Planar high electron mobility transistor

A high electron mobility, transistor technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of high specific on-resistance, non-uniformity of normally-off GaN HEMTs, etc., to reduce energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

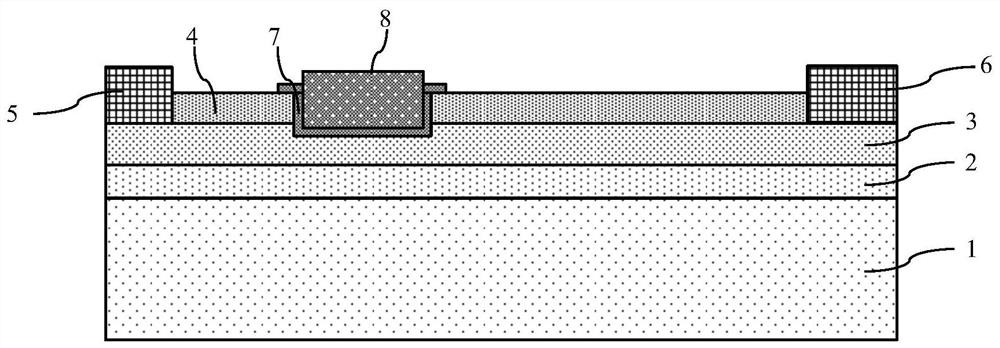

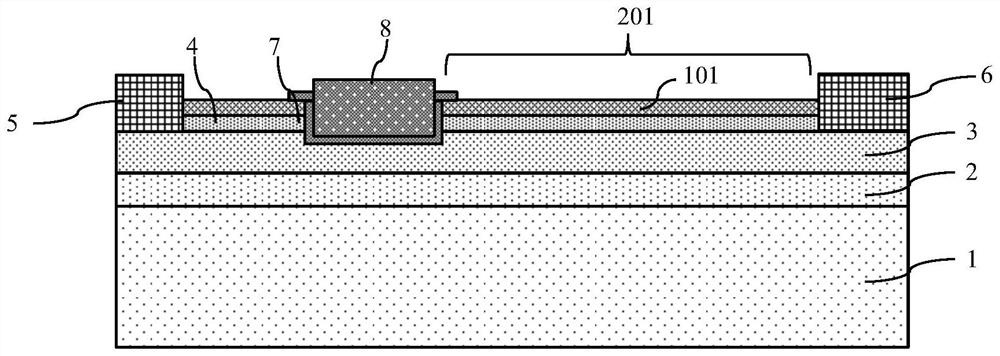

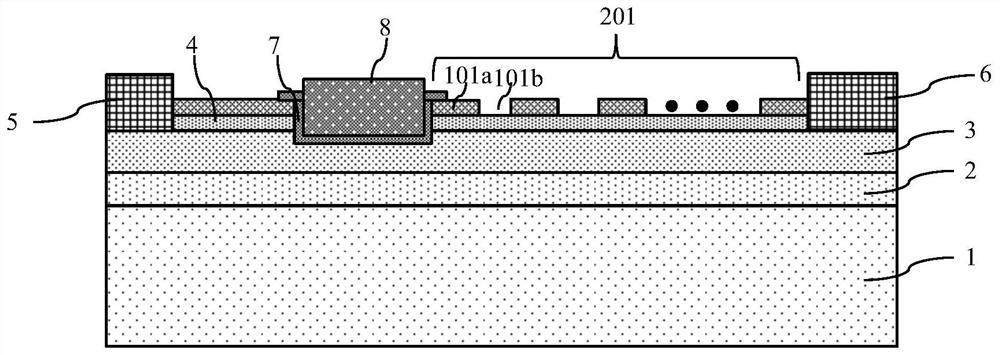

[0062] The first embodiment of the present invention is a planar high electron mobility transistor:

[0063] like figure 1 As shown, it is a schematic structural diagram of the planar high electron mobility transistor according to the first embodiment of the present invention; the device unit of the planar high electron mobility transistor according to the first embodiment of the present invention includes:

[0064] The first semiconductor epitaxial layer 3 and the second semiconductor epitaxial layer 4 formed on the surface of the first semiconductor epitaxial layer 3, the first semiconductor epitaxial layer 3 and the second semiconductor epitaxial layer 4 form a first heterojunction and are A two-dimensional electron gas is formed at the first heterojunction interface.

[0065] The trench gate includes a gate trench, a gate dielectric layer 7 formed on the inner surface of the gate trench, and a gate conductive material layer 8 filling the gate trench.

[0066] The gate tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com