Polymer stretching and mass transfer integrated overspeed dissolving device and dissolving method thereof

A dissolving device and polymer technology, applied to chemical instruments and methods, dissolving, mixers with rotating stirring devices, etc., can solve the problems of solution viscosity reduction, clogging, unsatisfactory, etc., and achieve large processing capacity and dispensing efficiency Improvement, the effect that setting is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

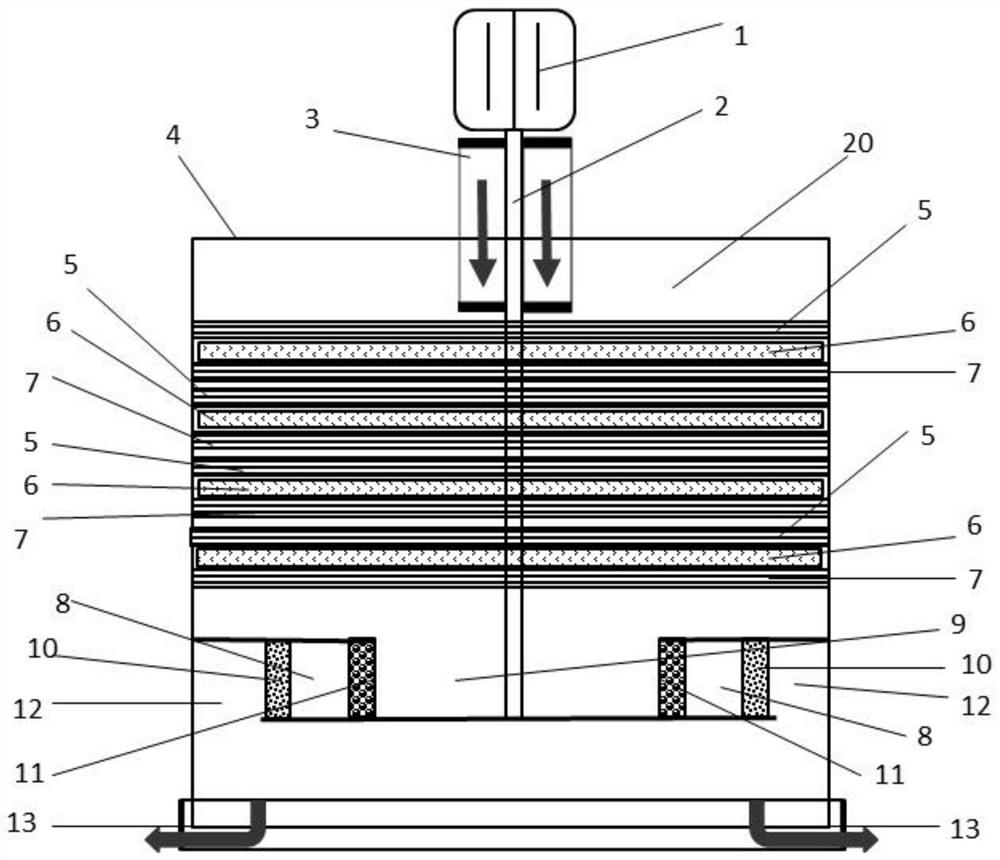

[0029] The embodiment is mainly based on the technical solution that the stretching unit is 4 stretching repeating units connected in series, that is, the number of repeating units n is 4, and the principles of other numbers of stretching repeating units are similar, and will not be repeated.

