Modified rubber and preparation method thereof

A modified rubber and modified technology, which is applied in the field of modified rubber and its preparation, can solve the problems of poor aging resistance, no obvious improvement in mechanical properties, uneven dispersion of modified nitrile rubber, etc., and achieve good aging resistance , Improve mechanical properties and physical and chemical properties, reduce the effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

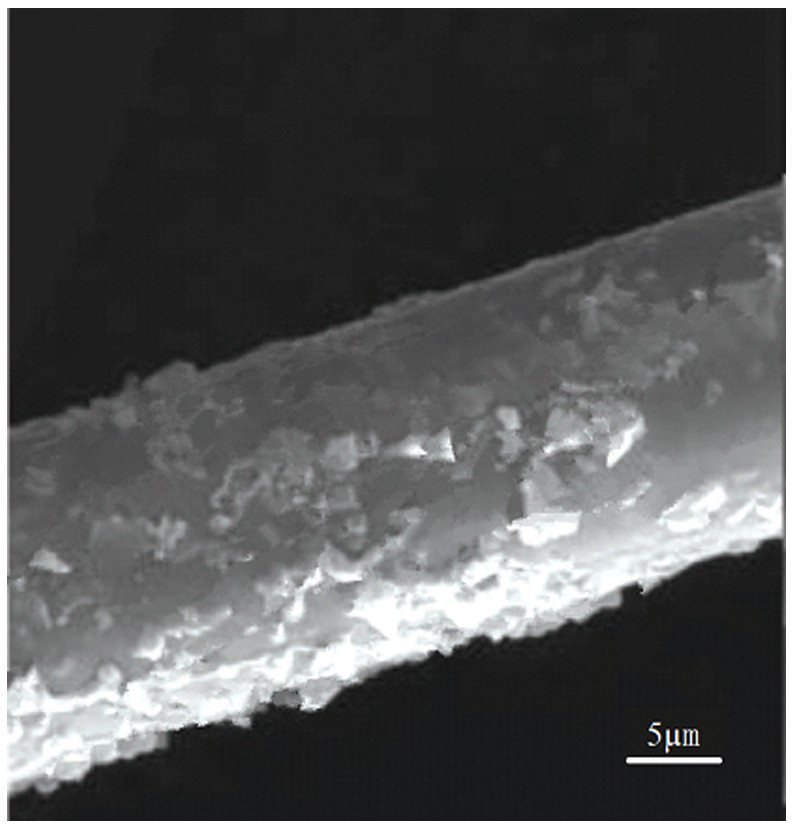

Image

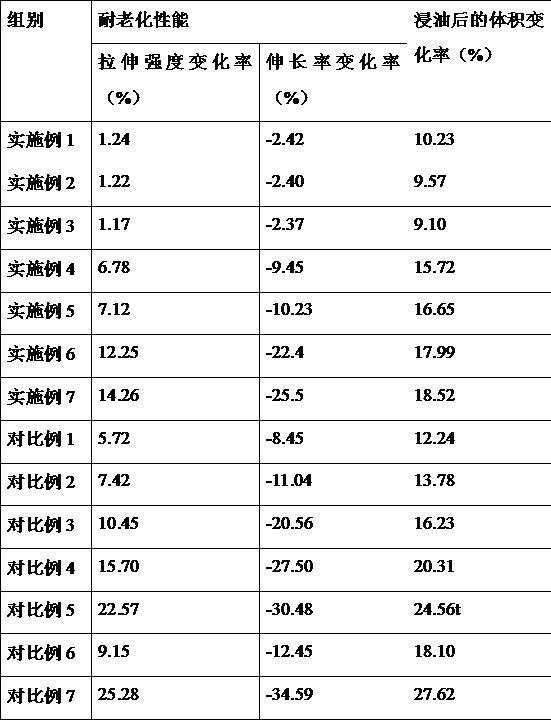

Examples

Embodiment 1

[0043] The present embodiment provides a kind of preparation method of modified rubber, specifically comprises the following steps:

[0044] S1. Preparation of modified graphite: add 100 parts by weight of graphite to 200 parts by weight of 1mol / L NaOH solution, soak for 1 hour, wash, dry at 70°C for 2 hours, ball mill for 2 hours, pass through a 500-mesh sieve, add 1-butyl- 3-Ethylimidazolium chloride, microwave heating to 60°C, stirring for 30min, 1000W ultrasonic for 1h, 3000r / min centrifugation for 15min, washing the solid with deionized water, drying at 70°C for 2h to obtain modified graphite;

[0045] S2. Pretreatment of polyester fibers: 100 parts by weight of polyester fibers are added to 200 parts by weight of ethanol aqueous solution containing 5wt% NaOH, wherein the ethanol content is 30wt%, heated and boiled for 20min, filtered, washed with deionized water, Obtain pretreated polyester fibers;

[0046] S3. Preparation of catalyst solution: Cobalt sulfate is dissolv...

Embodiment 2

[0052] The present embodiment provides a kind of preparation method of modified rubber, specifically comprises the following steps:

[0053] S1. Preparation of modified graphite: add 100 parts by weight of graphite to 200 parts by weight of 2mol / L KOH solution, soak for 2 hours, wash, dry at 70°C for 2 hours, ball mill for 4 hours, pass through a 700-mesh sieve, add 1-butyl- 3-Ethylimidazolium chloride, microwave heating to 80°C, stirring for 40min, 2000W ultrasonic for 3h, 3000r / min centrifugation for 15min, the solid was washed with deionized water, and dried at 70°C for 2h to obtain modified graphite;

[0054] S2. Pretreatment of polyester fibers: 100 parts by weight of polyester fibers are added to 200 parts by weight of ethanol aqueous solution containing 10wt% KOH, wherein the ethanol content is 50wt%, heated and boiled for 30min, filtered, washed with deionized water, Obtain pretreated polyester fibers;

[0055] S3. Preparation of catalyst solution: Cobalt bromide is d...

Embodiment 3

[0061] The present embodiment provides a kind of preparation method of modified rubber, specifically comprises the following steps:

[0062] S1. Preparation of modified graphite: Add 100 parts by weight of graphite into 200 parts by weight of 1.5mol / L NaOH solution, soak for 1.5 hours, wash, dry at 70°C for 2 hours, ball mill for 3 hours, pass through a 600-mesh sieve, and add 1-butyl Base-3-ethylimidazolium chloride, microwave heating to 70°C, stir for 35min, 1500W ultrasonic for 3h, 3000r / min centrifuge for 15min, wash the solid with deionized water, dry at 70°C for 2h to obtain modified graphite;

[0063]S2. Pretreatment of polyester fibers: 100 parts by weight of polyester fibers are added to 200 parts by weight of ethanol aqueous solution containing 7wt% NaOH, wherein the ethanol content is 40wt%, heated and boiled for 25min, filtered, washed with deionized water, Obtain pretreated polyester fibers;

[0064] S3. Preparation of catalyst solution: cobalt chloride is dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com