Composition for removing corrosion on surface of aluminum alloy as well as preparation method and application of composition

A technology of aluminum alloy surface and composition, which is applied in the field of composition for removing corrosion of aluminum alloy surface and its preparation field, can solve the problems of affecting the health of operators and generating strong acid mist, etc., achieves good effect, is easy to recycle and clean up, and spreads small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

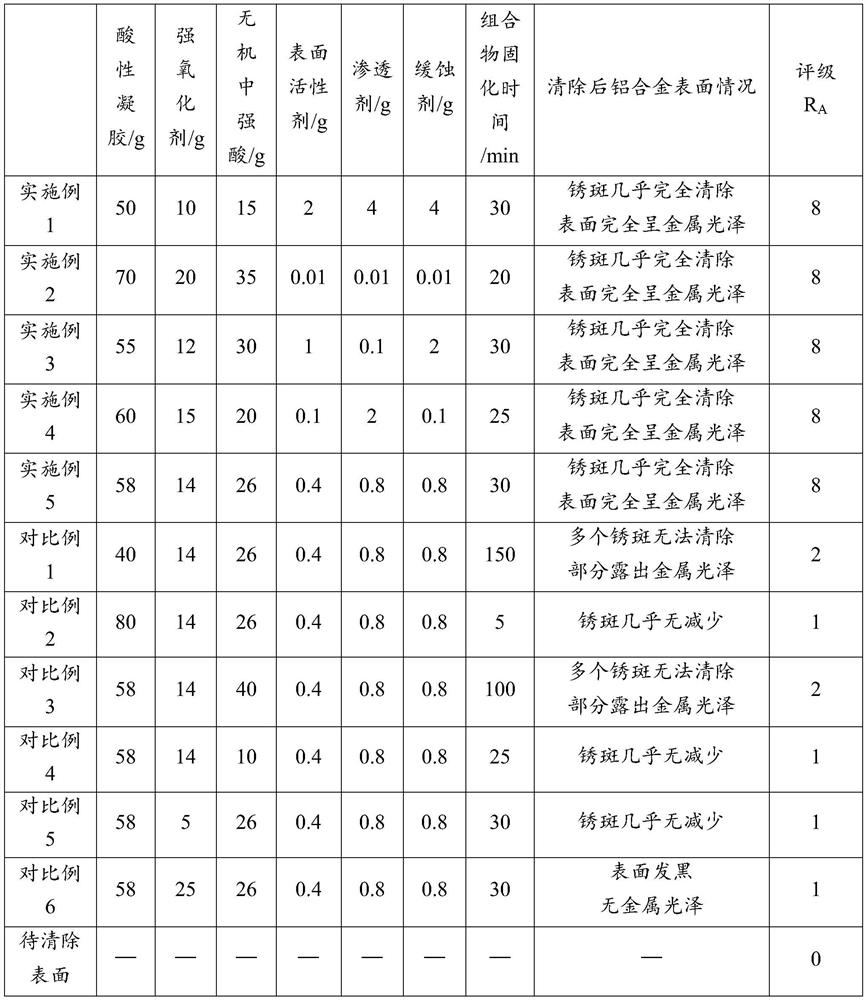

Embodiment 1

[0027] A composition for removing corrosion on aluminum alloy surfaces, comprising: 50g of acidic silica sol, 10g of sodium dichromate, 15g of phosphoric acid, 2g of stearic acid, 4g of fatty alcohol polyoxyethylene ether, and 4g of hexamethylenetetramine.

[0028] The method for preparing the above-mentioned composition for removing corrosion on the surface of an aluminum alloy, comprising:

[0029] (1) stirring and heating each component of the present embodiment under the condition of 120 ° C to form a viscose composition;

[0030] (2) cooling the viscose composition to form a solid composition;

[0031] (3) stirring the solid composition to a fluid viscose state to form a composition for removing corrosion on the surface of an aluminum alloy.

Embodiment 2

[0033] A composition for removing corrosion on the surface of an aluminum alloy, comprising: 70 g of acidic silica sol, 20 g of potassium permanganate, 35 g of phosphoric acid, 0.01 g of sodium dodecylbenzene sulfonate, 0.01 g of fatty alcohol polyoxyethylene ether, water-soluble Benzyltriazole 0.01g.

[0034] The method for preparing the above-mentioned composition for removing corrosion on the surface of an aluminum alloy, comprising:

[0035] (1) stirring and heating each component of the present embodiment under the condition of 100 ° C to form a viscose composition;

[0036] (2) cooling the viscose composition to form a solid composition;

[0037] (3) stirring the solid composition to a fluid viscose state to form a composition for removing corrosion on the surface of an aluminum alloy.

Embodiment 3

[0039] A composition for removing corrosion on the surface of an aluminum alloy, comprising: 55 g of acidic silica sol, 12 g of potassium permanganate, 30 g of phosphoric acid, 1 g of stearic acid, 0.1 g of fatty alcohol polyoxyethylene ether, and 2 g of hexamethylene tetramine .

[0040] The method for preparing the above-mentioned composition for removing corrosion on an aluminum alloy surface, comprising:

[0041] (1) stirring and heating each component of the present embodiment under the condition of 150 ℃ to form a viscose composition;

[0042] (2) cooling the viscose composition to form a solid composition;

[0043] (3) stirring the solid composition to a fluid viscose state to form a composition for removing corrosion on the surface of an aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com