Method for preparing aluminum-scandium-transition metal alloy through consumable cathode molten salt electrolysis

A technology for consumable cathodes and transition metals, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of unavailability, low melting point of aluminum, and preparation of aluminum-scandium alloys, and achieves easy regulation, stable metal alloy composition, and alloy composition. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific preparation process of the present embodiment is as follows:

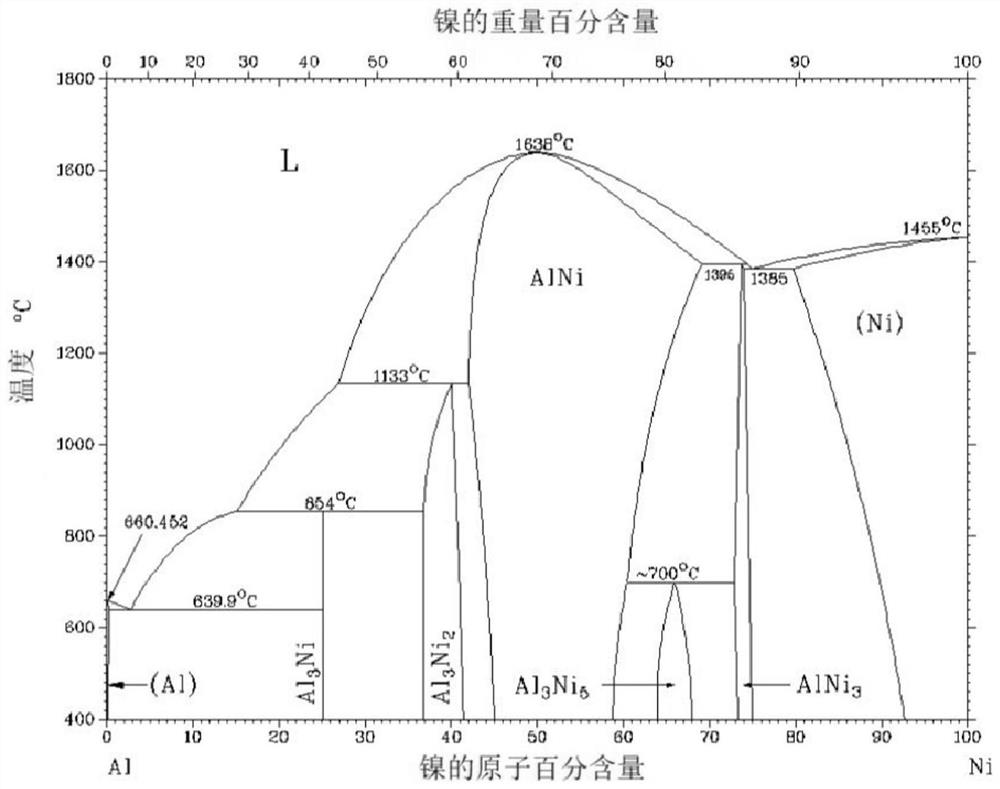

[0033] (1) Preparation of aluminum-nickel alloy consumable cathode. Aluminum and nickel are made into alloy rods, and the content of nickel in the alloy can be 50% to 90% by weight. In this embodiment, an AlNi alloy with a nickel content of 70% is selected, and the melting point of the alloy is 1638 ° C (such as figure 1 shown), the AlNi alloy is made into a cylindrical alloy rod;

[0034] (2) Preparation of aluminum-nickel-scandium alloy by molten salt electrolysis. The AlNi alloy rod is used as a plug-in cathode to prepare metal scandium by molten salt electrolysis with scandium oxide as raw material to form an aluminum-nickel-scandium alloy. The mass ratio of the molten salt system is LiF 20%, and the corresponding scandium fluoride accounts for 80%. ℃, cathode current density 5A / cm 2 ; The formed liquid ternary aluminum-nickel-scandium alloy is dropped from the cathode surface to the tung...

Embodiment 2

[0036] The specific preparation process of the present embodiment is as follows:

