Temperature-sensitive composition as well as preparation method and application thereof

A composition, temperature-sensitive technology, applied in the direction of pigment paste, etc., can solve the problems of limited use range, opacity, poor aging resistance, etc., and achieve the effects of increasing hydrophilicity, improving permeability, and having little effect on lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

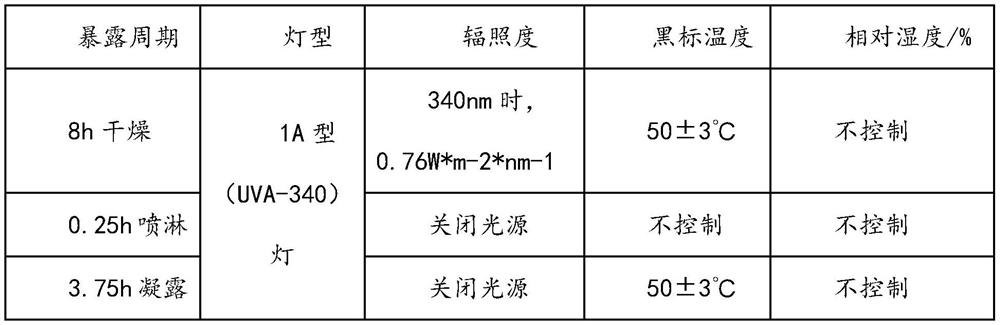

Image

Examples

Embodiment 1

[0022] Weigh 10g iron yellow (particle size 800nm), 0.1gNP-10, 0.2g lauric acid, 30g deionized water, 0.05g sodium dodecyl sulfate in a ball milling jar, and set the ball milling speed to 250r / min. Take it out and place it in a 500ml beaker; dissolve 0.5g of methylcellulose in 30g of aqueous solution, after it is completely dissolved, add 0.1g of fumed silica, stir it evenly, pour it into the above 500ml beaker and mix it with the pigments at high speed. Stir at 300r / min, and mix it evenly to obtain iron yellow slurry;

[0023] Weigh 100g of temperature-sensitive aqueous system solution for standby, take 0.2g of the above-mentioned iron yellow slurry, add 1g of deionized water, and place it in an ultrasonic machine for ultrasonic dispersion for 30min; after dispersion, add it to the aqueous system solution under stirring, and stir After 5 minutes, vacuum defoaming; add the initiator azodiisobutylamidine hydrochloride in aqueous solution (the amount added is 0.1‰ of the mass of...

Embodiment 2

[0025] Weigh 10g iron yellow (particle size 800nm), 0.1gNP-10, 0.2g lauric acid, 30g deionized water, and 0.05g sodium dodecyl sulfate in a ball milling jar. The ball milling speed is set to 250r / min. Take it out and place it in a 500ml beaker; dissolve 0.5g of methylcellulose in 30g of aqueous solution, after it is completely dissolved, add 0.1g of fumed silica, stir it evenly, pour it into the above 500ml beaker and mix it with the pigments at high speed. Stir at 300r / min, and mix it evenly to obtain iron yellow slurry;

[0026] Weigh 100g of temperature-sensitive aqueous system solution for standby, take 0.2g of the above-mentioned iron yellow slurry, add 1g of deionized water, and place it in an ultrasonic machine for ultrasonic dispersion for 30min; after dispersion, add it to the aqueous system solution under stirring, and stir After 5 minutes, vacuum defoaming; add the initiator azodicyanovaleric acid of the aqueous solution (the amount added is 0.5‰ of the mass of the ...

Embodiment 3

[0028] Combining the results of case 1 and case 2, using the color standard of case 1, the color paste of case 2 was used to adjust the same color as that of case 1, and the parameter values were compared; 1 For glass of the same color, the visible light transmittances of the glass at 25°C and 47°C are 60.223% and 45.211%, respectively. The permeability of the sample has been significantly improved, and the permeability is more excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com