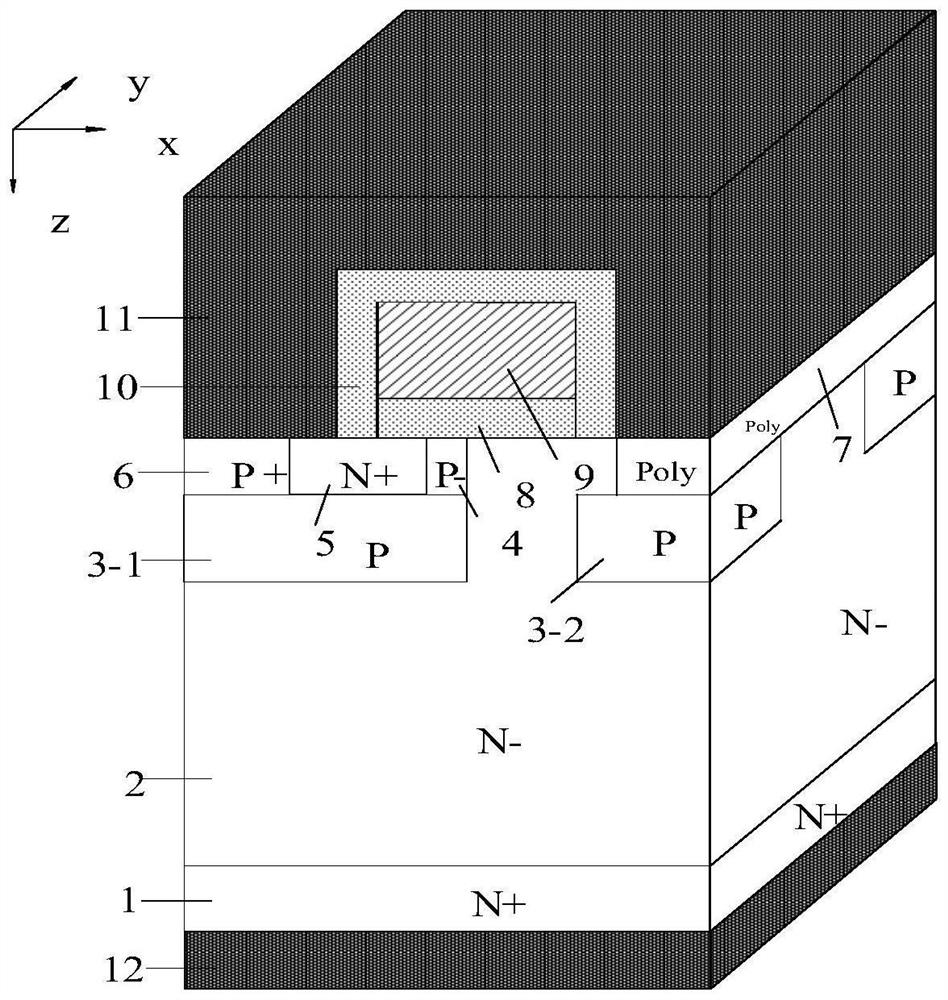

[0045] like figure 2 As shown, the first embodiment of the present invention provides a split-gate SiC MOSFET integrating heterojunction diodes, and the three-dimensional direction of the device is defined in a three-dimensional rectangular coordinate system: the lateral direction of the device is defined as the X-axis direction, and the vertical direction of the device is Y. The axial direction, the longitudinal direction of the device, that is, the third dimensional direction is the Z-axis direction. It is characterized in that its half-cell structure includes: along the Z-axis direction, the back drain metal 12, the N-type substrate layer 1 and the N-type substrate layer 1 and N-drift region 2; along the X-axis direction, the top si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com