Air cushion type headbox air flow control system adopting high-pressure fan to blow air

A high-pressure fan and air flow technology, which is applied in pump control, mechanical equipment, non-variable pumps, etc., can solve the problems of Roots fans with high noise, heavy maintenance, and environmental pollution, and reduce operating noise and maintenance Cost, operation and maintenance-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

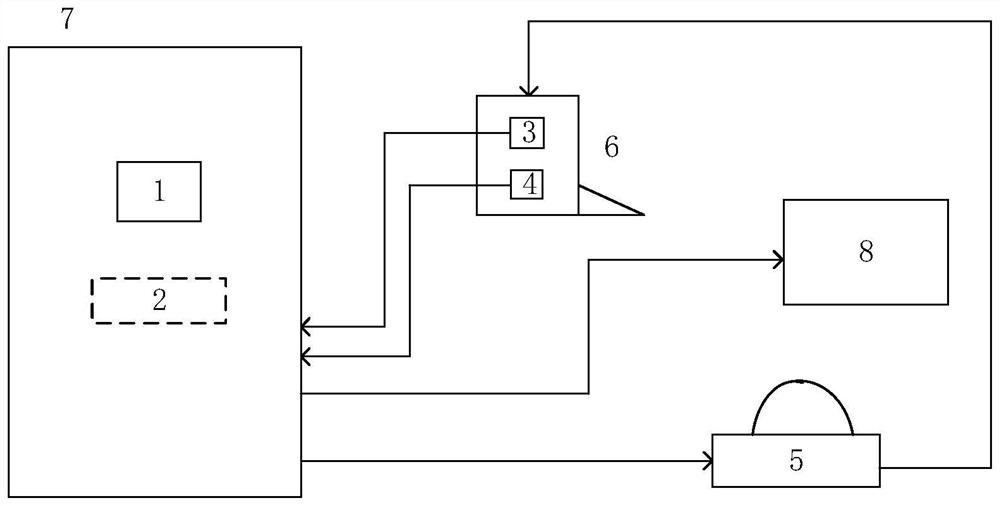

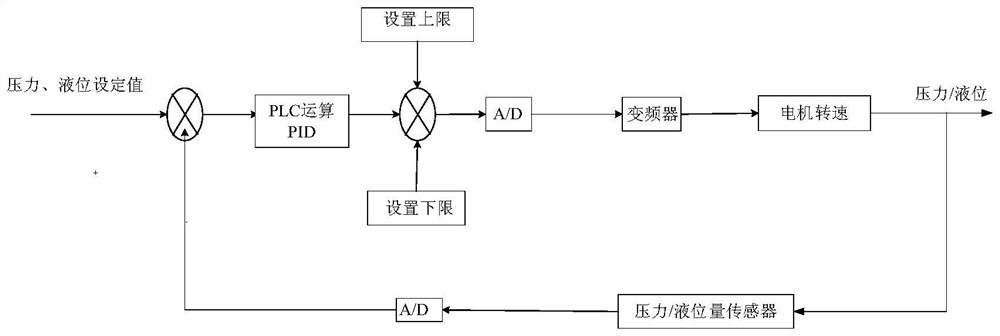

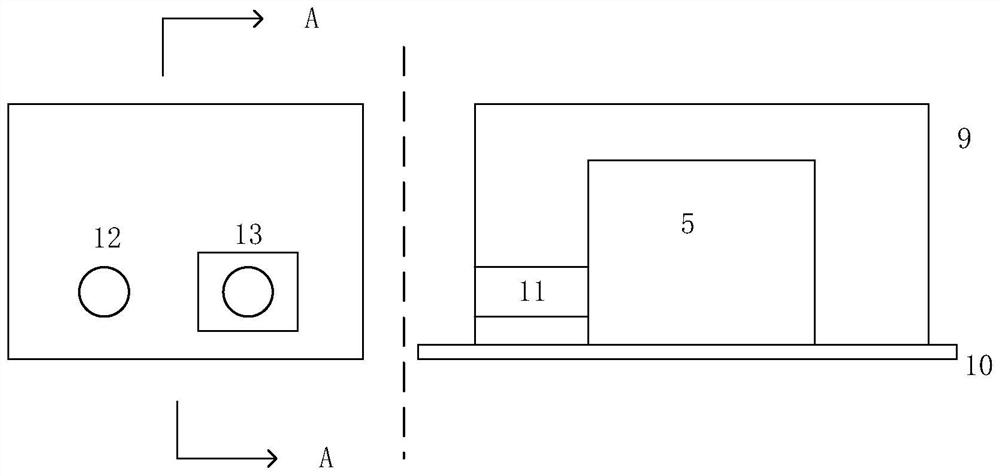

[0029] see figure 1, including the control cabinet 7, the display, operation, and control integrated machine 1 is installed on the door of the control cabinet 7, and the PLC controller 2 is installed in the control cabinet. The display, operation, and control integrated machine 1 and the PLC controller 2 pass through the Ethernet port Connection, the liquid level pressure sensor 1 3 and the liquid level pressure sensor 2 4 on the headbox 6 are respectively connected with the PLC controller 2, the high-pressure fan 5 is connected with the PLC controller 2, and the frequency conversion governor of the high-pressure fan 5 is arranged in the control cabinet. 7, the high-pressure fan 5 is connected with the headbox 6, and the sizing pump motor and the frequency converter 8 are connected with the PLC controller 2. After the system is powered on, first set the liquid level and total pressure to be controlled on the integrated operation display screen, and then start the sizing pump m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com