Method for recovering molybdenum and lead from wulfenite

A technology of molybdenum lead ore and lead molybdate, which is applied in the field of lead and molybdenum recovery, can solve the problems of safety and environmental disadvantages, hydrogen sulfide escape, product quality of thiomolybdate discoloration, etc., and achieve the effect of avoiding the leaching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

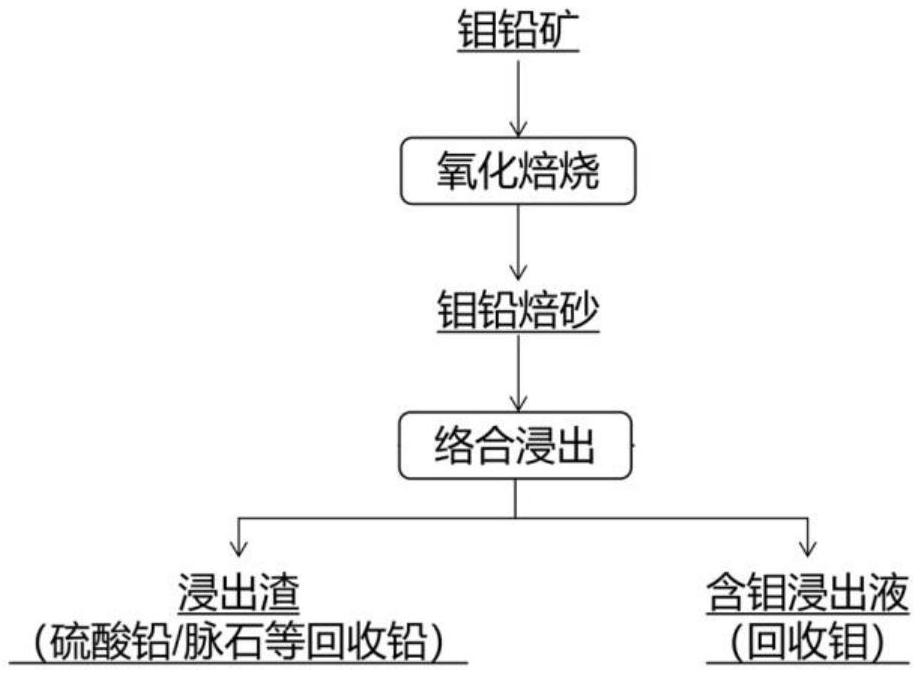

[0078] A specific embodiment of the present invention discloses a method for recovering molybdenum and lead from molybdenum lead ore.

[0079] The lead molybdate calcine obtained by oxidative roasting with molybdenum lead ore as raw material has a molybdenum content of 12.32% and a lead content of 42%.

[0080] Under the normal pressure condition of 100℃, 100g / L sulfuric acid was used for leaching, and phosphoric acid was added as a leaching aid at the same time. The dosage was 1.5 times the total molar amount of sulfuric acid.

[0081] The chemical extraction of molybdenum was carried out by using the extraction agent composed of 30% P507 and 70% sulfonated kerosene. The extraction ratio was O / A=2:1. The extraction method was countercurrent extraction, and the extraction stage was 5. Molybdenum-loaded P507 is obtained by extraction, and the extraction rate of molybdenum can reach 98%.

[0082] The raffinate is recycled to the leaching process after supplementing the sulfuric...

Embodiment 2

[0087] A specific embodiment of the present invention discloses a method for recovering molybdenum and lead from molybdenum lead ore.

[0088] The lead molybdate calcine obtained by oxidative roasting with molybdenum lead ore as raw material has a molybdenum content of 11.32% and a lead content of 40%.

[0089] Under the condition of normal pressure at 80℃, 150g / L sulfuric acid was used for leaching, and phosphoric acid was added as a leaching aid at the same time. The dosage was 1 times the total molar amount of sulfuric acid.

[0090] The chemical extraction of molybdenum was carried out by using an extractant consisting of 40% P204 and 60% sulfonated kerosene. The extraction ratio was O / A=1.2:1, the extraction method was countercurrent extraction, and the number of extraction stages was 8. Molybdenum-loaded P204 is obtained by extraction, and the extraction rate of molybdenum can reach 98.4%.

[0091] The raffinate is recycled to the leaching process after supplementing th...

Embodiment 3

[0096] A specific embodiment of the present invention discloses a method for recovering molybdenum and lead from molybdenum lead ore.

[0097] The lead molybdate calcine obtained by oxidative roasting with molybdenum lead ore as raw material has a molybdenum content of 14.52% and a lead content of 45%.

[0098] Under the condition of normal pressure at 90℃, 200g / L sulfuric acid was used for leaching, and calcium phosphate was added as a leaching aid. The dosage was 0.5 times the total molar amount of sulfuric acid. The leaching time was 5h.

[0099] The chemical extraction of molybdenum was carried out by using an extractant consisting of 10% P204 and 90% sulfonated kerosene. The extraction ratio was O / A=1.5:1. The extraction method was countercurrent extraction, and the number of extraction stages was 8. Molybdenum-loaded P204 is obtained by extraction, and the extraction rate of molybdenum can reach 98.3%.

[0100] The raffinate is recycled to the leaching process after sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com