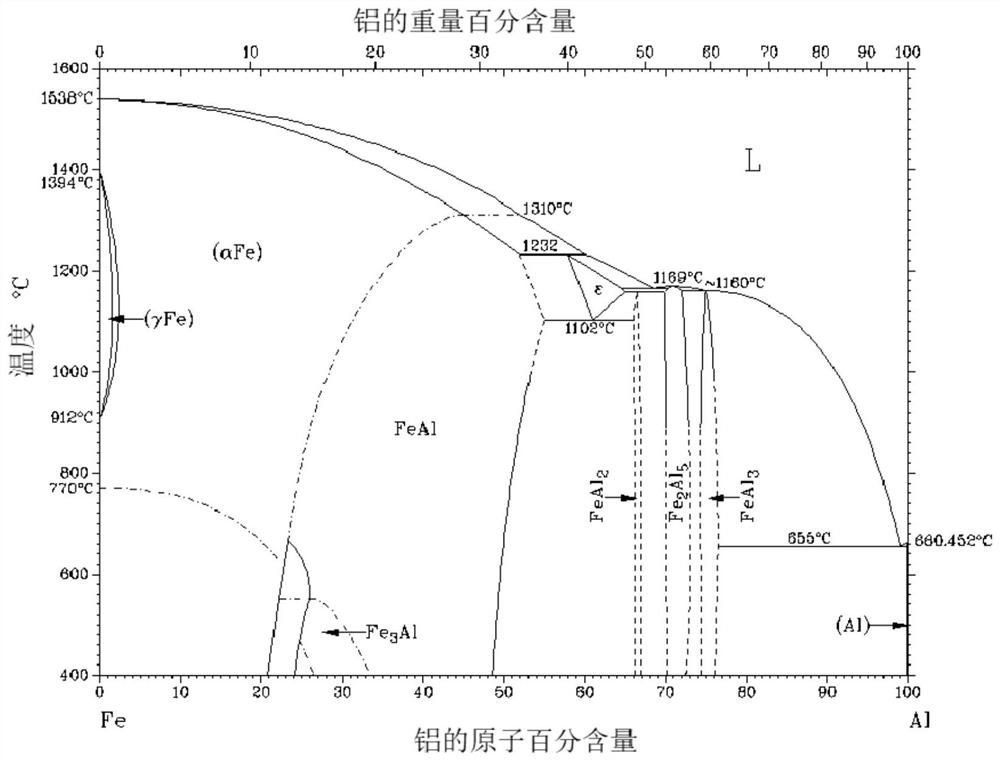

[0037] (1) Preparation of aluminum-iron alloy consumable cathode. Aluminum and iron are made into alloy rods, and the content of iron in the alloy can be 60% to 90% by weight. In this embodiment, an AlFe alloy with a nickel content of 72% is selected, and the alloy melting point is 1310 ° C (such as figure 2 shown), the AlFe alloy was made into a quadrangular prism-shaped alloy rod;

[0038] (2) Preparation of aluminum-iron-scandium alloy by molten salt electrolysis. The AlFe alloy rod is used as a plug-in cathode to prepare metal scandium by molten salt electrolysis with scandium oxide as raw material to form an aluminum-iron-scandium alloy. The molten salt system is LiF 75% by mass, cryolite 10%, CaF 2 5%, the corresponding scandium fluoride accounts for 10%, the electrolysis temperature is 1000℃, and the cathode current density is 7A / cm 2 ; The formed liquid ternary aluminum-iron-scandium...

Embodiment 3

[0040] The specific preparation process of the present embodiment is as follows:

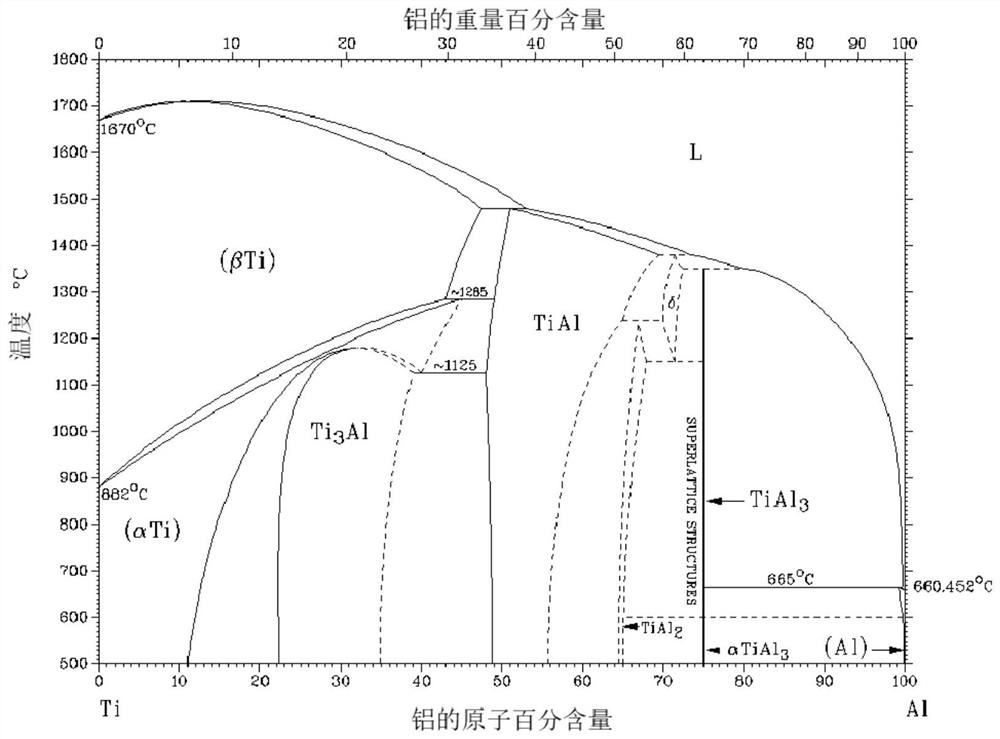

[0041] (1) Preparation of aluminum-titanium alloy consumable cathode. Aluminum and titanium are made into alloy rods, and the content of titanium in the alloy can be 30% to 99% by weight. In this embodiment, TiAl with a titanium content of 38% is selected 3 Alloy, the melting point of the alloy is 1392 ° C (such as image 3 shown), the TiAl 3 The alloy is made into a hexagonal alloy rod;

[0042] (2) Preparation of aluminum-titanium-scandium alloy by molten salt electrolysis. TiAl 3 The alloy rod is used as an upper plug-in cathode to prepare metal scandium by molten salt electrolysis with scandium oxide as raw material to form an aluminum-titanium-scandium alloy. The mass ratio of the molten salt system is LiF15%, KF2%, NaF3%, CaF 2 10%, AlF 3 5%, BaF 2 Scandium fluoride corresponding to 5% accounts for 60%, the electrolysis temperature is 900 ℃, and the cathode current density is 10A / cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com