Electrode catalyst slurry, preparation method thereof, catalyst coating film and fuel cell

An electrode catalyst, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of catalyst slurry being difficult to ensure uniformity and stability, and achieve high catalyst utilization, stable performance and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

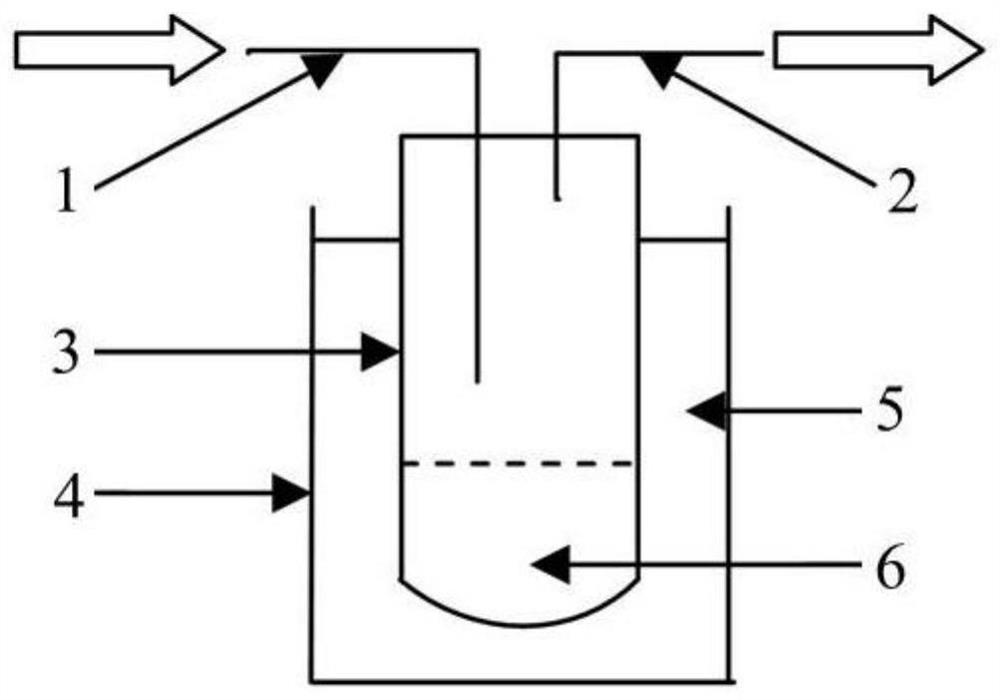

Image

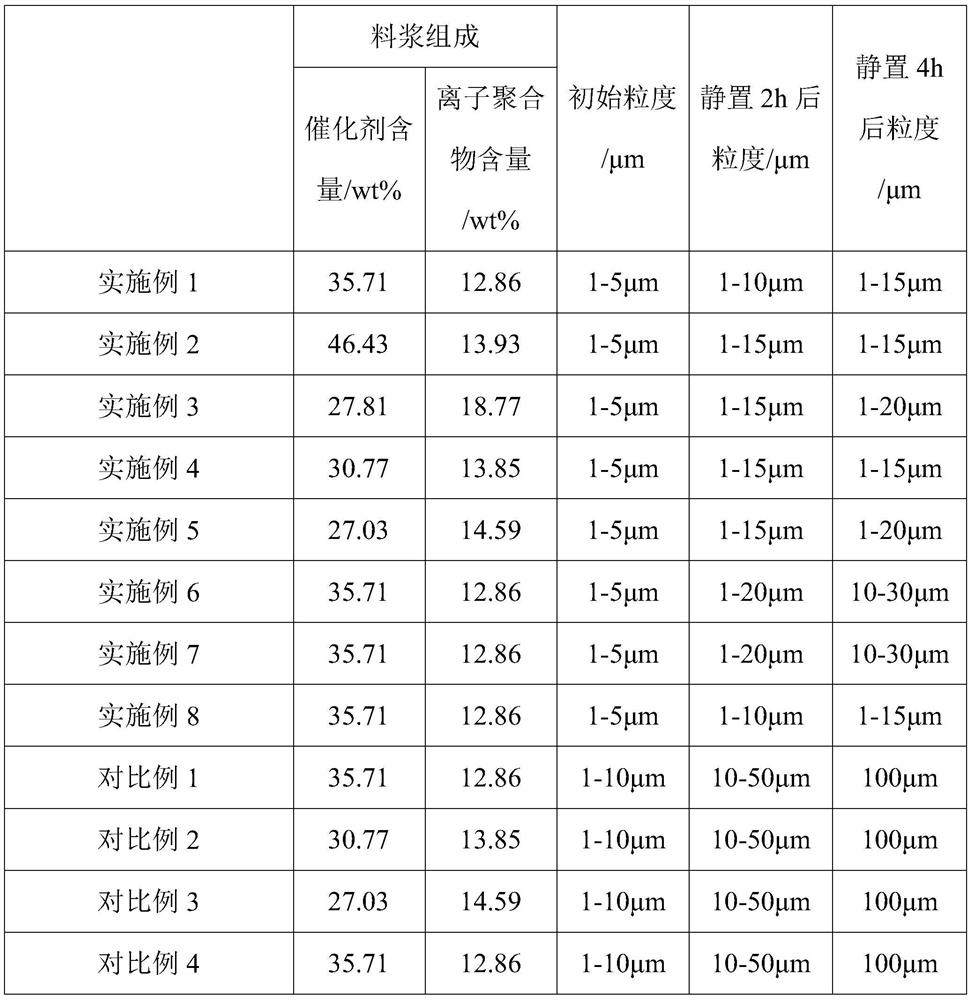

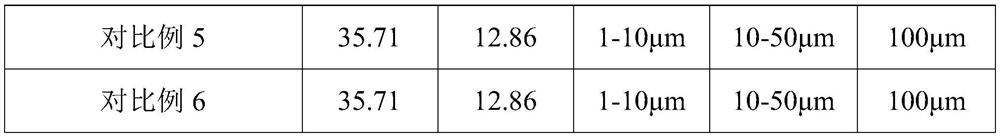

Examples

Embodiment 1

[0084] This embodiment provides a preparation method of electrode catalyst slurry, and the preparation method includes the following steps:

[0085] (1) Add catalyst (the average particle size is 8 μm, platinum alloy catalyst platinum-cobalt-carbon with platinum content of 50w% and cobalt content of 5.0w%) into the container, and then introduce argon to exhaust the air, and then add the ionic polymer. The solution (Chemours-D2020, the solid content is 20%), the mass ratio of the ionic polymer to the carbon in the catalyst is 0.8:1, and at room temperature, the frequency is 26HKz ultrasonic vibration stirring for 15min and 20°C cooling and control conditions. 12000r / min high-speed stirring for 30min to obtain the mixture;

[0086] (2) the mixture material is vacuum-dried at 60°C and less than 133Pa for 30min, and the gas after being evacuated is extracted from the vacuum drying box and then condensed and then passed through a vacuum pump to obtain a catalyst-ionic polymer solid...

Embodiment 2

[0089] This embodiment provides a preparation method of electrode catalyst slurry, and the preparation method includes the following steps:

[0090] (1) First, add a catalyst (a platinum alloy catalyst platinum carbon with an average particle size of 5 μm and a platinum content of 50w%) into the container, then pass in argon to exhaust the air, and then add a solution of ionic polymer (AGC-IC100, solid content is 26%), the mass ratio of the ionic polymer and the carbon in the catalyst is 0.6:1, and the frequency is 30HKz ultrasonic vibration stirring for 10min and 10°C cooling, and the control condition is 10000r / min high-speed stirring for 30min, to obtain a mixed material ;

[0091] (2) the mixture material is vacuum-dried at 65°C and less than 133Pa for 30min, and the gas after vacuuming is extracted from the vacuum drying box and then condensed and then passed through a vacuum pump to obtain a catalyst-ionic polymer solid;

[0092] (3) The catalyst-ionic polymer solid bod...

Embodiment 3

[0094] This embodiment provides a preparation method of electrode catalyst slurry, and the preparation method includes the following steps:

[0095] (1) First add 1000g of catalyst (the average particle size is 8 μm, platinum alloy catalyst platinum cobalt carbon with platinum content of 50w% and cobalt content of 5.0w%) into the large container, then pass argon to exhaust the air, and then add ion polymerization solution (AGC-100, solid content 26%), the mass ratio of the ionic polymer to the carbon in the catalyst is 1.5:1, and the frequency is 26HKz ultrasonic agitation for 25min and 22°C cooling, and the control conditions are 30000r / min high-speed stirring for 30 min to obtain a mixture;

[0096] (2) the mixture material is vacuum-dried at 55°C and less than 133Pa for 60min, and the gas after vacuuming is extracted from the vacuum drying box and then condensed and then passed through a vacuum pump to obtain a catalyst-ionic polymer solid;

[0097] (3) the catalyst-ionic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com