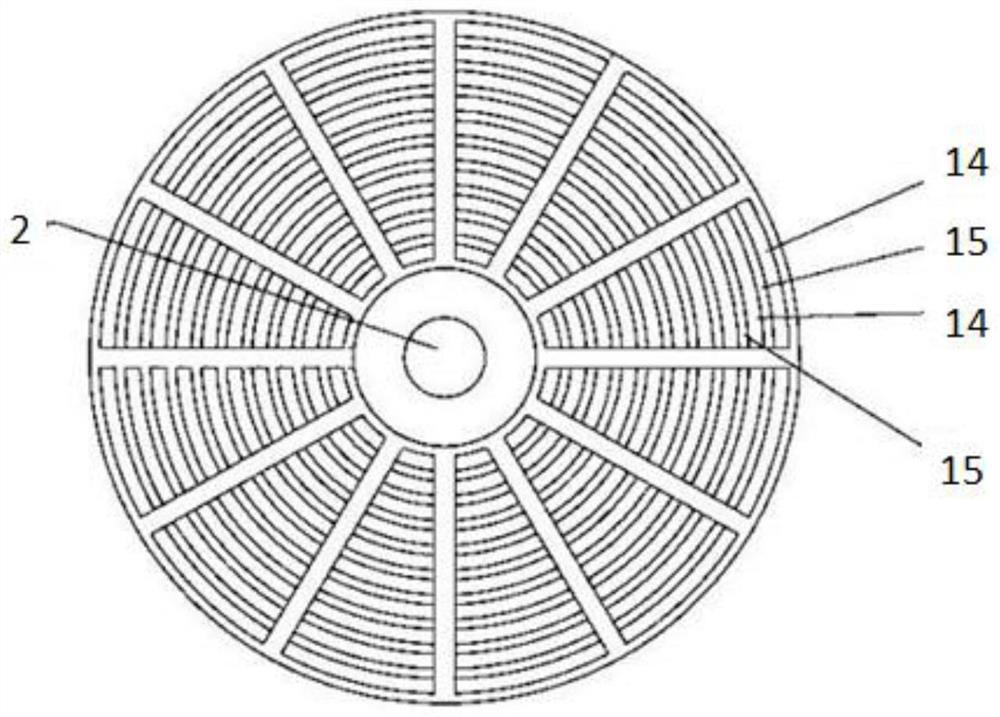

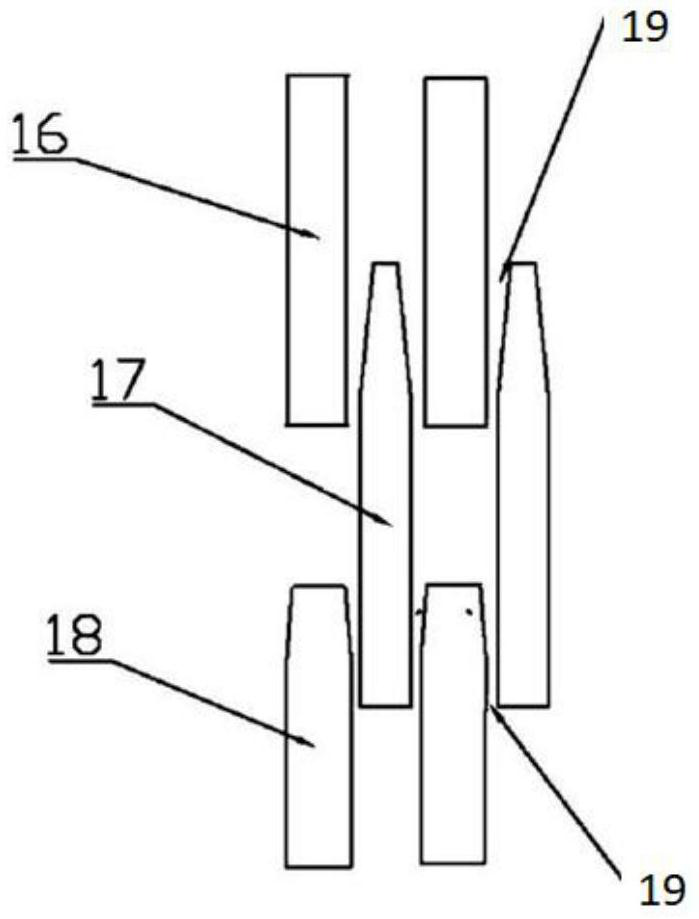

[0030] from figure 1 It can be seen that the integrated ultra-fast dissolving device for polymer stretching and mass transfer is composed of a liquid storage chamber 20, a stretching repeating unit and a mass transfer unit. The movable toothed plate 6 and the lower fixed toothed plate 7 are composed. The upper fixed toothed plate 5 and the lower fixed toothed plate 7 are fixed on the liquid storage chamber 20 or on the device casing 4. The upper fixed toothed plate 5 and the lower fixed toothed plate 7 are close to the moving plate. The surface of the toothed plate 6 adopts a short tooth 14 structure, and evenly engages with the short tooth 14 structure on both sides of the movable toot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com