Waste heat recovery system for silk floss processing and silk floss processing method

A waste heat recovery system and silk floss technology, applied in silk fiber production, mechanical treatment, fiber treatment, etc., can solve the problems of underutilized heat, affecting the service life of silk floss, and consuming a lot of energy, achieving good strength and no peculiar smell , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

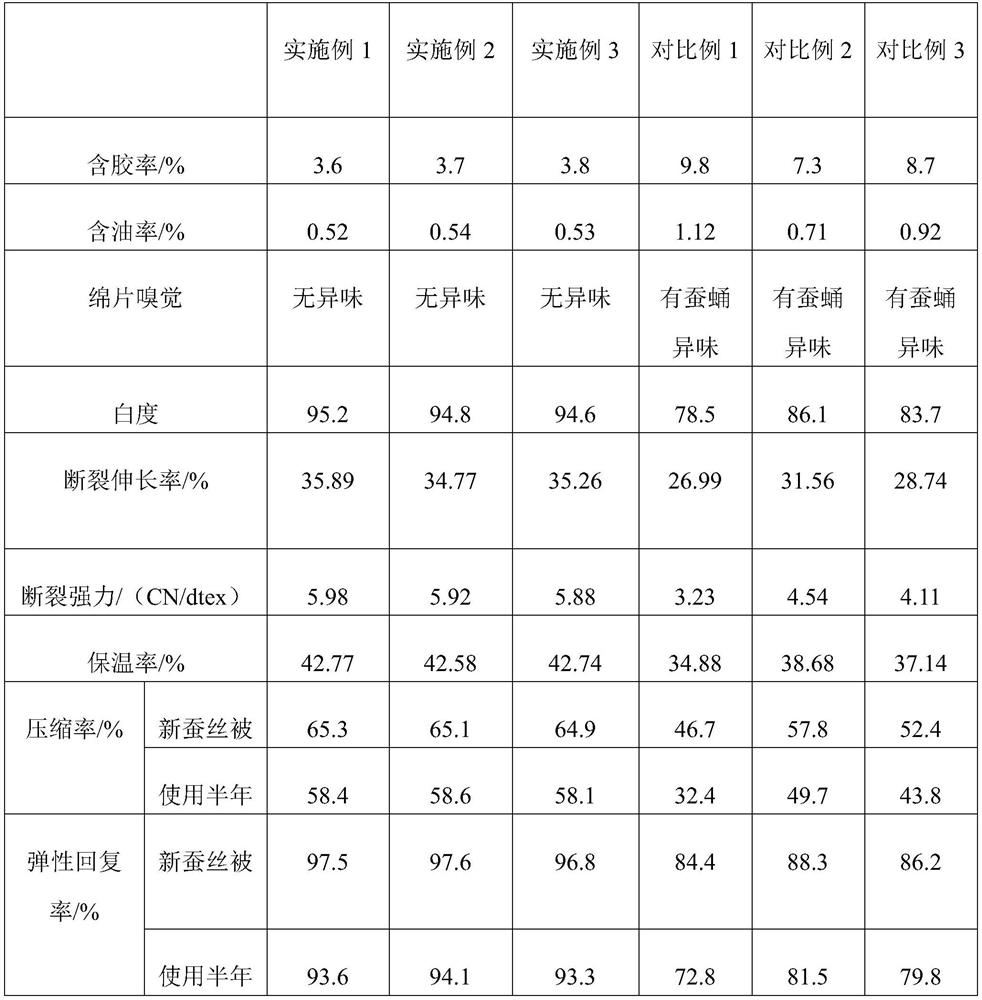

Embodiment 1

[0044] A method for processing silk wool, using the above-mentioned equipment for processing silk wool to process, comprising the following steps:

[0045] (1) Cocoon cooking, after removing impurities from the screened silkworm cocoons, the cocoon cooking is performed in an alkaline solution. Cocoon cooking temperature is 95℃;

[0046] (2) The silkworm cocoons of step (1) are soaked in the treatment agent solution for a period of time, the bath ratio of the silkworm cocoons and the treatment agent solution is 1:20, the soaking time is 3h, and the soaking temperature is 45-50°C.

[0047] The treatment agent includes active enzyme, tea bran solution and surfactant; the active enzyme is neutral protease or neutral lipase, and the mass ratio of the active enzyme to silkworm cocoons is 0.2:1;

[0048] The mass content of the tea bran in the tea bran solution is 10%, and the mass ratio of the tea bran solution to the silkworm cocoon is 13:1;

[0049] The surfactant includes sodiu...

Embodiment 2

[0052] A method for processing silk wool, using the above-mentioned equipment for processing silk wool to process, comprising the following steps:

[0053] (1) Cocoon cooking, after removing impurities from the screened silkworm cocoons, the cocoon cooking is performed in an alkaline solution, the pH value of the alkaline solution used for cocoon cooking is 8.5, and the cocoon cooking time is 60min, Cocoon cooking temperature is 90℃;

[0054] (2) soaking the silkworm cocoons of step (1) in the treatment agent solution for a period of time, the bath ratio of the silkworm cocoons and the treatment agent solution is 1:10, the soaking time is 5h, and the soaking temperature is 45°C.

[0055] The treatment agent includes active enzyme, tea bran solution and surfactant; the active enzyme is neutral protease or neutral lipase, and the mass ratio of the active enzyme to silkworm cocoons is 0.1:1;

[0056] The mass content of the tea bran in the tea bran solution is 5%, and the mass r...

Embodiment 3

[0060] A method for processing silk wool, using the above-mentioned equipment for processing silk wool to process, comprising the following steps:

[0061] (1) Cocoon cooking, after removing impurities from the screened silkworm cocoons, the cocoon cooking is performed in an alkaline solution, the pH value of the alkaline solution used for the cocoon cooking is 9, and the cocoon cooking time is 30min, Cocoon cooking temperature is 100℃;

[0062] (2) soaking the silkworm cocoons of step (1) in the treatment agent solution for a period of time, the bath ratio of the silkworm cocoons and the treatment agent solution is 1:30, the soaking time is 1h, and the soaking temperature is 50°C.

[0063] The treatment agent includes active enzyme, tea bran solution and surfactant; the active enzyme is neutral protease or neutral lipase, and the mass ratio of the active enzyme to silkworm cocoons is 0.3:1;

[0064] The mass content of the tea bran in the tea bran solution is 15%, and the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com