Determination method of phosphorus content

A determination method and technology for phosphorus content, which are applied in chemical analysis by titration, material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc., which can solve the problem of long operation time and easy generation. Error, cumbersome operation process and other problems, to achieve the effect of simple operation and improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a method for measuring phosphorus content, comprising the following steps:

[0027] (1) Sample test: take 0.3017g of ammonium dihydrogen phosphate sample (purity 99%), rinse with water until completely dissolved, add 2 drops of 30% ammonia solution, use NH 3 -NH 4 Cl buffer solution, adjust the pH to 9.8, add 3 drops of chrome black T solution (concentration 10g / L), titrate with 0.1015mol / L magnesium sulfate solution, observe that the color of the solution changes from blue to no more precipitation, and the color of the solution is When the wine turns red, stop the titration, and the volume of magnesium sulfate solution consumed is 25.61 mL;

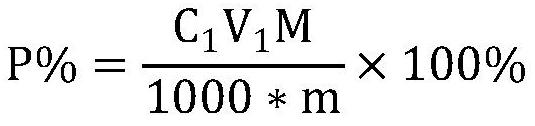

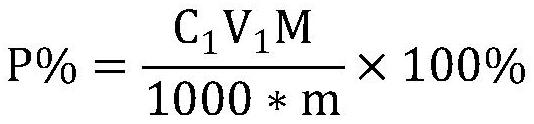

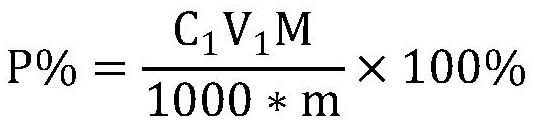

[0028] (2) Calculate the phosphorus content according to the following formula:

[0029]

[0030] Wherein, C1 is the molar concentration of magnesium sulfate solution, V1 is the volume of magnesium sulfate solution consumed in step (1), m is the sample mass consumed, and M is the molar mass of ...

Embodiment 2

[0032] This embodiment provides a method for determining phosphorus content, and the difference from Embodiment 1 is only that the weight of the ammonium dihydrogen phosphate sample (purity 99%) is 0.3126 g.

Embodiment 3

[0034] This embodiment provides a method for determining phosphorus content, and the difference from Embodiment 1 is only that the weight of the ammonium dihydrogen phosphate sample (purity 99%) is 0.3096 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com