Titanium-aluminum alloy turbine and preparation method thereof

A titanium-aluminum alloy, turbine technology, applied in mechanical equipment, machines/engines, engine components, etc., can solve the problems of poor strength stability, low strength, unfavorable component reliability, etc., to improve performance and stability, improve blade and cardiac performance for reliable application results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

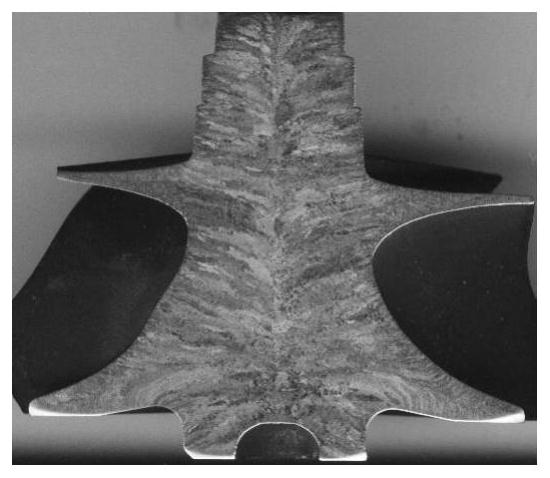

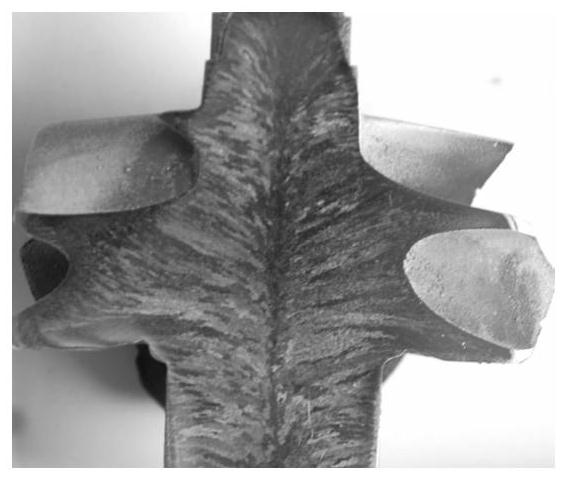

Examples

Embodiment 1

[0029] Alloy Melting:

[0030] The master alloy is prepared according to the theoretical composition (remainder) Ti-46Al-2.0V-1.5Cr-0.5(Zr+Hf+C+W)at%, and is smelted three times in a vacuum induction suspension melting furnace to obtain the master alloy.

[0031] Preparation before pouring:

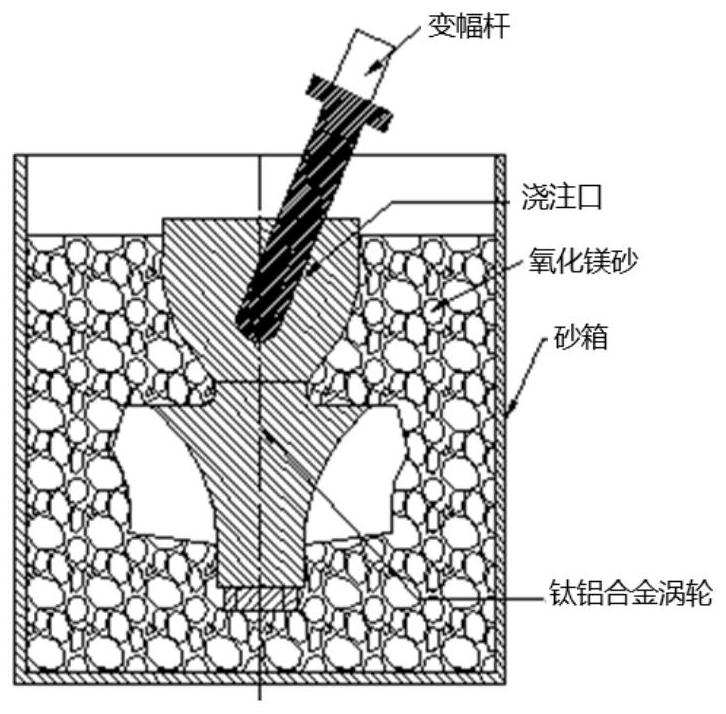

[0032] Put the ceramic mold shell of yttrium oxide surface layer into the sand box, and fill the space between the mold shell and the sand box with refractory sand, as shown in Figure 3, in which magnesia sand is used as an example. The sand box is preheated, the preheating temperature is 600 ℃, and the temperature is kept warm.

[0033] Pouring and sonication:

[0034] The mother alloy is loaded into the crucible, and the ceramic shell flask is placed on the centrifuge plate. After being evacuated for 8 minutes, it is ready for pouring for electro-melting. After the alloy is melted, the smelting power is given to 140KW and kept for 2 minutes, the speed of the centrifuge is started to ...

Embodiment 2

[0038] Alloy Melting:

[0039] The master alloy is prepared according to the theoretical composition (remainder) Ti-45.5Al-2.2V-1.0Cr-0.2(Zr+Hf+C+W)at%, and is smelted three times in a vacuum induction suspension melting furnace to obtain the master alloy.

[0040] Preparation before pouring:

[0041] Put the ceramic mold shell of yttrium oxide surface layer into the sand box, and fill the space between the mold shell and the sand box with refractory sand, as shown in Figure 3, in which magnesia sand is used as an example. The sand box is preheated, the preheating temperature is 600 ℃, and the temperature is kept warm.

[0042] Pouring and sonication:

[0043] The mother alloy is loaded into the crucible, and the ceramic shell flask is placed on the centrifuge plate. After being evacuated for 8 minutes, it is ready for pouring for electro-melting. After the alloy is melted, the smelting power is given to 140KW and kept for 2 minutes, the speed of the centrifuge is started t...

Embodiment 3

[0047] Alloy Melting:

[0048] The master alloy is prepared according to the theoretical composition (remainder) Ti-46.5Al-1.5V-1.6Cr-0.5(Zr+Hf+C+W)at%, and is smelted three times in a vacuum induction suspension melting furnace to obtain the master alloy.

[0049] Preparation before pouring:

[0050] Put the ceramic mold shell of yttrium oxide surface layer into the sand box, and fill the gap between the mold shell and the sand box with refractory sand, as shown in Figure 3. In the figure, magnesia sand is used as an example. The sand box is preheated, the preheating temperature is 600 ℃, and the temperature is kept warm.

[0051] Pouring and sonication:

[0052] The mother alloy is loaded into the crucible, and the ceramic shell flask is placed on the centrifugal disc. After 8 minutes of evacuation, it is ready for pouring for electro-melting. After the alloy is melted, the smelting power is given to 140KW and kept for 2 minutes, the speed of the centrifuge is started to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com