Plastic corrugated pipe and preparation method thereof

A bellows and plastic technology, applied in the field of plastic products, can solve the problem of low flame retardant performance of plastic bellows, achieve good fire fighting effect and improve flame retardant efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

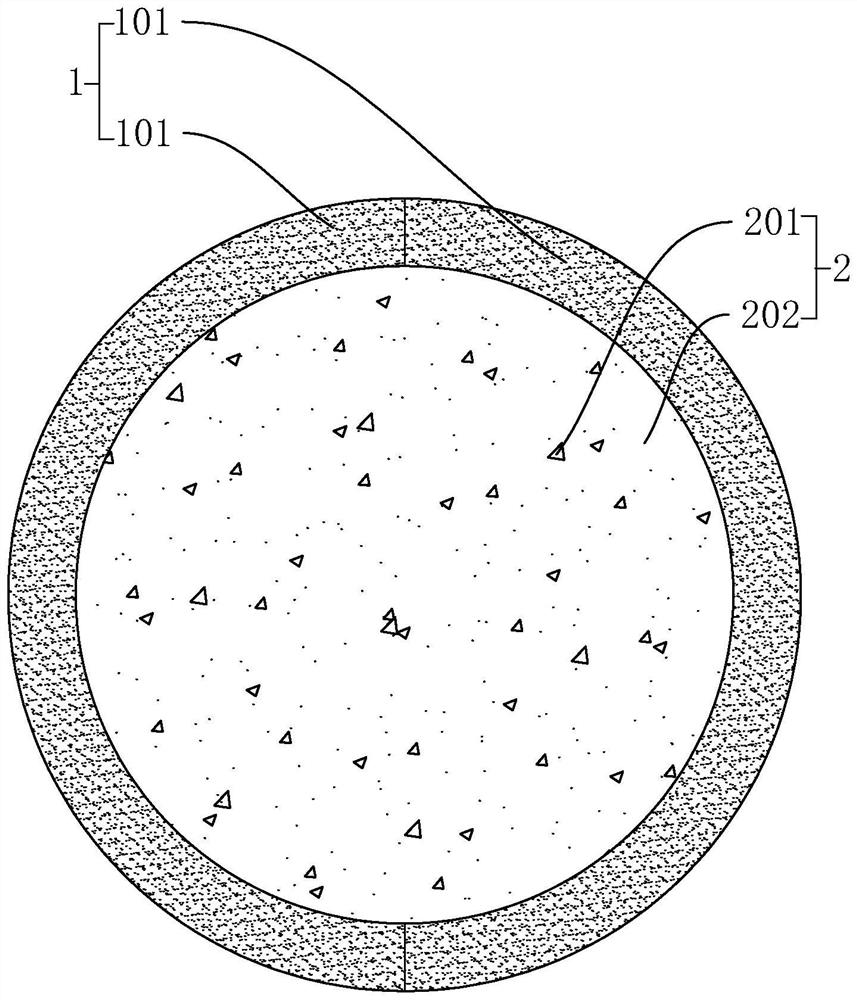

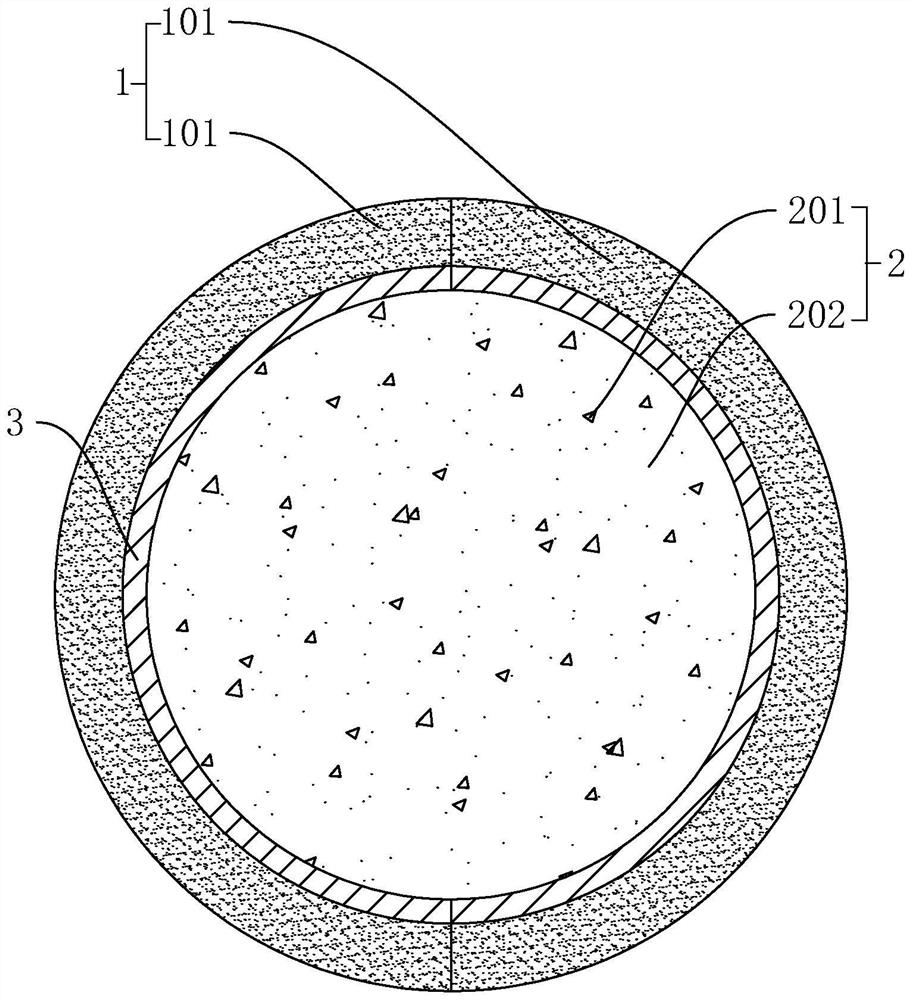

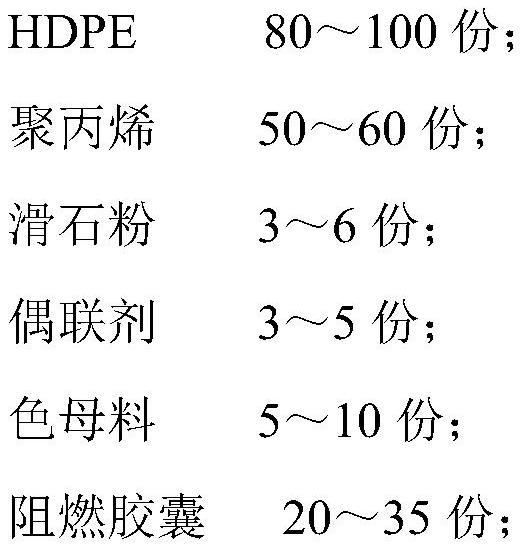

[0039] Embodiment 1: a plastic corrugated pipe, refer to figure 1 , its components and their parts by weight are shown in Table 1. Wherein, the particle size (ie outer diameter) of the flame retardant capsule is 4±1mm, the flame retardant capsule comprises an inner core 2 and a silica gel layer 1 covering the inner core 2, and the inner core 2 is composed of powdery chalazine 201 and powdery effervescent tablets 202 according to The weight ratio is 4:1, and the silica gel layer 1 is formed by enclosing silica gel hemispheres 101 with a softening point above 300°C.

[0040] The preparation steps of the flame retardant capsule are as follows: filling the hollow silica gel hemisphere 101 with powdery cholestyramine 201 and powdery effervescent tablets 202 of corresponding weight, and then filling two pieces of silica gel hemispheres 101 with cholerite 201 and effervescent tablet 202 Cover each other to form a sphere, and use inorganic high temperature adhesive (JL-767B 1460 degr...

Embodiment 2~3

[0050] Examples 2 to 3: a plastic corrugated pipe, which is different from Example 1 in that its components and parts by weight are shown in Table 1.

[0051] Each component and its parts by weight in the embodiment 1-3 of table 1

[0052]

Embodiment 4

[0053] Embodiment 4: a plastic corrugated tube, the difference from Embodiment 1 is that the inner core 2 is formed by mixing the powdery bile alum 201 and the powdery effervescent tablet 202 with a weight ratio of 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com