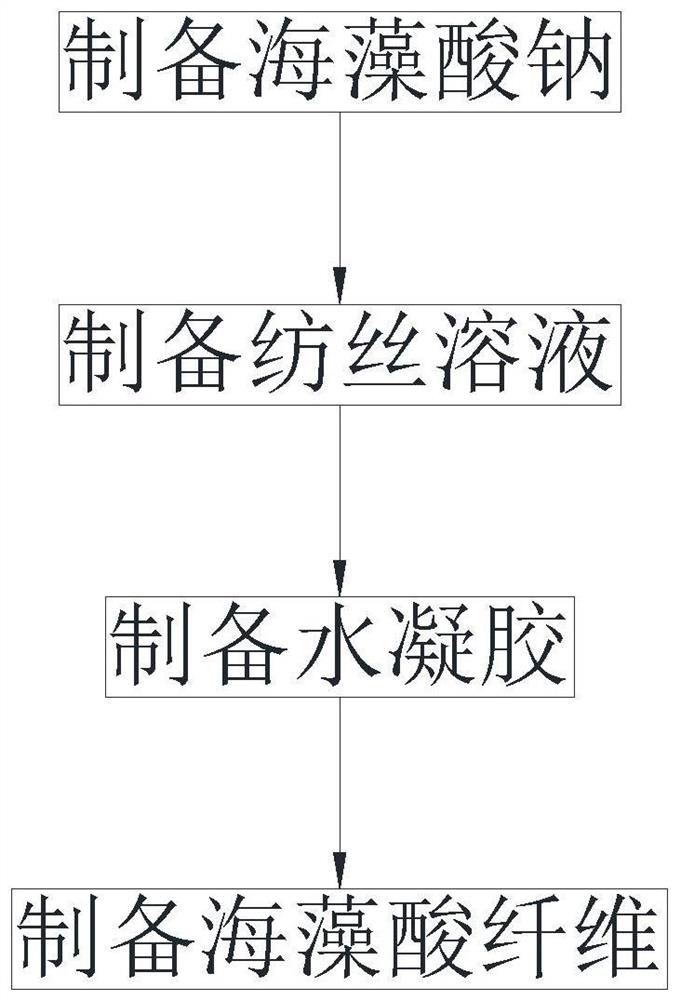

Preparation method of alginic acid fiber

A technology of alginic acid fiber and alginic acid, which is applied in fiber treatment, alginate artificial filament, wet spinning, etc., and can solve the problems of reducing the quality of alginic acid fiber, doping, and reducing the forming efficiency of alginic acid fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of alginate fiber, comprising the following steps:

[0030] S1. To prepare sodium alginate, weigh 1000 parts of seaweed and 500 parts of dilute acid respectively according to the mass fraction, first add the dilute acid to the interior of the seaweed to convert the insoluble alginate into alginic acid, and then add alkali for heating and extraction to generate soluble sodium The salt is dissolved, after filtration, calcium salt is added to generate calcium alginate precipitate, which is converted into insoluble alginic acid by acid treatment, dehydrated and converted into sodium salt by adding alkali, and it is sodium alginate after drying;

[0031] S2. Prepare the spinning solution, then place the sodium alginate inside the water body, increase the water temperature to 50-60°C, and the sodium alginate will completely dissolve into the water body after 1-1.5 hours, thereby forming a mixed solution; The mixed solution is filtered 3-5 times, and at th...

Embodiment 2

[0044] A preparation method of alginate fiber, comprising the following steps:

[0045] S1. To prepare sodium alginate, weigh 1000 parts of seaweed and 800 parts of dilute acid respectively according to the mass fraction, first add the dilute acid to the interior of the seaweed to convert the insoluble alginate into alginic acid, and then add alkali for heating and extraction to generate soluble sodium The salt is dissolved, after filtration, calcium salt is added to generate calcium alginate precipitate, which is converted into insoluble alginic acid by acid treatment, dehydrated and converted into sodium salt by adding alkali, and it is sodium alginate after drying;

[0046] S2. Prepare the spinning solution, then place the sodium alginate inside the water body, increase the water temperature to 50-60°C, and the sodium alginate will completely dissolve into the water body after 1-1.5 hours, thereby forming a mixed solution; The mixed solution is filtered 3-5 times, and at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com