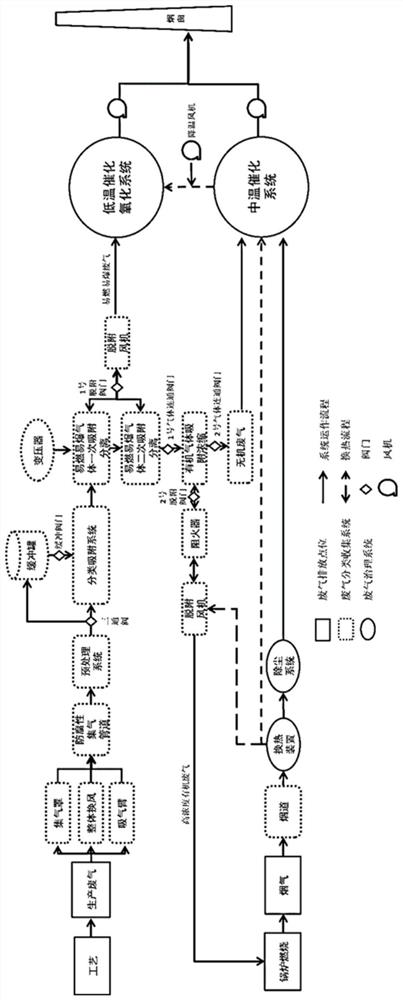

VOCs (volatile organic compounds) general factory waste gas classified collection and treatment system

A treatment system and collection system technology, which is applied in the field of VOCs common factory waste gas classification collection and treatment system, can solve the problems of inapplicable VOCs common factory waste gas treatment, unfavorable common factory operation and promotion, short service life of the treatment system, etc., to achieve purification Remarkable effect, reducing fugitive dispersion and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention is applied to common factories in the packaging and printing industry, and gas-fired boilers are selected. The boiler combustion temperature is 900°C, the flue gas temperature is 400°C, and the initial concentration of flue gas pollutants is CO 5000mg / m 3 , NOx 350mg / m 3 , particulate matter 80mg / m 3 , heavy metal 5mg / m 3 , the initial concentration of waste gas pollutants is VOCs 2000ppm, CO 500mg / m 3 , particulate matter 70mg / m 3 , heavy metal 3mg / m 3 , oil mist 15mg / m 3 , the exhaust gas humidity is 10%, and the VOCs are mainly alkanes.

[0037] The flue gas passes through the flue to the heat exchange device for heat exchange. After the heat exchange, the flue gas is cooled to 50 °C, and then enters the medium temperature catalytic system after being dedusted by the dust removal system. The reaction temperature of the system is 250 °C. The emission concentration of flue gas after purification is CO 150mg / m 3 , NOx 10mg / m 3 , particulate matter...

Embodiment 2

[0039] The invention is applied to common factories in the industrial coating industry, and oil-fired boilers are selected. 3 , NOx 450mg / m 3 , particulate matter 60mg / m 3 , heavy metal 6mg / m 3 , the initial concentration of waste gas pollutants is VOCs 2500ppm, CO 1000mg / m 3 , particulate matter 70mg / m 3 , heavy metal 3mg / m 3 , oil mist 20mg / m 3 , the exhaust gas humidity is 8%, and the VOCs are mainly olefins.

[0040] The flue gas passes through the flue to the heat exchange device for heat exchange. After the heat exchange, the flue gas is cooled to 100 °C, and then enters the medium temperature catalytic system after being dedusted by the dust removal system. The reaction temperature of the system is 350 °C. The emission concentration of flue gas after purification is CO 40mg / m 3 , NOx 9mg / m 3 , particulate matter 1.2mg / m 3 , heavy metal 0.12mg / m 3 . At the same time, the production waste gas is collected by the overall air exchange + gas collecting hood and se...

Embodiment 3

[0042] The invention is applied to common factories in the furniture manufacturing industry, and a special biomass-fired boiler + biomass-fired gasifier is selected. The average combustion temperature of the boiler is 1000 °C, the average flue gas temperature is 450 °C, and the average initial concentration of flue gas pollutants is CO 2300mg / m 3 , NOx 410mg / m 3 , particulate matter 100mg / m 3 , heavy metal 12mg / m 3 , the initial concentration of production waste gas pollutants is VOCs 2300ppm, CO 500mg / m 3 , particulate matter 150mg / m 3 , heavy metal 6mg / m 3 , oil mist 10mg / m 3 , the exhaust gas humidity is 9%, and the VOCs are mainly alkanes and alkynes.

[0043] The flue gas passes through the flue to the heat exchange device for heat exchange. After the heat exchange, the flue gas is cooled to 70 °C, and then enters the medium temperature catalytic system after being dedusted by the dust removal system. The reaction temperature of the system is 300 °C The pollutants re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com