Scratch-resistant composite UV coating capable of automatically eliminating bubbles and preparation process of scratch-resistant composite UV coating

A technology for eliminating bubbles and preparation process, applied in epoxy resin coatings, coatings, etc., can solve the problems of reduced surface quality, difficult to remove, and bubbles, etc., to reduce surface tension, improve leveling and uniformity, Combining simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

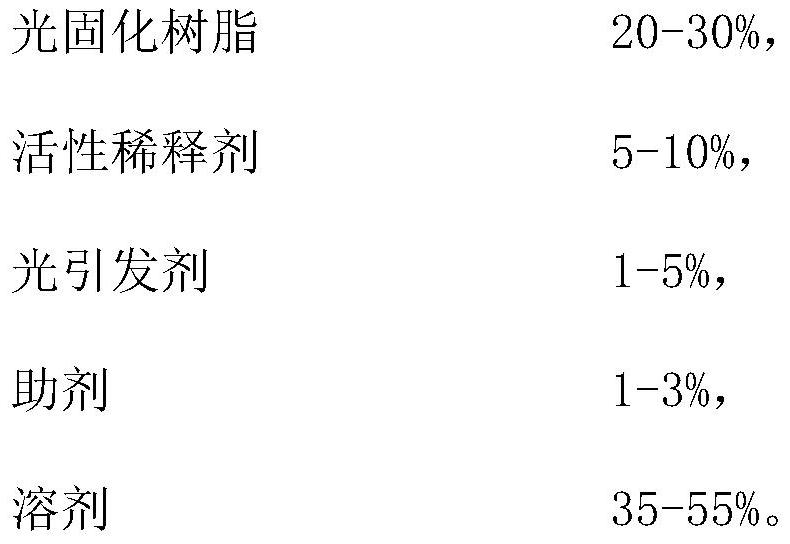

[0026] The weight ratio of each component is:

[0027]

[0028] a. Accurately weigh 21% of bisphenol A type epoxy acrylate, add an appropriate amount of 36% ethyl acetate to dissolve, mix, and mix evenly;

[0029] b. Accurately weigh 6% of propylene glycidyl ether, add an appropriate amount of 36% of ethyl acetate to dissolve, mix, and mix, and then add to a and stir to form a viscous shape;

[0030] c. Accurately weigh 2% benzoin ether, dissolve it with an appropriate amount of 36% ethyl acetate, add it to b and mix evenly with high-speed stirring for 1.5h until it becomes sticky;

[0031] d. Accurately weigh 2% benzoin ether, dissolve it with an appropriate amount of 36% ethyl acetate, and add it to c, mix and stir evenly;

[0032] e. Add the remaining 36% ethyl acetate into d, stir at a high speed and evenly mix to obtain the coating.

Embodiment 2

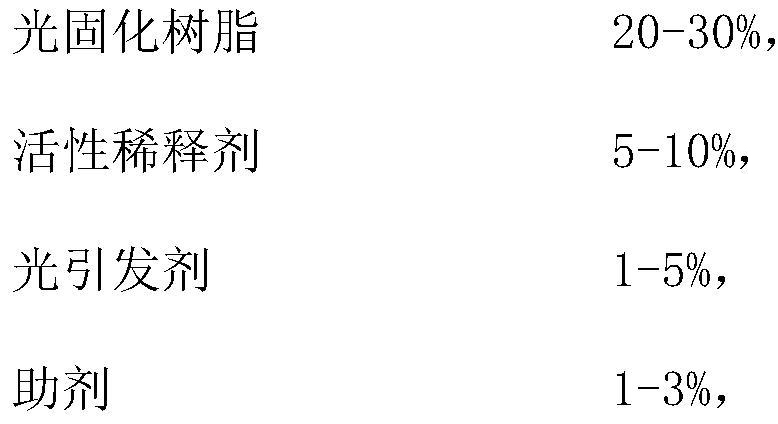

[0034] The weight ratio of each component is:

[0035]

[0036] a. Accurately weigh 22% of bisphenol A type epoxy acrylate, add an appropriate amount of 36% of ethyl acetate to dissolve, mix, and mix evenly;

[0037] b. Accurately weigh 7% of propenyl glycidyl ether, add an appropriate amount of 36% of ethyl acetate to dissolve, mix and mix evenly, and add to a and stir to form a viscous shape;

[0038] c. Accurately weigh 3% benzoin ether, dissolve it with an appropriate amount of 36% ethyl acetate, and add it to b and mix evenly with high-speed stirring for 1.5h until it becomes viscous;

[0039] d. Accurately weigh 3% benzoin ether, dissolve it with an appropriate amount of 36% ethyl acetate, and add it to c, mix and stir evenly;

[0040] e. Add the remaining 37% ethyl acetate into d, stir at a high speed and evenly mix to obtain the coating.

Embodiment 3

[0042] The weight ratio of each component is:

[0043]

[0044] a. Accurately weigh 22% of bisphenol A type epoxy acrylate, add an appropriate amount of 36% of ethyl acetate to dissolve, mix, and mix evenly;

[0045] b. Accurately weigh 7% of propenyl glycidyl ether, add an appropriate amount of 36% of ethyl acetate to dissolve, mix and mix evenly, and add to a and stir to form a viscous shape;

[0046] c. Accurately weigh 3% benzoin ether, dissolve it with an appropriate amount of 36% ethyl acetate, and add it to b and mix evenly with high-speed stirring for 1.5h until it becomes viscous;

[0047] d. Accurately weigh 3% benzoin ether, dissolve it with an appropriate amount of 36% ethyl acetate, and add it to c, mix and stir evenly;

[0048] e. Add the remaining 37% ethyl acetate into d, stir at a high speed and evenly mix to obtain the coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com